Damaged work shoes must be taken out of service immediately when they show any signs of structural failure that compromise their protective capabilities. This includes visible cracks in the upper material, excessively worn or separated soles, or any damage that would allow workplace hazards like hot liquids or sharp objects to penetrate the shoe.

The decision to replace work shoes is not about aesthetics; it is a critical risk assessment. Any damage that undermines the shoe's fundamental ability to protect you from impact, puncture, electrical shock, or slips means it has failed as a piece of personal protective equipment (PPE).

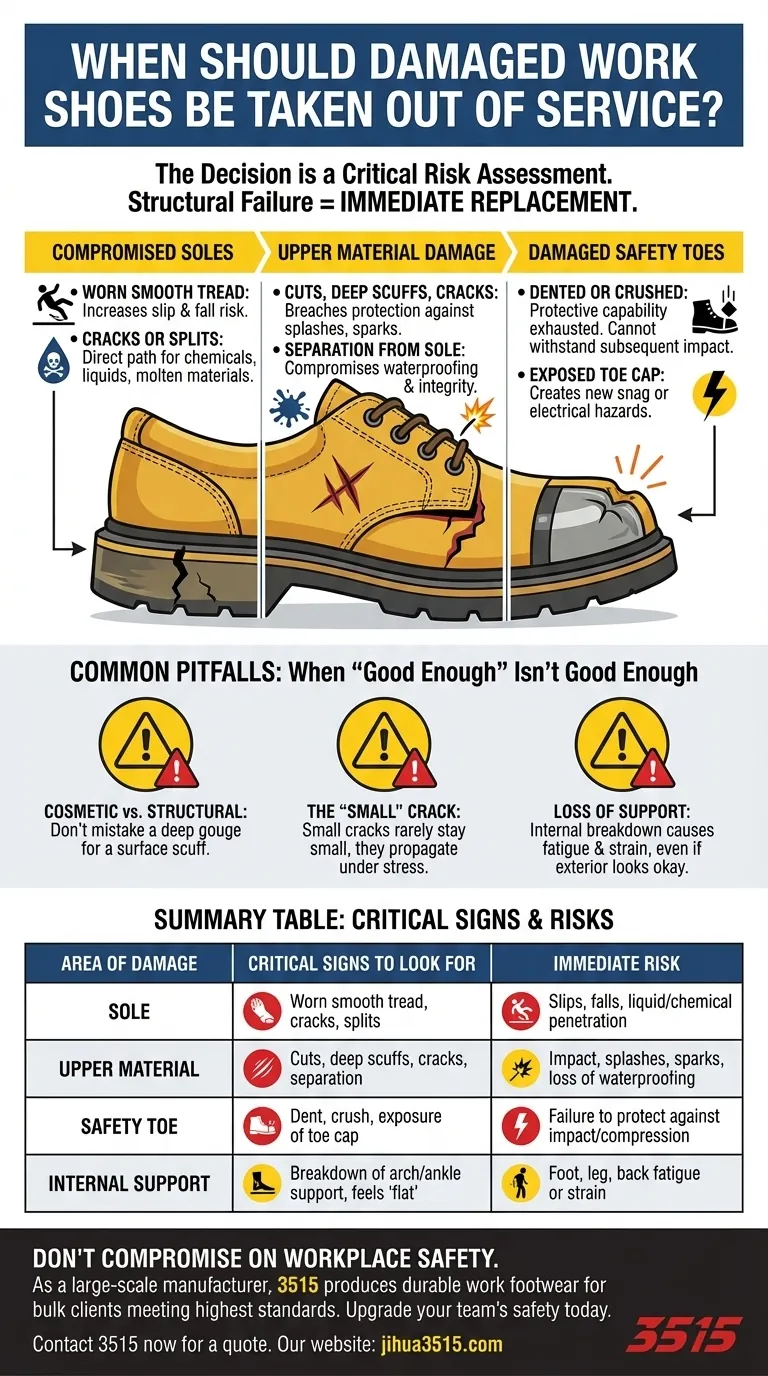

The Anatomy of Failure: Key Areas to Inspect

Understanding why specific types of damage are critical helps in making consistent and safe decisions. A thorough inspection should be a regular habit, focusing on the key components responsible for your safety.

Compromised Soles: The First Line of Defense

The sole of a work shoe provides traction, puncture resistance, and a barrier from ground-based hazards.

When the tread is worn smooth, the shoe loses its ability to grip surfaces, dramatically increasing the risk of slips and falls, especially on wet or oily floors.

Cracks or splits in the sole completely negate its protective value against liquids. This damage creates a direct path for chemicals, water, or even molten materials to reach your foot.

Upper Material Damage: Breaching the Shield

The "upper" is the material that covers the top of your foot. Its integrity is crucial for protection against splashes, sparks, and impacts.

Any cuts, deep scuffs, or cracks in the leather or synthetic upper are a serious concern. A breach in this layer, as noted in safety guidelines, can allow hazards like hot metal splashes to seep into the shoe, causing severe burns.

Look for separation between the upper and the sole. This common point of failure immediately compromises the shoe's waterproofness and structural integrity.

Damaged Safety Toes: A Hidden Danger

The safety toe (steel, composite, or alloy) is designed to withstand a single, significant impact.

If a shoe has sustained an impact that has dented or crushed the safety toe, its protective capability is exhausted. It will not provide the specified protection against a subsequent impact and must be replaced immediately.

Similarly, if wear and tear have exposed the safety toe cap, the shoe is no longer safe. This can create a new snag or electrical conductivity hazard, depending on the material.

Common Pitfalls: When "Good Enough" Isn't Good Enough

Objectivity is essential when inspecting PPE. Familiarity with a pair of comfortable boots can lead to overlooking serious, developing safety issues.

Mistaking Cosmetic Wear for Minor Damage

Scuffs on the surface are normal. However, you must be able to distinguish between a surface scuff and a deep gouge or crack that has penetrated the primary material. One is cosmetic; the other is a structural failure.

Ignoring a Single "Small" Crack

A small crack in a sole or upper rarely stays small. Under the daily stress of walking and flexing, it will quickly propagate, expanding until the shoe's protective barrier is completely compromised.

Overlooking the Loss of Support

Work shoes also provide crucial arch and ankle support. Over time, the internal structure breaks down, even if the exterior looks acceptable. If the shoe feels "flat" and no longer provides support, it can contribute to foot, leg, and back fatigue and long-term strain.

Making the Right Choice for Your Goal

Your specific work environment dictates which signs of wear are the most critical. Use this framework to guide your inspection and replacement policy.

- If your primary focus is preventing slips, trips, and falls: Immediately replace shoes when the sole's tread pattern is no longer distinct or deep.

- If your primary focus is protection from impact and compression: Any dent, deformation, or exposure of the safety toe cap means the shoes must be taken out of service.

- If your primary focus is guarding against chemical or liquid hazards: The smallest crack, split, or seam separation is grounds for immediate replacement.

Treating your work footwear as critical safety equipment, not just apparel, is the foundation of a secure work environment.

Summary Table:

| Area of Damage | Critical Signs to Look For | Immediate Risk |

|---|---|---|

| Sole | Worn smooth tread, cracks, or splits | Slips, falls, liquid/chemical penetration |

| Upper Material | Cuts, deep scuffs, cracks, or separation from sole | Impact, splashes, sparks, loss of waterproofing |

| Safety Toe | Dent, crush, or exposure of the toe cap | Failure to protect against impact or compression |

| Internal Support | Breakdown of arch/ankle support, feels 'flat' | Foot, leg, and back fatigue or strain |

Don't Compromise on Workplace Safety

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and reliable work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to meet the highest protection standards.

Upgrade your team's safety today. Ensure your workforce is equipped with PPE that won't let them down.

Contact 3515 now for a quote and discover how our footwear solutions can protect your most valuable asset—your people.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management