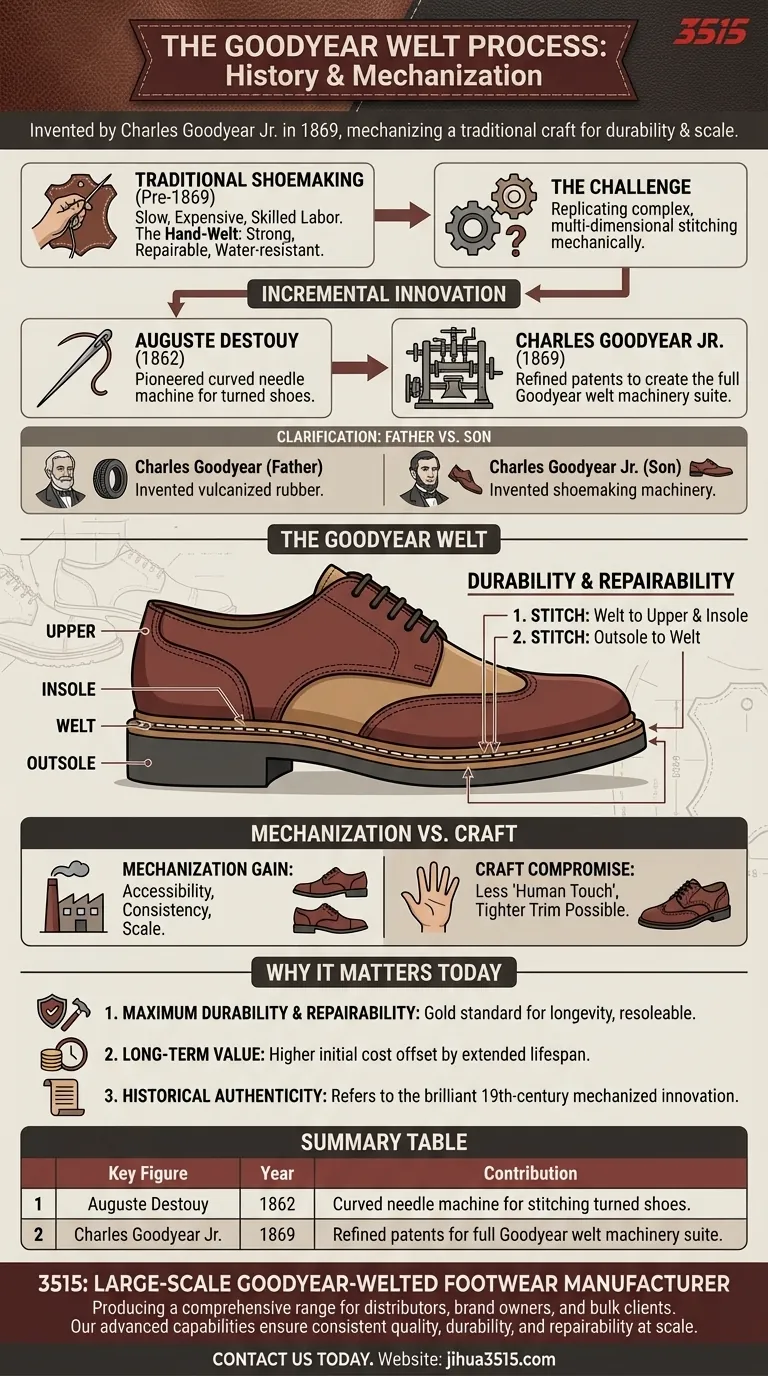

While the name is famous, the machinery for the Goodyear welt process was invented by Charles Goodyear Jr. in 1869. He successfully mechanized a complex, traditional shoemaking technique, building upon the foundational work of earlier inventors like Auguste Destouy. This innovation did not create a new way to make shoes, but rather a way to produce highly durable, repairable footwear with unprecedented speed and consistency.

The invention of the Goodyear welt machinery was not a single "eureka" moment, but the critical final step in industrializing a centuries-old craft. It represents the successful translation of complex hand-sewn principles into a reliable, mechanical process.

The Problem: The Limits of Traditional Shoemaking

Before the mid-19th century, durable and water-resistant footwear was a product of intense manual labor. Understanding this context reveals why mechanization was such a profound breakthrough.

The Art of the Hand-Welt

The most robust method involved hand-stitching a leather strip, or welt, to the shoe's upper and insole. The outsole was then stitched to this welt.

This created a remarkably strong, water-resistant, and—most importantly—repairable shoe, as the outsole could be replaced without compromising the upper.

The Challenge of Mechanization

This process was slow, expensive, and required highly skilled artisans. Replicating the intricate, multi-dimensional stitching required to join the welt through thick leather was a significant mechanical challenge that stymied early inventors.

The Path to Invention: A Story of Incremental Innovation

Charles Goodyear Jr.'s success was not born in a vacuum. It was the culmination of key developments that solved the puzzle of mechanizing the welt.

The Foundational Concept by Auguste Destouy

A major precursor was a machine invented by Auguste Destouy in 1862. It featured a curved needle capable of stitching turned shoes, demonstrating the basic principle needed for a welting machine.

The Breakthrough by Charles Goodyear Jr.

In 1869, Charles Goodyear Jr. acquired and refined patents, including Destouy's, to create a suite of machinery that could specifically replicate the hand-welting process. His machines could stitch the welt to the upper and insole with remarkable precision.

This was the pivotal invention that made Goodyear-welted footwear scalable, transforming the industry.

Clarifying the Name: Father vs. Son

It is a common point of confusion, but Charles Goodyear, the father, is famous for inventing vulcanized rubber. It was his son, Charles Goodyear Jr., who applied his innovative spirit to the problem of shoemaking machinery.

Understanding the Trade-offs: Mechanization vs. Craft

Automating any craft involves compromises. The Goodyear welt is a prime example of balancing industrial efficiency with artisanal tradition.

The Gain: Accessibility and Consistency

The primary benefit was scale. The Goodyear welt machine made exceptionally durable and resoleable footwear accessible to a much broader market, not just the wealthy. It also introduced a high level of consistency impossible to achieve with handwork alone.

The Compromise: The Human Touch

While mechanically sound, some purists argue that machine-stitching lacks the finer control and tensioning of a master cobbler's handwork. Hand-welting allows for a tighter, closer-trimmed welt that some connoisseurs prefer for its sleeker profile.

How This History Informs Your Choice Today

Understanding the origin of the Goodyear welt allows you to appreciate its purpose and make a more informed decision when investing in high-quality footwear.

- If your primary focus is maximum durability and repairability: The Goodyear welt remains the gold standard for footwear designed to be resoled multiple times, offering unparalleled longevity.

- If your primary focus is value over the long term: The higher initial cost of a Goodyear-welted shoe is often offset by its extended lifespan, as you are buying a repairable product, not a disposable one.

- If your primary focus is historical authenticity: Recognize that the "Goodyear welt" specifically refers to the mechanized process, a brilliant 19th-century innovation distinct from the older, purely hand-sewn tradition.

Knowing this history transforms a simple shoe into a tangible piece of industrial innovation.

Summary Table:

| Key Figure | Year | Contribution |

|---|---|---|

| Auguste Destouy | 1862 | Pioneered curved needle machine for stitching turned shoes. |

| Charles Goodyear Jr. | 1869 | Refined patents to create the full Goodyear welt machinery suite. |

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear-welted footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities ensure the durability and repairability that define this classic method, delivering consistent quality at scale. Contact us today to discuss how we can meet your footwear needs with reliable, long-lasting solutions.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- Why might someone prefer rubber soles over leather soles? Unlock Durability & All-Weather Performance

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability