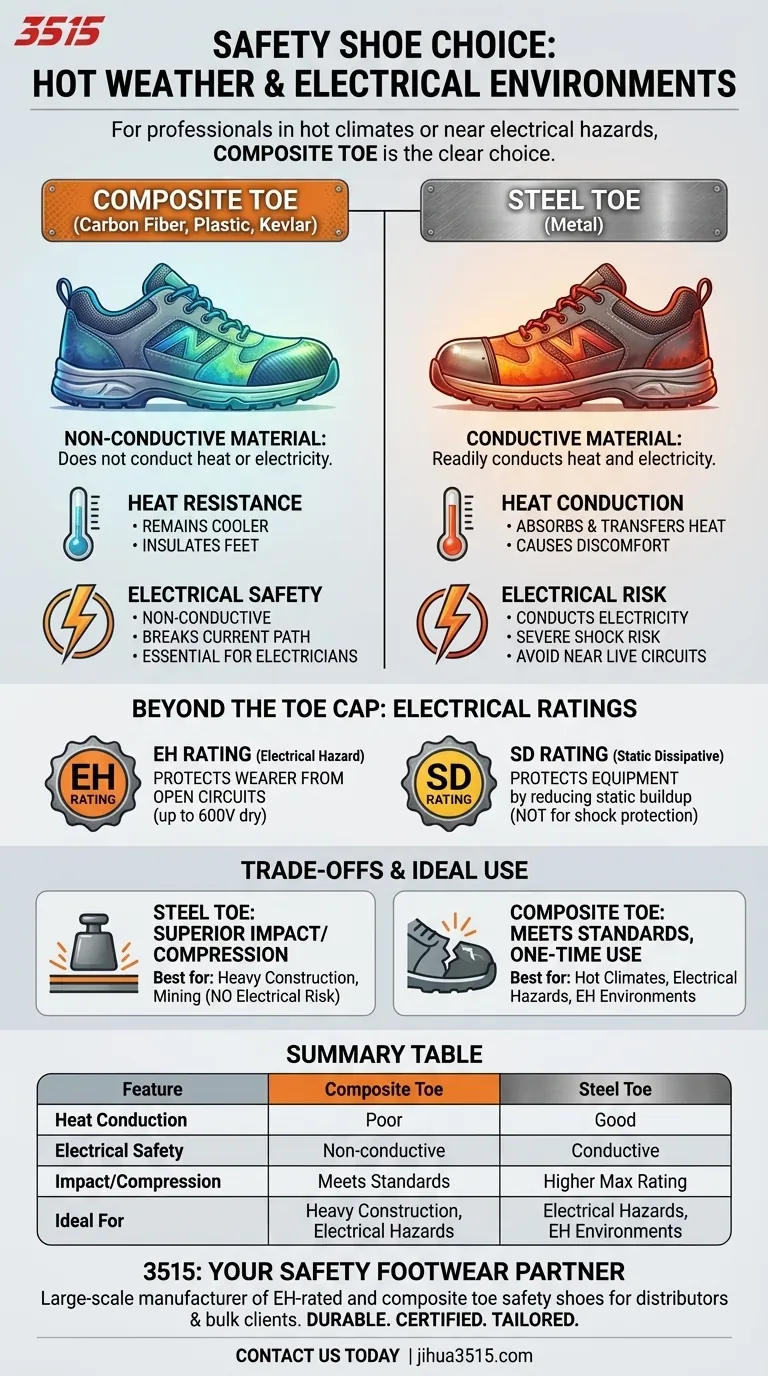

For professionals working in hot climates or near electrical hazards, the clear choice is a safety shoe with a composite toe. Unlike steel, the materials used in composite toes—such as carbon fiber, plastic, or Kevlar—do not conduct heat or electricity, providing a fundamental layer of protection against these specific environmental risks.

The decision between composite and steel extends beyond the toe cap; it's about matching the material's intrinsic properties and the shoe's official safety rating to the primary hazards of your work environment.

Why Material Choice Matters for Environmental Hazards

The material of your safety toe cap directly influences your comfort and safety when dealing with extreme temperatures or electrical currents.

Superiority in Hot Weather

A steel toe cap is a thermal conductor. In hot environments, it will absorb ambient heat and transfer it directly to your feet, creating significant discomfort.

Composite materials are poor conductors of heat. This insulating property means they remain at a more stable temperature, keeping your feet significantly cooler and more comfortable during a long workday in the heat.

The Critical Non-Conductive Advantage

The most significant difference is in electrical conductivity. Steel readily conducts electricity, posing a severe risk if you come into contact with a live circuit.

Composite materials are non-conductive. This makes them an essential safety feature for electricians or anyone working in an environment with electrical hazards, as they help to break the path of a dangerous electrical current.

Beyond the Toe Cap: Understanding Electrical Safety Ratings

While a composite toe is a critical component, it is not the only feature that makes a shoe safe for electrical work. You must look for a specific, official rating.

The Role of the EH Rating

A boot labeled with an Electrical Hazard (EH) rating is designed and tested to protect the wearer from open circuits of up to 600 volts under dry conditions.

This rating, certified by ASTM International, applies to the entire construction of the shoe, particularly the outsole, and confirms it is made from non-conductive materials that will impede the flow of electricity.

Static Dissipative (SD) vs. EH

It is crucial not to confuse EH-rated shoes with Static Dissipative (SD) footwear.

SD shoes are designed to reduce the buildup of static electricity by conducting it safely to the ground. They are used to protect sensitive electronic equipment, not to protect the wearer from electric shock.

Holistic Features for Electrical Work

A true electrical safety shoe combines several key elements. In addition to the EH rating and composite toe, these boots typically feature heavily insulated materials and robust, slip-resistant outsoles to ensure stable footing.

Understanding the Trade-offs

Choosing the right safety shoe involves balancing different protective features. While composite toes are superior for thermal and electrical resistance, steel toes still have a place.

The Case for Steel Toe

Steel toe caps often provide superior protection against extreme impact and compression. In environments with a very high risk of crushing injuries from exceptionally heavy objects, such as in heavy construction or mining, a steel toe may offer a higher level of absolute protection.

Composite Toe Limitations

While they meet or exceed ASTM safety standards, composite toes may not carry the absolute highest impact ratings found in some specialized steel-toe models. Furthermore, after a single significant impact, the integrity of a composite toe is compromised, and the shoe must be replaced immediately.

Making the Right Choice for Your Environment

Your specific workplace hazards should always dictate your choice in personal protective equipment.

- If your primary focus is working around live electrical hazards: You must select a boot with an official EH rating and a composite toe to ensure non-conductive protection.

- If your primary focus is comfort and safety in hot weather: A composite toe shoe is the superior choice, as it will not transfer external heat to your feet.

- If your primary focus is maximum protection from crushing and impact: A steel-toe boot may be the better option, as long as electrical and thermal hazards are not your main concern.

Ultimately, selecting the correct safety shoe is a critical decision that directly impacts your well-being on the job.

Summary Table:

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Heat Conduction | Poor conductor, keeps feet cool | Good conductor, can transfer heat |

| Electrical Safety | Non-conductive (safer for electrical work) | Conductive (risk of shock) |

| Impact/Compression | Meets ASTM standards, but may have lower max ratings | Often higher maximum protection ratings |

| Ideal For | Hot climates, electrical hazards, EH-rated environments | Heavy impact/crushing hazards (no electrical risk) |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated and composite toe safety shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, certified footwear tailored to hot weather and electrical work environments.

Contact us today to discuss your safety shoe needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do slip resistant safety shoes differ from non-slip rated shoes? Cut Through the Marketing Jargon

- What are some specialized features available in modern safety shoes beyond toe protection? Enhanced Workplace Safety

- How do insulated safety shoes reduce the risk of electric shock in welding? Essential Electrical Protection Explained

- How does breathable industrial dust-proof equipment protect against silicosis? Advanced Safety for Mining & Construction

- What is the importance of professional rubber safety boots for skin protection? Ensure High-Level Agricultural Safety

- Why are protective toe boots required on job sites? To Prevent Severe Foot Injuries from Impact & Compression

- What role does professional footwear play in protecting workers? Enhance Stability During Trunk Rotation and Bending

- Why is impact and puncture resistance a critical feature for fishing footwear? Protect Your Crew from Deck Hazards