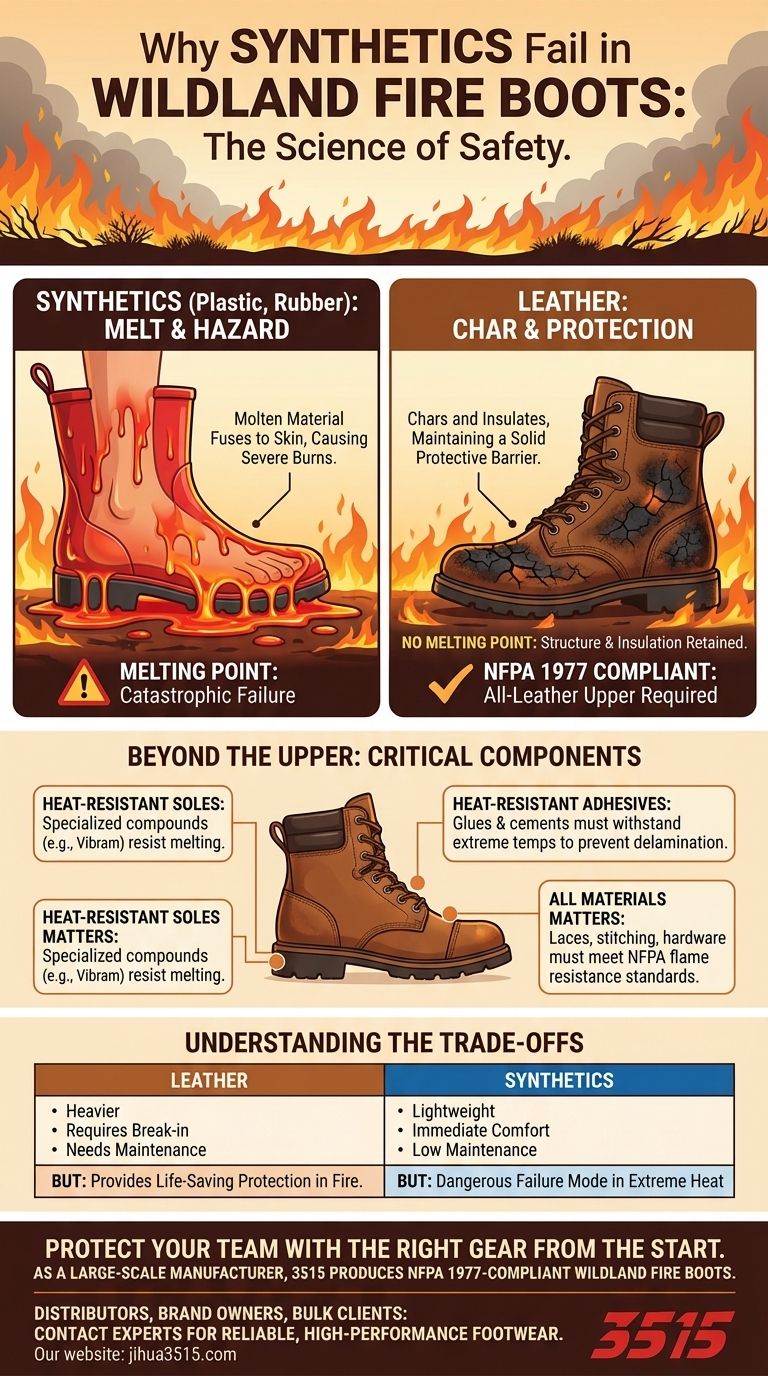

In short, synthetic materials are unsuitable for wildland fire boots because they melt. When exposed to the extreme temperatures of a fireline, plastics and rubbers can liquefy, losing all structural integrity. This catastrophic failure not only exposes the foot to direct heat but can also fuse the molten material to the skin, causing severe, deep-tissue burns.

The choice between leather and synthetics for fire boots is a critical safety decision rooted in material science. Leather chars and insulates under extreme heat, maintaining a protective barrier, while synthetics melt and conduct heat, transforming from protective gear into a direct hazard.

The Physics of Failure: Melting vs. Charring

The core difference in performance comes down to how these two classes of materials react when pushed past their temperature limits. Their failure modes are fundamentally and dangerously different.

The Critical Flaw of Synthetic Materials

Most synthetic materials used in common footwear, like nylon, polyester, and standard rubber compounds, have a specific melting point. When they reach this temperature, they undergo a phase change from a solid to a viscous liquid.

This molten material is superheated and sticky. It readily adheres to socks and skin, ensuring the maximum possible heat is transferred directly to the firefighter's foot. This is why even a small plastic component on a boot can create a dangerous localized hot spot.

How Leather Responds to Heat

Leather, which is a natural animal hide, does not have a melting point. When exposed to extreme heat, it undergoes a process called charring.

The leather dries out, shrinks, and becomes brittle, but it maintains its physical form as a solid barrier. This char layer actually acts as an additional insulator, slowing the transfer of heat to the foot and providing precious extra seconds of protection.

Beyond the Boot's Upper

A boot is a system of components, and every part must be able to withstand the thermal load of a wildfire environment. The unsuitability of synthetics extends to every piece of the boot.

The Sole and Its Adhesives

The boot's sole is in direct contact with the superheated ground. Wildland fire boots use special, high-density, heat-resistant rubber compounds (like those made by Vibram) that are designed to resist melting at high temperatures.

Furthermore, the glues and cements used to attach the sole to the leather upper must also be heat-resistant. Standard footwear adhesives would fail quickly, causing the sole to delaminate and fall off the boot entirely.

Mandates from Safety Standards

These material requirements are not merely suggestions; they are codified in safety regulations. The NFPA 1977 standard, the Standard on Protective Clothing and Equipment for Wildland Fire Fighting, explicitly dictates the materials that can be used.

This standard mandates an all-leather outer construction for the boot upper and sets minimum performance requirements for heat and flame resistance for every component, from the laces to the sole.

Understanding the Trade-offs

Choosing the right material always involves balancing competing priorities. While synthetics fail catastrophically in a fire, they offer benefits in other contexts, which highlights why purpose-built gear is so critical.

The Downside of Leather

Leather is not a perfect material. It is typically heavier than its synthetic counterparts, requires a significant break-in period to become comfortable, and demands regular cleaning and conditioning to maintain its durability and water resistance.

The Appeal of Synthetics (in Other Contexts)

For standard hiking or work boots, modern synthetics are often superior. They are lightweight, require little to no break-in period, and can offer excellent waterproofing with minimal maintenance. These advantages, however, are instantly negated by their dangerous failure mode in a high-heat environment.

Making the Right Choice for Your Goal

Your choice of footwear must be dictated by the specific hazards you expect to face.

- If your primary focus is wildland firefighting or similar high-heat industrial work: You must use NFPA-compliant boots with all-leather uppers and certified heat-resistant soles, as anything else poses a direct safety risk.

- If your primary focus is general hiking, construction, or work in non-fire environments: Modern synthetic or hybrid boots may offer a better balance of light weight, immediate comfort, and performance for those conditions.

Ultimately, understanding how a material fails is the key to selecting equipment that will protect you when you need it most.

Summary Table:

| Material | Reaction to Extreme Heat | Result for Firefighter |

|---|---|---|

| Synthetics (Plastic, Rubber) | Melts and liquefies | Fuses to skin, causing severe burns |

| Leather | Chars and hardens | Maintains a protective, insulating barrier |

Protect your team with the right gear from the start.

As a large-scale manufacturer, 3515 produces NFPA 1977-compliant wildland fire boots with all-leather uppers and certified heat-resistant soles. We ensure every component, from the leather to the adhesives, is engineered for maximum safety on the fireline.

Are you a distributor, brand owner, or bulk client needing reliable, high-performance safety footwear? Contact our experts today to discuss your requirements and get a quote for boots built to withstand the extreme.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

People Also Ask

- What should you check for when testing the fit of new work boots? Ensure All-Day Comfort and Safety

- What are the sizing and fit considerations for women's work boots? A Safety & Comfort Guide

- What are some tips for measuring and fitting work boots correctly? Ensure All-Day Comfort and Safety

- What factors should be considered when choosing cowboy boots for work? Find the Perfect Fit for Safety & Comfort

- What kind of boots do Wildland firefighters wear? The Ultimate Guide to NFPA 1977 Certified Footwear

- How does routine boot maintenance benefit workplace safety? Proactive PPE Protection for Your Workforce

- What is Stitch-down Construction in work boots? Discover the Ultimate Durability and Stability

- What should be considered regarding size when choosing PVC work boots? Ensure a Perfect Fit for Safety & Comfort