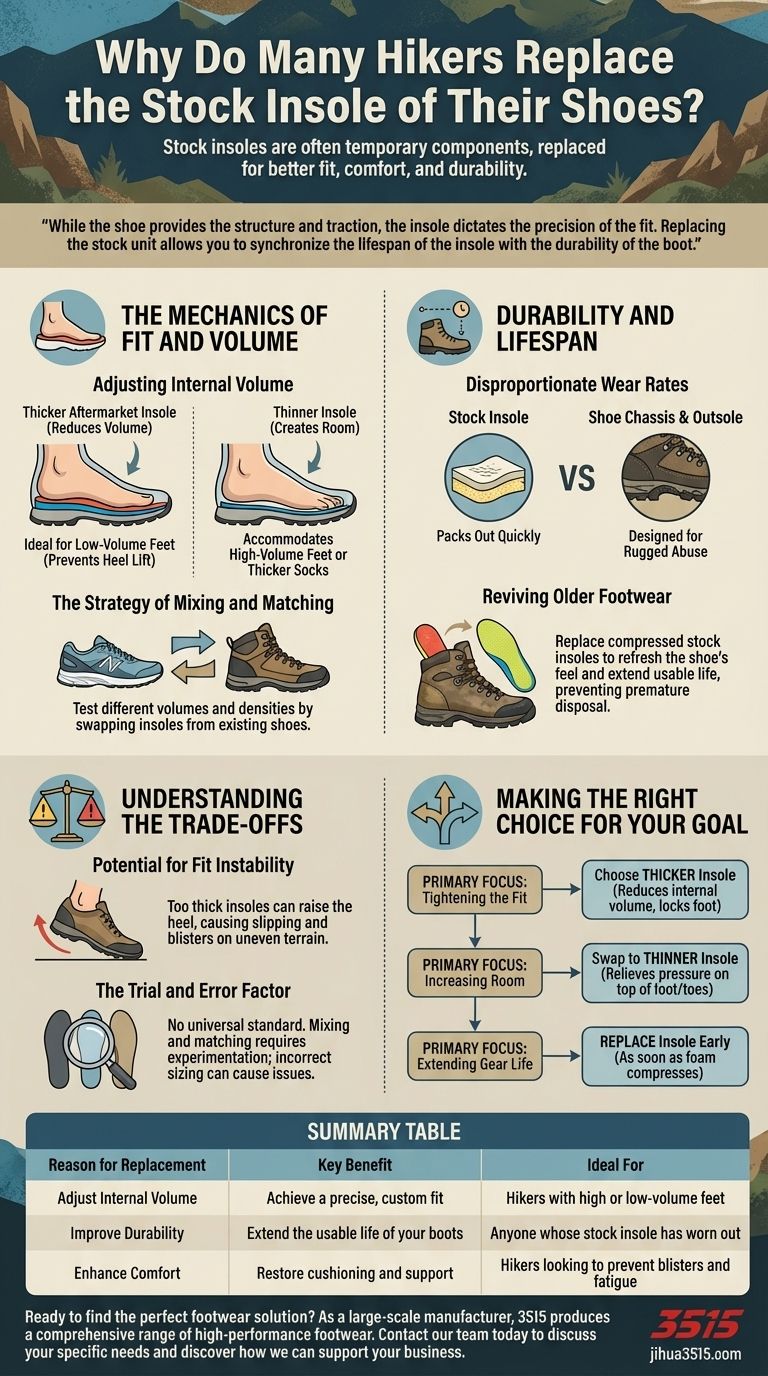

Stock insoles are widely considered temporary components. Hikers frequently replace them because they often degrade and lose effectiveness long before the exterior of the shoe wears out. Furthermore, swapping the insole provides a critical mechanism for customizing the internal volume of the footwear to achieve a precise fit.

While the shoe provides the structure and traction, the insole dictates the precision of the fit. Replacing the stock unit allows you to synchronize the lifespan of the insole with the durability of the boot.

The Mechanics of Fit and Volume

Understanding why hikers switch insoles requires looking at the relationship between foot shape and shoe volume. The stock insole is a generic average, but your foot is unique.

Adjusting Internal Volume

Manufacturers build shoes around a fixed volume, but feet vary in height and width.

Replacing a standard insole with a thicker aftermarket option reduces the open space inside the shoe. This is ideal for hikers with low-volume feet who experience slipping or heel lift.

Conversely, utilizing a thinner insole creates more room. This accommodates higher-volume feet or allows for thicker hiking socks without causing constriction.

The Strategy of Mixing and Matching

You do not always need to purchase a brand-new product to solve a fit problem.

Many hikers successfully mix and match insoles from their existing shoe rotation. Taking an insole from a running shoe and placing it in a hiking boot is a viable, cost-effective way to test different volumes and densities.

Durability and Lifespan

The second major driver for replacement is the discrepancy in material quality between the shoe chassis and the footbed.

Disproportionate Wear Rates

The materials used for the outsole and upper of a hiking shoe are designed for rugged abuse.

However, the stock insole is often made of softer, less durable foam that compresses quickly. It often "packs out," losing its cushioning and thickness, while the rest of the shoe remains structurally sound.

Reviving Older Footwear

Because the insole wears out first, the shoe may feel uncomfortable even if it looks new.

Replacing the compressed stock insole can refresh the feel of the shoe. This extends the usable life of the footwear, preventing premature disposal of expensive gear.

Understanding the Trade-offs

While replacing insoles is common, it introduces variables that can alter the shoe's intended performance.

Potential for Fit Instability

Drastically changing the insole thickness changes where your foot sits inside the shoe.

If you insert an insole that is too thick, you may raise your heel too high, causing it to slip out of the heel cup. This can lead to blisters or instability on uneven terrain.

The Trial and Error Factor

Because there is no universal standard for insole sizing, finding the correct match requires experimentation.

Mixing and matching from other shoes is free, but it may result in imperfect sizing. An insole that is too short will slide around, while one that is too long will bunch up and cause pressure points.

Making the Right Choice for Your Goal

Deciding whether to replace your stock insole depends on the specific problem you are trying to solve with your current footwear.

- If your primary focus is Tightening the Fit: Choose a thicker insole to reduce internal volume and lock your foot in place.

- If your primary focus is Increasing Room: Swap to a thinner insole to relieve pressure on the top of the foot or toes.

- If your primary focus is Extending Gear Life: Replace the insole as soon as the original foam compresses, rather than retiring the entire shoe.

By treating the insole as a replaceable tool rather than a permanent fixture, you gain control over both the comfort and longevity of your hiking footwear.

Summary Table:

| Reason for Replacement | Key Benefit | Ideal For |

|---|---|---|

| Adjust Internal Volume | Achieve a precise, custom fit | Hikers with high or low-volume feet |

| Improve Durability | Extend the usable life of your boots | Anyone whose stock insole has worn out |

| Enhance Comfort | Restore cushioning and support | Hikers looking to prevent blisters and fatigue |

Ready to find the perfect footwear solution?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Whether you need durable hiking boots with replaceable insoles or any other type of shoe, our production capabilities ensure top quality and reliable supply.

Contact our team today to discuss your specific needs and discover how we can support your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What testing recommendations exist for new trekking shoes? A Systematic Guide to the Perfect Fit

- What is the difference between waterproof and water-resistant hiking footwear? Choose the Right Gear for Your Trail

- What are the advantages and disadvantages of high-cut hiking boots? A Guide to Maximum Support vs. Weight

- What are the two main variables to consider when choosing hiking footwear? Find Your Perfect Match

- What alternatives exist for extreme wet conditions beyond waterproof hiking boots? Discover the Best Footwear for Saturated Terrain

- What is a toe cap or rand in hiking boots? Essential Protection for Rugged Trails

- What type of terrain and packing is suitable for low-cut hiking shoes? Perfect for Lightweight Day Hikes

- What factors should one consider when deciding whether to use hiking shoes for walking? Match Your Shoe to Your Path