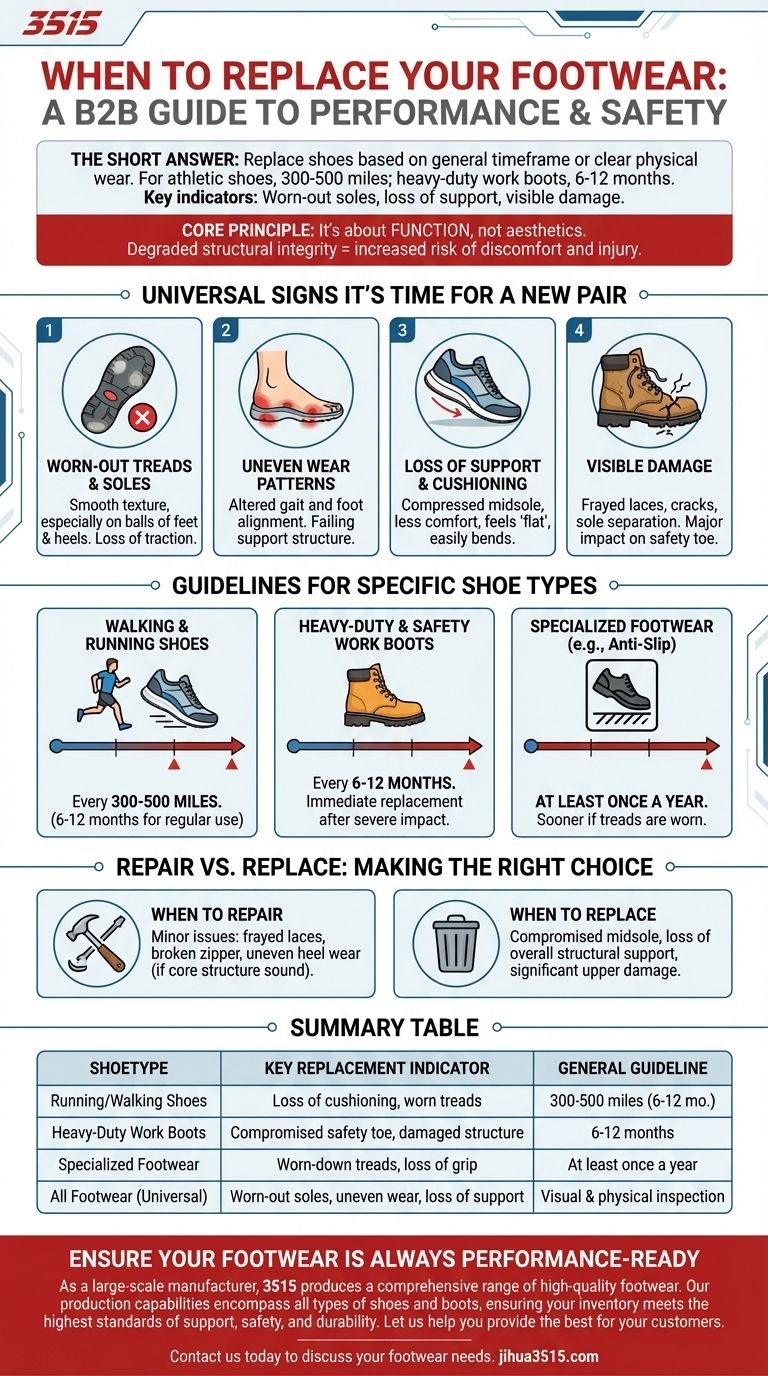

The short answer is you should replace shoes based on either a general timeframe or, more importantly, when they show clear signs of physical wear. For athletic shoes, this is often every 300-500 miles, while heavy-duty work boots may last 6 to 12 months. For all footwear, the most reliable indicators are worn-out soles, loss of support, and visible damage.

The core principle of shoe replacement is not about aesthetics, but about function. A shoe's primary job is to provide support and protection; you replace it when its structural integrity has degraded to the point where it can no longer do that job effectively, increasing your risk of discomfort and injury.

The "Why" Behind Replacement: It's About Degraded Performance

A shoe is a piece of functional equipment. Over time, the materials that provide cushioning, stability, and traction break down through repeated stress and impact.

Continuing to use a worn-out shoe means you are no longer getting the support it was designed to provide. This can lead to rubbing, irritation, and an increased risk of injury.

Universal Signs It's Time for a New Pair

Regardless of the shoe type, certain physical indicators signal that a replacement is necessary. Regular inspection is the most effective way to gauge the lifespan of your footwear.

Worn-Out Treads and Soles

The most obvious sign is the bottom of the shoe. Look for a smooth, worn-down texture, especially around the balls of your feet and the heels. For anti-slip or specialized shoes, any significant loss of tread means a loss of traction and safety.

Uneven Wear Patterns

If the sole is wearing down unevenly, it can alter your gait and foot alignment. This is a clear sign that the shoe's support structure is failing and should be replaced.

Loss of Support and Cushioning

The midsole is the cushioning layer between the sole and your foot. When it compresses and fails, the shoe will feel less comfortable and supportive. If the shoe feels "flat" or you can easily bend it in half with little resistance, the support is gone.

Visible Damage

Obvious damage is a clear indicator. This includes frayed laces or malfunctioning zippers, but also any cracks in the upper material or separation between the sole and the rest of the shoe. For safety boots, any major impact to the safety toe compromises its integrity, requiring immediate replacement.

Guidelines for Specific Shoe Types

While visual inspection is key, different shoe categories have established mileage or time-based replacement guidelines.

Walking and Running Shoes

These shoes are designed for performance and take a consistent pounding. Experts recommend replacing them every 300 to 500 miles. For someone walking 30 minutes a day, five days a week, this translates to a new pair every 6 to 12 months.

Heavy-Duty and Safety Work Boots

Due to intense use and harsh environments, work boots have a shorter lifespan. They should typically be replaced every 6 to 12 months. Any boot that has sustained a severe impact or has a compromised safety feature must be replaced immediately, regardless of its age.

Specialized Footwear (e.g., Anti-Slip)

The performance of specialized shoes is directly tied to safety. Anti-slip shoes, for example, should be replaced at least once a year, or sooner if regular inspections show the tread is wearing down.

Understanding the Trade-offs: Repair vs. Replace

Not all wear requires a full replacement. Understanding the difference is key to maximizing the life of your footwear without compromising safety or comfort.

When to Repair

Minor issues can often be addressed by a professional cobbler. This includes replacing frayed laces, fixing a broken zipper, or having heels or soles professionally repaired if they are worn unevenly but the shoe's core structure is still sound.

When to Replace

Repairs cannot fix a compromised midsole or a loss of overall structural support. If the shoe's cushioning is dead or the upper is significantly damaged, a full replacement is the only safe and effective option. You cannot repair a loss of fundamental support.

Making the Right Choice for Your Footwear

Use these guidelines to determine your replacement schedule based on your primary use case.

- If your primary focus is athletic performance: Prioritize mileage (300-500 miles) and the feel of the shoe's cushioning over its visual appearance.

- If your primary focus is workplace safety: Adhere to time-based guidelines (6-12 months for boots) and perform frequent inspections for damage.

- If your primary focus is casual, everyday comfort: Rely on visible indicators like worn-out soles and a noticeable decrease in comfort and support.

Ultimately, proactively inspecting your footwear is the best strategy for ensuring comfort, performance, and safety.

Summary Table:

| Shoe Type | Key Replacement Indicator | General Guideline |

|---|---|---|

| Running/Walking Shoes | Loss of cushioning, worn treads | Every 300-500 miles (6-12 months) |

| Heavy-Duty Work Boots | Compromised safety toe, damaged structure | Every 6-12 months |

| Specialized Footwear (e.g., Anti-Slip) | Worn-down treads, loss of grip | At least once a year |

| All Footwear (Universal Signs) | Worn-out soles, uneven wear, loss of support | Based on visual and physical inspection |

Ensure Your Footwear is Always Performance-Ready

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from durable safety work boots to high-performance athletic footwear, ensuring your inventory meets the highest standards of support, safety, and durability.

Let us help you provide the best for your customers.

Contact us today to discuss your footwear needs and discover how our manufacturing expertise can benefit your business.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Lightweight Cushioned Athletic Sneakers for Custom Bulk Production

- Wholesale Durable & Breathable Training Shoes for Custom Brands

People Also Ask

- How does the provision of industrial-grade PPE improve construction operational efficiency? Boost Project Continuity

- How does testing on stairs with varied dimensions guide footwear development? Enhance Safety Through Biomechanics

- Why is industrial-grade heat pressing equipment preferred over traditional bonding? Unlock Superior Footwear Performance

- What is the primary role of a high-performance dual-core microcontroller in smart obstacle-avoidance footwear?

- How do smart medical tools contribute to the diversity of data within a health-integrated footwear ecosystem?

- What role does a high-frame-rate 3D motion capture system play in gait analysis? Precision Data for Footwear Testing

- How does the mirror software function improve production efficiency in automated shoe polishing? Halve Setup Time Now

- What are the technical and manufacturing advantages of using natural leather? Engineered Comfort & Precision