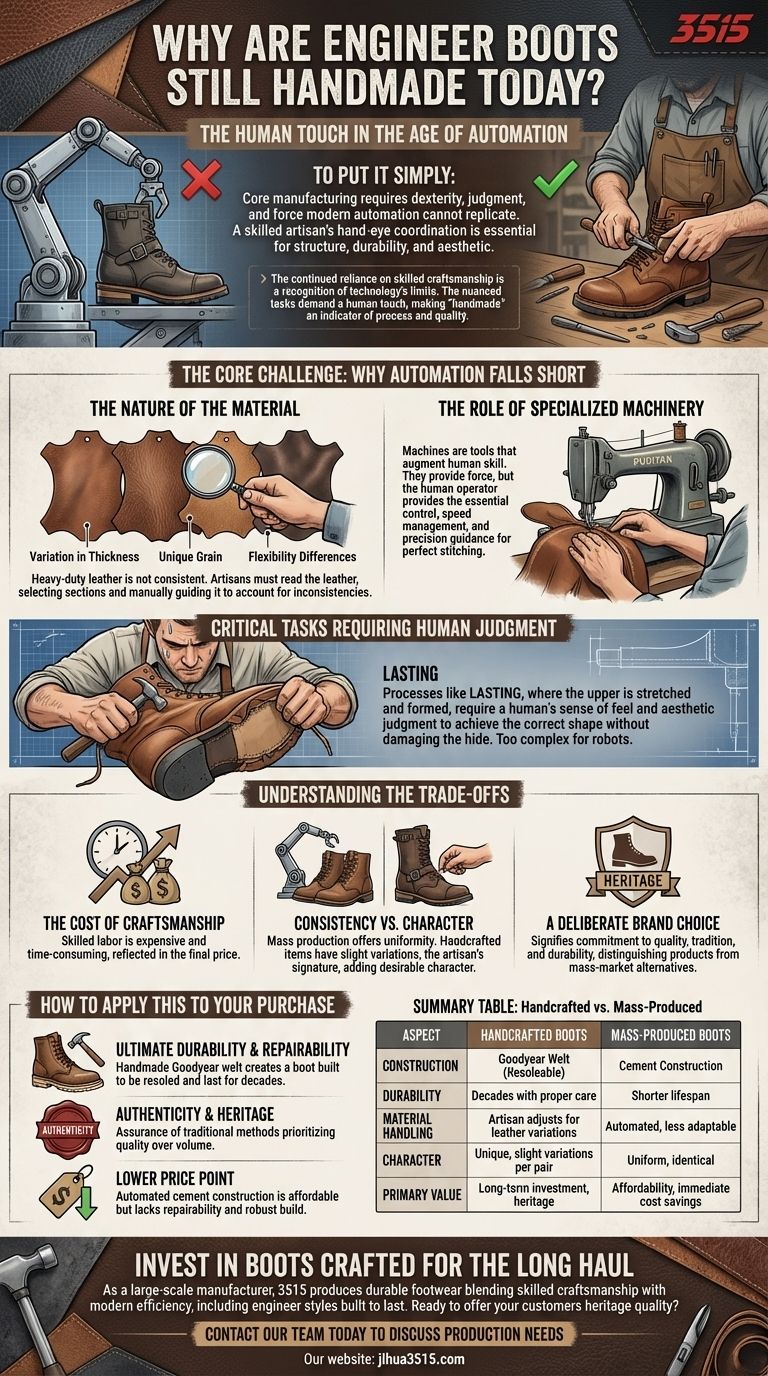

To put it simply, engineer boots are still handmade because the core manufacturing process requires a level of dexterity, judgment, and force that modern automation cannot yet replicate. Working with thick, unforgiving leather involves numerous stages where a skilled artisan's hand-eye coordination is essential to ensure the boot's structure, durability, and final aesthetic.

The continued reliance on skilled craftsmanship is not a resistance to technology, but a recognition of its limits. The nuanced tasks of shaping and stitching heavy leather demand a human touch, making the "handmade" label a direct indicator of both the manufacturing process and the final quality.

The Core Challenge: Why Automation Falls Short

Full automation excels with uniform materials and predictable, repetitive tasks. The process of making a high-quality engineer boot, however, is defined by variability and the need for constant, subtle adjustments.

The Nature of the Material

Heavy-duty leather is not a consistent industrial material like plastic or sheet metal. Each hide has unique characteristics—variations in thickness, grain, and flexibility.

A skilled craftsperson must read the leather, selecting the right sections for different parts of the boot and manually guiding it through machinery to account for these inconsistencies.

The Role of Specialized Machinery

The process isn't devoid of machines, but they are tools that augment human skill rather than replace it. For example, traditional Puritan sewing machines are powerful enough to stitch through thick layers of leather.

However, these machines require an operator with immense skill to guide the boot, manage the speed, and ensure the stitch is perfect. The machine provides the force, but the human provides the control and precision.

Critical Tasks Requiring Human Judgment

Several key stages in bootmaking are simply too complex for current robotic technology. This includes tasks like "lasting," where the leather upper is stretched and formed over the boot's last (the mold).

This requires a combination of pulling, shaping, and securing that relies on a human's sense of feel and aesthetic judgment to achieve the correct shape without damaging the hide.

Understanding the Trade-offs

Opting for a handcrafted process over a fully automated one involves a clear set of compromises that directly impact the final product and the consumer.

The Cost of Craftsmanship

The most obvious trade-off is cost. Skilled labor is expensive and time-consuming. A single pair of boots passes through many hands, each performing a specialized task, which is reflected in the final price tag.

Consistency vs. Character

While mass production delivers near-perfect uniformity, handcrafted items possess slight variations. These are not defects but rather the signature of the artisan. This "handmade character" is a desirable feature for many, but it means no two pairs are ever truly identical.

A Deliberate Brand Choice

For heritage brands, the handmade process is a core part of their identity. It serves as a powerful selling point, signifying a commitment to quality, tradition, and durability that distinguishes their products from mass-market alternatives.

How to Apply This to Your Purchase

Understanding the reason for handcrafting helps you make a more informed decision based on what you truly value in a pair of boots.

- If your primary focus is ultimate durability and repairability: The skilled application of a Goodyear welt in a handmade process creates a boot that is built to be resoled and can last for decades.

- If your primary focus is authenticity and heritage: The "handmade" label is your assurance that the boot was made following traditional methods that prioritize quality over volume.

- If your primary focus is a lower price point: A boot made with more automated processes, like cement construction, will be more affordable but lacks the repairability and robust build of a handcrafted one.

Choosing an engineer boot is an investment in a specific philosophy of manufacturing, where the limits of automation define the value of human skill.

Summary Table:

| Aspect | Handcrafted Boots | Mass-Produced Boots |

|---|---|---|

| Construction | Goodyear Welt (Resoleable) | Cement Construction |

| Durability | Decades with proper care | Shorter lifespan |

| Material Handling | Artisan adjusts for leather variations | Automated, less adaptable |

| Character | Unique, slight variations per pair | Uniform, identical |

| Primary Value | Long-term investment, heritage | Affordability, immediate cost savings |

Invest in Boots Crafted for the Long Haul

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities, blending skilled craftsmanship with modern efficiency, encompass all types of durable shoes and boots, including engineer styles built to last.

Ready to offer your customers footwear that combines heritage quality with reliable supply?

Contact our team today to discuss your production needs and how we can partner to deliver exceptional value and durability.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

People Also Ask

- How does cushioning in work boots degrade, and why should it be checked? Protect Your Feet from Hidden Wear

- Why is hemp fiber considered an ideal reinforcement material? Discover the Lightweight Secret of High-Performance Boots

- What insulation level is suitable for moderate cold weather? The 400g Standard Explained

- Why is traction important in work boots, and what sole features enhance it? Find the Right Sole for Your Job

- What are some tips for maintaining work boots? Extend Lifespan & Maximize Performance

- What are the advantages of soft-toe boots? Superior comfort and flexibility for low-hazard work.

- What are the temperature ratings and recommended uses for 1,000g insulated boots? Stay Warm in Extreme Cold

- What are the three main types of toe caps? Steel, Composite, or Aluminum for Your Work Boots