Polyvinyl Chloride (PVC) offers the superior chemical defense profile when compared to rubber or neoprene alternatives. It provides the broadest resistance against oils, animal fats, and industrial agents, making it the definitive choice for preventing skin irritation and chemical burns in hazardous environments.

While rubber is physically tougher, PVC is the primary barrier against hazardous liquids. If your work environment involves consistent exposure to greases, fats, or corrosive agents, PVC is the standard for chemical safety, preventing harm where other materials might degrade or allow permeation.

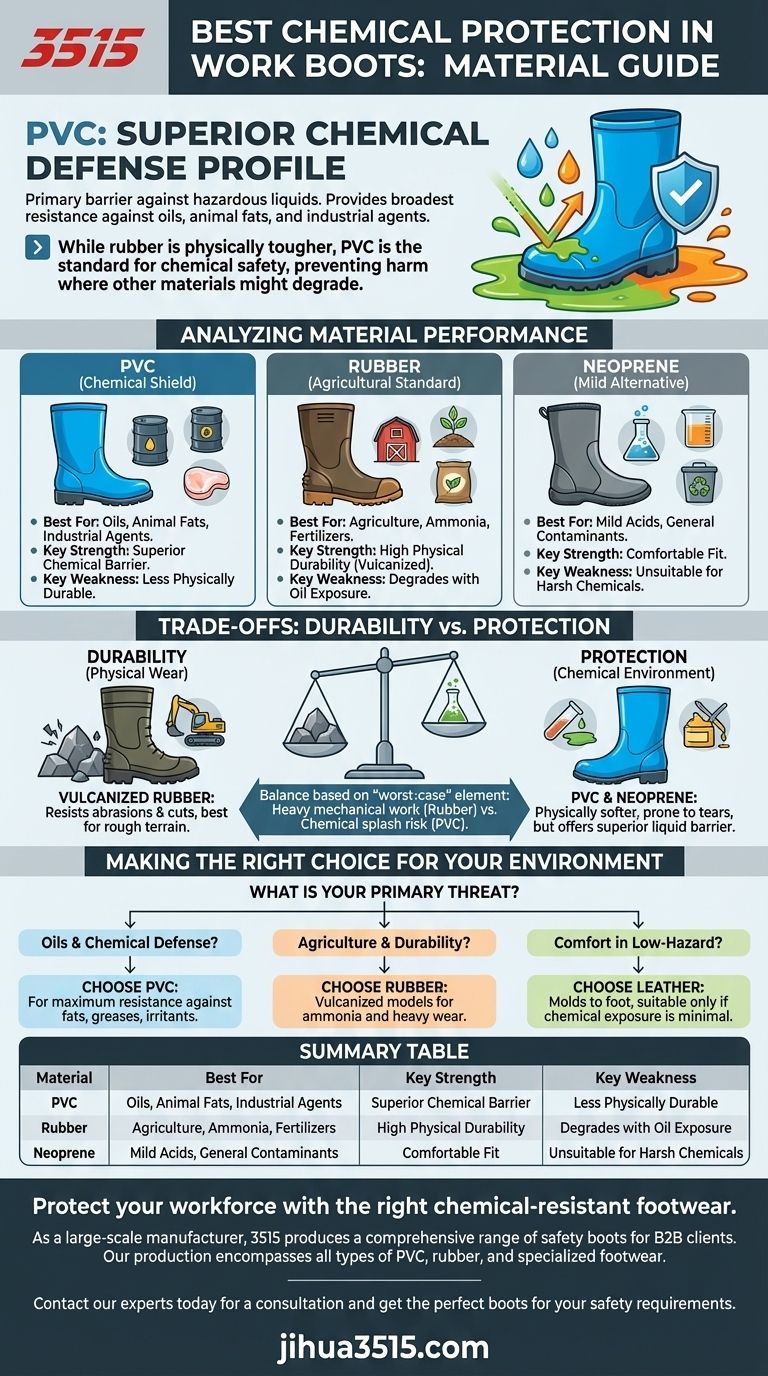

Analyzing Material Performance

To select the correct boot, you must match the material's specific resistance profile to the contaminants in your workspace.

The Chemical Shield: PVC

PVC is chemically inert to a wide range of industrial substances. It is particularly effective against oils and animal fats, which often cause other polymers to swell or disintegrate.

This material creates a reliable barrier that prevents liquids from reaching the skin. It is the optimal choice for environments where chemical splashes or standing grease are the primary risks.

The Agricultural Standard: Rubber

Rubber fills a specific niche in chemical resistance, particularly in agricultural settings. It offers excellent protection against ammonia, animal waste, and fertilizers.

However, it has a critical weakness: certain oils. Exposure to industrial oils or heavy fats can cause rubber to degrade rapidly, compromising the boot's integrity.

The Mild Alternative: Neoprene

Neoprene serves as a middle ground for less hazardous environments. It offers decent resistance to mild acids and general contaminants.

It is not suitable for harsh industrial substances. If you are dealing with concentrated chemicals or heavy greases, neoprene will not offer sufficient protection compared to PVC.

Understanding the Trade-offs: Durability vs. Protection

Choosing the "best" boot often requires balancing chemical resistance against physical durability. The material that stops chemicals best is not always the one that lasts the longest under physical stress.

The Durability of Rubber

When physical wear and tear is the main concern, rubber is the superior material. It is highly resistant to abrasions and cuts.

Vulcanized rubber offers reinforced strength, making it the most durable option for rough terrain or heavy mechanical work. However, you sacrifice broad-spectrum oil resistance for this physical toughness.

The Vulnerability of PVC and Neoprene

While PVC is the leader in chemical protection, it is physically softer than vulcanized rubber. Both PVC and neoprene are more prone to tears, snags, and physical damage.

These materials are best suited for "less demanding" physical conditions where the main threat is the liquid environment, rather than jagged rocks or heavy machinery.

General Construction vs. Chemical Safety

Leather is often cited as the "best" general work boot material because it is durable and molds to the foot for a custom fit. However, leather is porous and organic.

For strict chemical protection, leather is generally inferior to synthetic barriers like PVC. While Nylon boots offer breathability and light weight, they lack the durability required for hazardous industrial zones.

Making the Right Choice for Your Environment

Select your material based on the specific "worst-case" element you encounter daily.

- If your primary focus is Oil and Chemical Defense: Choose PVC to ensure maximum resistance against fats, greases, and skin irritants.

- If your primary focus is Agriculture and Durability: Choose Rubber, particularly vulcanized models, to withstand ammonia and heavy physical wear.

- If your primary focus is Comfort in Low-Hazard Zones: Choose Leather for its ability to mold to the foot, provided chemical exposure is minimal.

Prioritize the material that defends against your specific environmental threat, rather than seeking a one-size-fits-all solution.

Summary Table:

| Material | Best For | Key Strength | Key Weakness |

|---|---|---|---|

| PVC | Oils, Animal Fats, Industrial Agents | Superior Chemical Barrier | Less Physically Durable |

| Rubber | Agriculture, Ammonia, Fertilizers | High Physical Durability | Degrades with Oil Exposure |

| Neoprene | Mild Acids, General Contaminants | Comfortable Fit | Unsuitable for Harsh Chemicals |

Protect your workforce with the right chemical-resistant footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of PVC, rubber, and specialized footwear designed to meet the specific hazards of your work environment.

We ensure your team has the reliable protection they need. Contact our experts today for a consultation and get the perfect boots for your safety requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How should work boots be maintained to prolong their lifespan? Essential Care for Long-Lasting Safety

- Is the toe box a critical component of boot fit? Focus on the 3 pillars for a perfect fit.

- Why are wildfire boots essential protective equipment? The Critical Role of Specialized Footwear

- Are oil-resistant boots also waterproof? Don't Confuse These Two Critical Safety Features

- How do manufacturers ensure a secure fit in light work boots? Discover the Engineering Behind Perfect Fit

- How should women's work boots be cared for and maintained? Extend Boot Life & Protect Your Feet

- What work boot features are essential for farming and agricultural work? Complete Protection Guide

- How do the heels differ between cowboy boots and Western work boots? Choose the Right Heel for Your Job