At their core, composite toe work boots are better for extreme weather because their materials are poor thermal conductors. Unlike steel, which readily transfers heat and cold from the environment directly to your foot, composite materials like carbon fiber, Kevlar, or plastic act as a buffer, helping to maintain a more stable and comfortable temperature inside the boot.

The fundamental difference is not about weatherproofing the boot itself, but about the thermal properties of the safety toe cap. Steel conducts temperature, while composite insulates against it, making it the superior choice for comfort in extreme heat or cold.

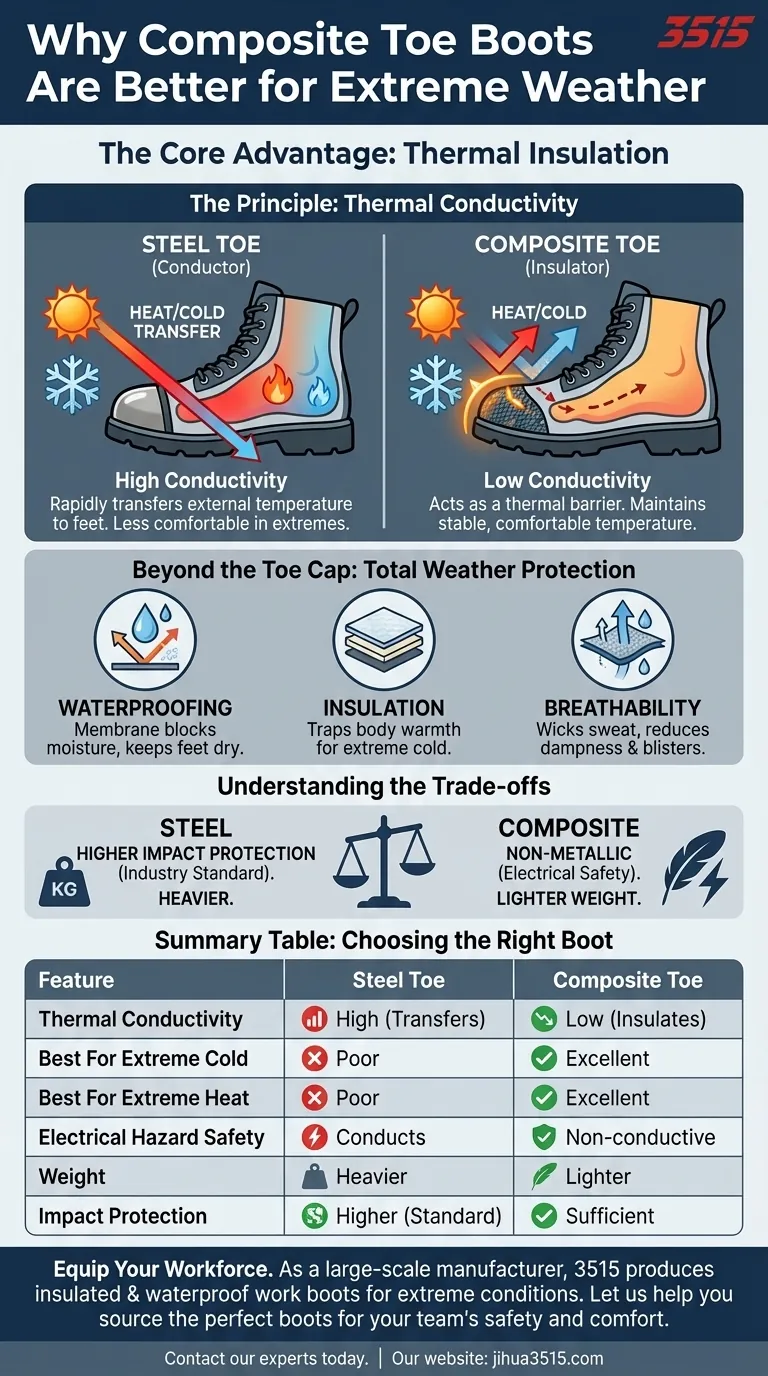

The Principle of Thermal Conductivity

The primary advantage of composite materials in extreme weather comes down to a single scientific principle: thermal conductivity. This is the measure of a material's ability to transfer heat.

How Steel Toes Transfer Temperature

Think of a metal spoon in a hot cup of coffee. The handle quickly becomes hot because steel is an excellent thermal conductor.

A steel toe cap behaves in the same way. In freezing conditions, it draws warmth away from your toes, making your feet feel colder. In intense heat, it absorbs external heat and transfers it inward.

Why Composite Toes Act as an Insulator

Composite materials are poor thermal conductors. They resist the transfer of heat energy, acting as a barrier between your foot and the outside temperature.

This insulation means that in cold weather, your body's warmth is kept inside the boot. In hot weather, the heat from the sun or hot surfaces is significantly slowed from reaching your foot.

Beyond the Toe Cap: Total Weather Protection

While the toe material is critical for thermal comfort, a truly weather-ready boot incorporates several other essential features.

Waterproofing vs. Water Resistance

Many boots feature water-resistant leather, which can handle light rain or damp conditions.

For truly wet environments, look for a dedicated waterproof boot. These often include an internal membrane or bootie that completely blocks moisture from entering, keeping your feet dry.

The Role of Insulation in Extreme Cold

For work in snow or freezing temperatures, the boot's insulation level is paramount.

Some dedicated winter work boots feature additional insulation layers or even separate inner liners, providing a level of warmth far superior to standard boots.

Breathability and Moisture Wicking

In both hot and cold conditions, managing sweat is crucial for comfort and safety.

Materials that are breathable and have moisture-wicking properties pull sweat away from the skin. This prevents the damp, chilled feeling in winter and reduces blisters and discomfort in the heat.

Understanding the Trade-offs

Choosing composite toe boots for their thermal benefits involves accepting a key trade-off against traditional steel toes.

Impact Protection: Steel vs. Composite

While all safety toes must meet OSHA and ASTM safety standards, steel generally offers a higher level of resistance to extreme impact and crushing forces.

Composite toes provide sufficient protection for most scenarios, but steel remains the top choice for environments with the highest risk of heavy falling objects.

Electrical Hazard Protection

A significant advantage of composite materials is that they are non-metallic.

This makes composite toe boots the standard choice for electricians, engineers, and anyone working near live circuits, as they do not conduct electricity.

The Weight Factor

Composite toe caps are typically lighter than steel. While the difference may seem minor, it can reduce foot fatigue over a long workday, contributing to overall comfort and endurance.

Making the Right Choice for Your Environment

Ultimately, the best boot depends entirely on the specific hazards and conditions of your workplace.

- If your primary focus is working in extreme heat or cold: Choose composite toes for their superior thermal insulation and comfort.

- If your primary focus is maximum impact and crush protection: Steel toes remain the industry standard for the highest level of safety from heavy objects.

- If you work around live electrical circuits: Non-metallic composite toes are the essential choice for mitigating electrical hazards.

- If you work in consistently wet conditions: Prioritize boots with a true waterproof membrane over those that are only water-resistant.

Choosing the right boot means matching the material's properties to the specific demands of your job site.

Summary Table:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Thermal Conductivity | High (transfers heat/cold) | Low (insulates) |

| Best For Extreme Cold | Poor | Excellent |

| Best For Extreme Heat | Poor | Excellent |

| Electrical Hazard Safety | Conducts electricity | Non-conductive |

| Weight | Heavier | Lighter |

| Impact Protection | Higher (Industry Standard) | Sufficient for most jobs |

Equip your workforce with the right protection for any environment.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of insulated and waterproof work boots designed for extreme weather conditions.

Let us help you source the perfect composite toe boots for your team's safety and comfort. Contact our experts today to discuss your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How should cowboy boots be maintained for farm work? A Practical Guide to Extend Their Lifespan

- What craftsmanship elements define quality in cowboy boots? The Markers of True Durability & Style

- What are the experiences of users with high-end biking-specific boots? A Deep Dive into Durability, Warmth, and Value

- What makes Western-style work boots comfortable? Unlock All-Day Comfort with Advanced Design

- How do work boots protect against common construction hazards? A Guide to Essential Foot Safety

- What are the key features of Western work boots? A Hybrid of Style, Safety & Comfort

- How do Chemical Resistant boots ensure comfort during long workdays? Achieve All-Day Comfort & Safety

- What are the temperature ratings and recommended uses for 600g insulated boots? A Guide to Staying Warm & Dry