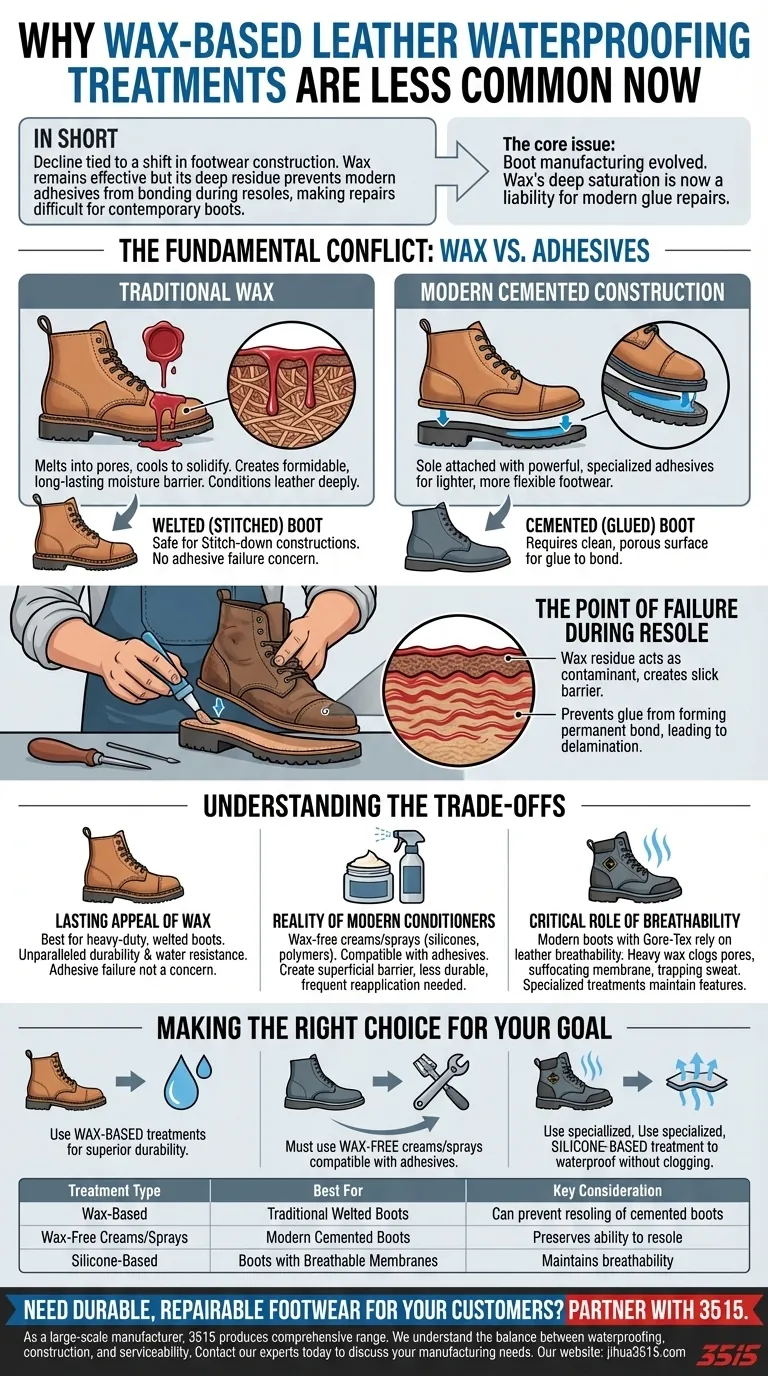

In short, the decline of traditional wax treatments is directly tied to a shift in footwear construction. While wax remains a highly effective waterproofer, its residue deeply penetrates leather and can prevent modern adhesives from bonding during a resole. This complication makes future repairs difficult or even impossible on many contemporary boots.

The core issue isn't that wax stopped working; it's that boot manufacturing evolved. The very quality that makes wax effective—its ability to deeply coat and saturate leather fibers—becomes a critical liability when modern glues are needed for repairs.

The Fundamental Conflict: Wax vs. Adhesives

To understand this shift, you must first recognize the tension between how old-world waterproofing works and how many modern boots are built and repaired.

How Traditional Wax Works

For centuries, wax has been the gold standard for waterproofing leather. When warmed and applied, it melts into the pores of the hide.

As it cools, it solidifies within the leather's fibrous structure, creating a formidable and long-lasting barrier against moisture. This process not only blocks water but also deeply conditions the leather.

The Rise of Cemented Construction

Many modern boots, especially lighter hiking and tactical models, use a method called cemented construction. The sole is attached to the upper using powerful, specialized adhesives.

This technique is efficient and allows for lighter, more flexible footwear compared to traditional welted (stitched) methods.

The Point of Failure

The problem arises during a resole. To attach a new sole to a cemented boot, a cobbler must create a clean, porous surface for the new adhesive to grip.

Wax residue, having penetrated deep into the leather, acts as a contaminant. It creates a slick, non-porous barrier that prevents the glue from forming a permanent chemical bond, leading to sole delamination and repair failure.

Understanding the Trade-offs

Choosing a leather treatment is no longer a simple matter of what works best for waterproofing. It's about balancing performance with long-term serviceability.

The Lasting Appeal of Wax

On the right boot, wax is still an exceptional choice. For heavy-duty, traditionally welted (stitched) footwear, wax-based products offer unparalleled durability and water resistance.

Because these boots are stitched together, adhesive failure is not a concern during a resole, making wax a safe and effective option.

The Reality of Modern Conditioners

Modern, wax-free creams and sprays are formulated to be compatible with adhesives. They often use silicones, polymers, or other synthetic compounds.

These products typically create a more superficial barrier on the leather. While effective, they may be less durable than wax and require more frequent reapplication.

The Critical Role of Breathability

Many modern boots feature waterproof, breathable membranes like Gore-Tex. These membranes rely on the leather's ability to breathe to function properly.

Heavy wax-based treatments can clog the leather's pores, effectively suffocating the membrane and trapping sweat inside the boot. Specialized modern treatments are designed to provide water resistance without compromising this critical feature.

Making the Right Choice for Your Goal

Before treating your leather goods, identify their construction method and intended use. This will guide you to the correct product that enhances performance without compromising future repairs.

- If your primary focus is maximum water resistance on traditionally welted (stitched) boots: Wax-based treatments remain a superior option for durability and leather conditioning.

- If your primary focus is preserving the ability to resole modern, cemented (glued) boots: You must use wax-free creams, lotions, or sprays specifically designed to be compatible with adhesives.

- If your primary focus is maintaining the performance of boots with a breathable membrane: Use a specialized, silicone-based treatment that waterproofs the leather without clogging its pores.

Understanding your footwear's construction is the key to preserving its performance and lifespan.

Summary Table:

| Treatment Type | Best For | Key Consideration |

|---|---|---|

| Wax-Based | Traditional Welted (Stitched) Boots | Can prevent resoling of cemented boots |

| Wax-Free Creams/Sprays | Modern Cemented (Glued) Boots | Preserves ability to resole |

| Silicone-Based | Boots with Breathable Membranes (e.g., Gore-Tex) | Maintains breathability |

Need Durable, Repairable Footwear for Your Customers? Partner with 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We understand the critical balance between waterproofing, construction, and long-term serviceability. Our production capabilities encompass all types of shoes and boots, including traditionally welted designs that are perfectly suited for wax-based treatments, and modern constructions that require specific care.

Let us help you provide your customers with high-quality footwear built for performance and longevity. Contact our experts today to discuss your manufacturing needs.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Dial Closure Leather Business Casual Shoes for Wholesale & Private Label

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What materials are used in snow boots and rain boots? A Guide to Waterproof Footwear

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- What are the characteristics of rubber as a rain boot material? Discover Its Durability & Flexibility

- How do the heights of rain boots and snow boots compare? A Guide to Weather-Ready Footwear