Breaking in new hiking shoes and socks is the most critical preventative step you can take to avoid painful blisters and foot injuries on a long hike. This process isn't just about softening the materials; it's about allowing your footwear to mold to your unique foot shape while simultaneously identifying and addressing any potential high-friction "hot spots" before they can ruin your trip.

The core purpose of breaking in your gear is not just to make it more comfortable, but to run a diagnostic test. You are systematically finding and fixing points of failure in the complex system of your foot, your sock, and your shoe under real-world stress.

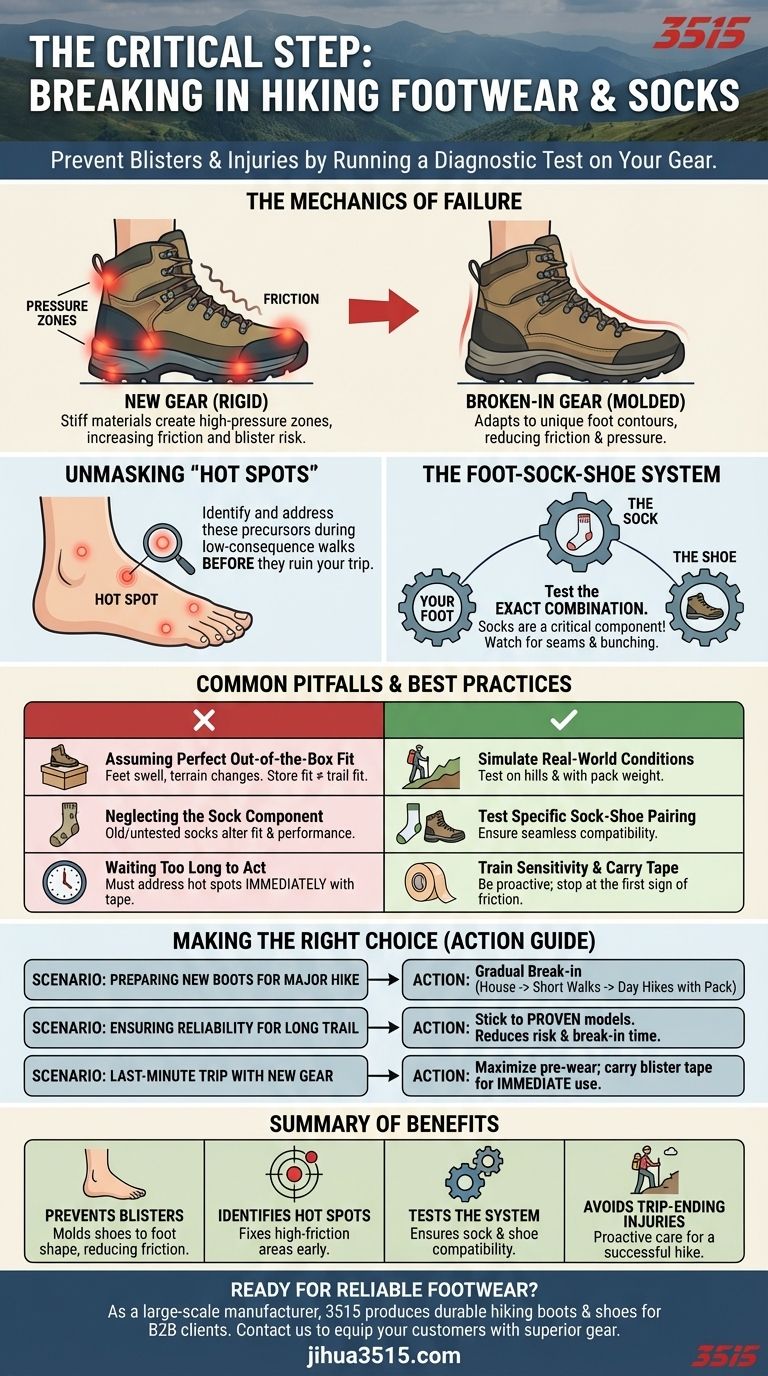

The Mechanics of Footwear Failure

The primary goal of breaking in footwear is to mitigate the factors that lead to blisters: friction, pressure, and moisture. New gear, by its nature, excels at creating these conditions until it is properly adapted to your body.

The Problem of Rigidity

Brand new hiking shoes and boots, particularly those made of leather or stiff synthetic materials, have not yet conformed to the specific contours of your feet. This initial rigidity creates high-pressure zones, especially around the heel, ankle, and toes.

As you walk, your foot moves slightly inside the boot. This movement against a stiff, unyielding surface dramatically increases friction, which is the direct cause of blisters.

Unmasking "Hot Spots"

A "hot spot" is the precursor to a blister—a localized area of warmth, tenderness, or redness caused by friction. The break-in period is your opportunity to discover these hot spots during short, low-consequence walks.

Identifying a hot spot while walking around your neighborhood allows you to make adjustments, try different lacing techniques, or switch socks. Finding one ten miles into a multi-day trek can be a trip-ending disaster.

The Foot-Sock-Shoe System

It is a common mistake to focus only on the shoe. Your footwear operates as a system, and the sock is a critical component.

A new sock might have a seam that rubs you the wrong way, or it might bunch up inside a new shoe, creating an unexpected pressure point. Breaking in your gear means testing the exact combination of socks and shoes you plan to use on your hike.

Common Pitfalls to Avoid

Failing to respect the break-in process is one of the most common mistakes hikers make. Understanding these pitfalls helps clarify why this step is so essential.

Assuming a Perfect Out-of-the-Box Fit

A shoe that feels perfect in the store may reveal significant problems after an hour of walking up and down hills. Your feet swell during a hike, and the forces exerted on them change dramatically on varied terrain.

Only by simulating real-world conditions can you confirm that a good initial fit translates into lasting comfort.

Neglecting the Sock Component

Never test new boots with old, worn-out socks, and never take brand new, untested socks on a long hike. The thickness, material, and seam construction of your sock can completely change how your shoe fits and performs.

Waiting Too Long to Act

The break-in period trains you to be sensitive to the formation of hot spots. If time is short and you must hike with relatively new boots, this sensitivity is crucial.

Carrying blister prevention tape is a good backup plan, but its effectiveness depends on you stopping and applying it the moment you feel the slightest friction, not after the blister has already formed.

Making the Right Choice for Your Hike

Your approach should be dictated by your gear and your timeline. Use these guidelines to prepare effectively for your specific situation.

- If your primary focus is preparing new boots for a major hike: Start by wearing them around the house, then on short walks, and finally on day hikes with the weight of a full pack.

- If your primary focus is ensuring reliability for a long-distance trail: Stick with a shoe model you have used successfully in the past, as this drastically reduces the risk and the break-in period.

- If your primary focus is a last-minute trip with new gear: Wear the shoes and socks as much as possible beforehand and carry blister tape to address any hot spots the second you feel them on the trail.

Properly broken-in footwear transforms your gear from a potential liability into your most reliable asset.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Prevents Blisters | Reduces friction by molding shoes to your unique foot shape. |

| Identifies Hot Spots | Finds and fixes high-friction areas before they become a problem. |

| Tests the Footwear System | Ensures your specific socks and shoes work together comfortably. |

| Avoids Trip-Ending Injuries | Proactive care prevents painful foot issues that can ruin a hike. |

Ready for Your Next Adventure with Reliable Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable hiking boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality, comfortable footwear designed to perform on any trail.

Let us equip you with the reliable gear your customers need. Contact our team today to discuss your footwear requirements and discover how we can support your business with superior products.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What type of socks are recommended for hiking? Choose the Right Sock for Comfort and Blister Prevention

- Why is it important to clean hiking boot outsoles? Ensure Safety and Protect the Environment

- Does ankle support in hiking boots make a significant difference? The Truth About Stability & Injury Prevention

- What are the pros and cons of hiking boots? Weighing Protection Against Weight & Rigidity

- What testing recommendations exist for new trekking shoes? A Systematic Guide to the Perfect Fit

- What are the four reasons not to wear waterproof hiking boots? Avoid Moisture & Comfort Issues

- How does leather treatment benefit hiking boots? Extend Life, Boost Waterproofing & Comfort

- Why is appropriate footwear important when hiking? For Safety, Performance, and Comfort on the Trail