The primary reason PVC work boots are considered comfortable is their material composition. Polyvinyl chloride (PVC) is an inherently soft, flexible polymer, which allows the boot to conform to the foot without the stiff, rigid break-in period required by materials like traditional leather. This immediate pliability reduces pressure points and enhances wearability from the very first use.

While PVC’s natural softness provides a comfortable foundation, true, all-day comfort is not a property of the material alone. It is the result of a complete design system, including ergonomic footbeds, supportive insoles, and modern moisture-wicking linings that work together to support your foot.

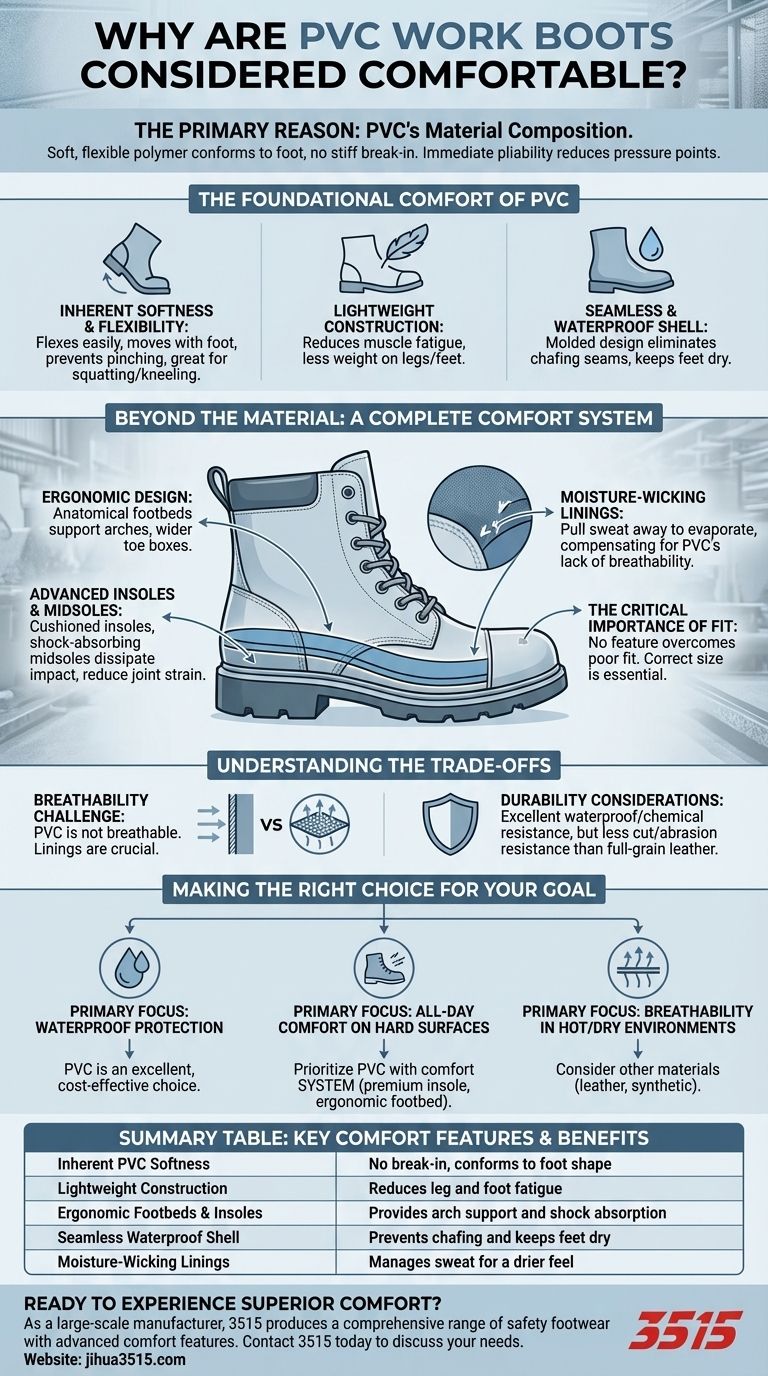

The Foundational Comfort of PVC

The comfort of a PVC boot begins with the core attributes of the material itself. Unlike materials that must be "tamed" over time, PVC offers comfort by its very nature.

Inherent Softness and Flexibility

PVC is a naturally pliable plastic. This means it flexes easily with the movement of your foot, preventing the pinching and rubbing that often occurs with more rigid boot materials.

This flexibility is especially beneficial during tasks that require frequent squatting or kneeling, as the boot moves with you rather than against you.

Lightweight Construction

Compared to heavy-duty leather or rubber alternatives, PVC is a relatively lightweight material. This reduction in weight translates directly to less muscle fatigue in your legs and feet over the course of a long workday.

Seamless and Waterproof Shell

Many PVC boots are manufactured using a molding process, which creates a single, seamless shell. This design eliminates stitched seams that can chafe or allow water to penetrate, providing both comfort and reliable waterproof protection.

Why Material Isn't the Whole Story

A boot's material is only the starting point. Reputable manufacturers integrate additional design features to elevate a simple PVC shell into a high-performance piece of footwear.

The Role of Ergonomic Design

Modern work boots often feature ergonomic designs that support the natural structure of the human foot. This includes anatomical footbeds that conform to your arches and wider toe boxes that allow your toes to splay naturally, reducing pressure and discomfort.

Advanced Insoles and Midsoles

Inside the boot, high-quality cushioned insoles and shock-absorbing midsoles are critical. These components work together as a system to dissipate the impact of walking on hard surfaces, significantly reducing fatigue and strain on your joints.

The Critical Importance of Fit

No design feature can overcome a poor fit. A boot that is too tight will restrict circulation, while one that is too loose will cause your foot to slide, leading to blisters. Comfort is impossible without the correct size and shape for your foot.

Understanding the Trade-offs of PVC

While comfortable, PVC has inherent limitations that must be managed through intelligent boot design. Understanding these trade-offs is key to choosing the right product.

The Breathability Challenge

The primary drawback of PVC is that it is not breathable. As a solid, waterproof plastic, it does not allow air or moisture vapor to escape. This can lead to a hot, sweaty environment inside the boot.

How Linings Compensate

To solve the breathability problem, manufacturers install advanced moisture-wicking linings. These fabrics are designed to pull sweat away from your skin and spread it across a larger surface area, helping it to evaporate and keeping your feet feeling drier and more comfortable.

Durability Considerations

While excellent for many applications, PVC may not offer the same level of resistance to cuts, punctures, and abrasion as premium full-grain leather. Its primary strengths are in waterproofness and chemical resistance rather than extreme physical durability.

Making the Right Choice for Your Goal

When selecting a work boot, consider the complete system, not just the outer material. Your specific work environment and needs should guide your decision.

- If your primary focus is waterproof protection in wet conditions: A well-designed PVC boot is an excellent and often cost-effective choice.

- If your primary focus is all-day comfort on hard surfaces: Prioritize a PVC boot that advertises its comfort system, including a premium insole and an ergonomic footbed.

- If your primary focus is breathability in a hot, dry environment: You may find that a boot made from a different material, like leather or a synthetic textile, better suits your needs.

Ultimately, judging a boot by its shell material alone is like judging a vehicle solely by its frame; the features within are what create a truly comfortable experience.

Summary Table:

| Key Comfort Feature | Benefit |

|---|---|

| Inherent PVC Softness | No break-in period, conforms to foot shape. |

| Lightweight Construction | Reduces leg and foot fatigue. |

| Ergonomic Footbeds & Insoles | Provides arch support and shock absorption. |

| Seamless Waterproof Shell | Prevents chafing and keeps feet dry. |

| Moisture-Wicking Linings | Manages sweat for a drier feel. |

Ready to experience the superior comfort of professionally designed PVC work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work shoes and boots, integrating advanced comfort features directly into our designs.

We can help you provide your customers with durable, comfortable footwear that supports them throughout their workday.

Contact 3515 today to discuss your specific needs and discover how our manufacturing expertise can benefit your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- What is the origin of engineer boots? Born in the 1930s for Industrial Workers

- What does metatarsal protection (MT) in boots safeguard against? Shielding Your Foot's Top Bones

- What factors contribute to the comfort and fit of work boots? Key Components for All-Day Support

- What safety features should be considered when selecting work boots? A Guide to Toe, Electrical & Slip Protection

- What should be considered when choosing work boot materials? A Guide to Safety & Durability

- Why are heavy duty work boots important in high-risk environments? Essential PPE for Ultimate Safety

- Are cowboy boots ok for work? A Guide to Professional Style and Workplace Safety

- What are toe caps in work boots and why are they important? Choose the Right Protection for Your Job