The short answer is clear: Protective or work shoes are more suitable than safety shoes when your environment does not have a significant risk of heavy falling or crushing objects impacting the toes. While all three categories can offer features like slip resistance, the fundamental difference lies in the level of impact protection for the forefoot.

Your goal is not to choose the "safest" shoe in absolute terms, but the "right" shoe for your specific, assessed risks. Mandating the highest level of protection where it isn't needed can introduce unnecessary cost, weight, and discomfort without a corresponding safety benefit.

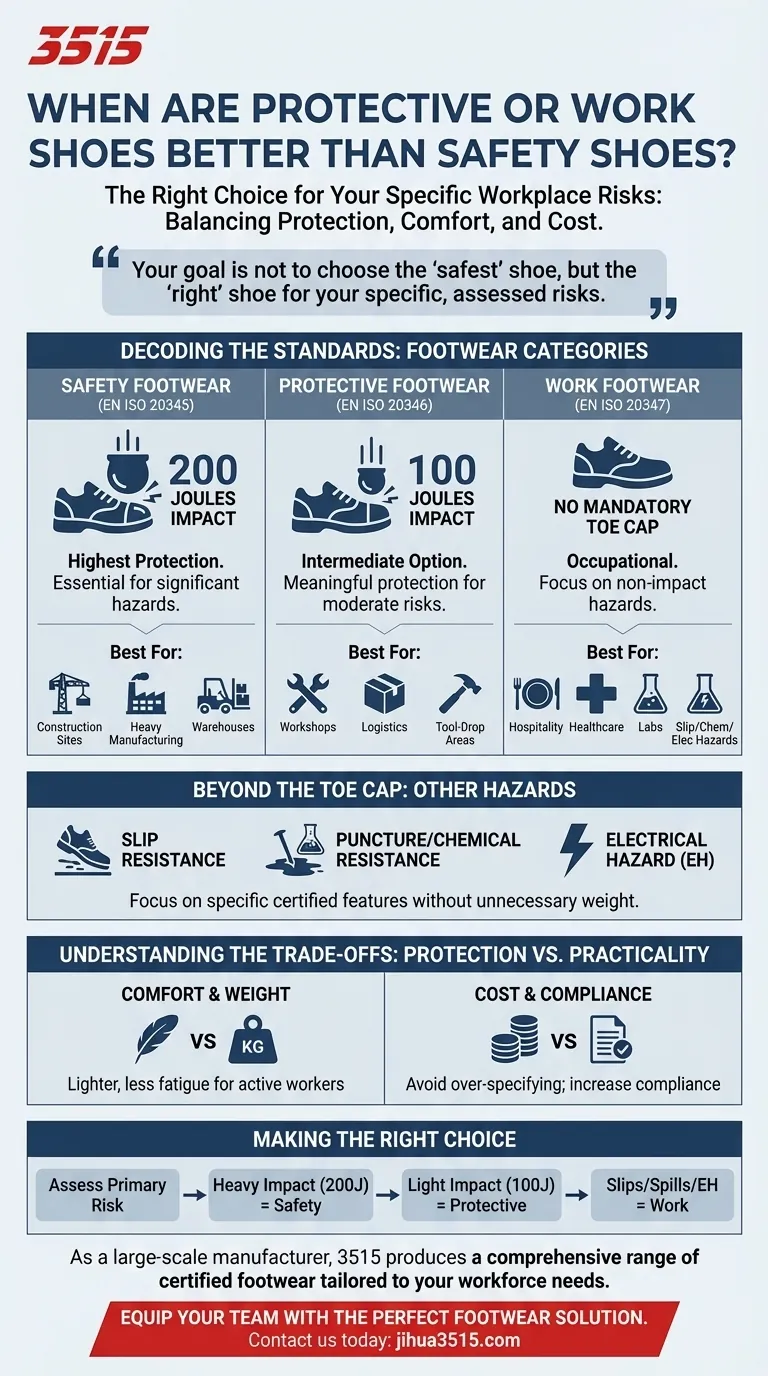

Decoding the Standards: Safety, Protective, and Work Footwear

The choice between these footwear categories comes down to a formal risk assessment of your work environment. International standards (like EN ISO) provide a clear framework based on the level of impact resistance the toe cap can withstand, measured in joules.

Safety Footwear (EN ISO 20345): The Highest Standard

This is the category most people think of as "steel-toe boots." They are equipped with a toe cap tested to withstand 200 joules of impact.

This level of protection is non-negotiable in environments with significant hazards from falling objects, such as construction sites, manufacturing plants, and warehouses with heavy materials.

Protective Footwear (EN ISO 20346): The Intermediate Option

Protective footwear features a toe cap that withstands 100 joules of impact. This provides a meaningful level of protection against moderate risks.

This is a suitable choice in workshops or logistics roles where someone might drop a heavy tool or a small part, but the risk of being crushed by heavy machinery or materials is negligible.

Work Footwear (EN ISO 20347): Protection Without the Toe Cap

Often called occupational footwear, these shoes have no mandatory toe cap protection. This does not mean they offer no protection at all.

Work shoes are ideal for jobs where the primary hazards are not impact-related. They are often specialized for other risks, such as slips, chemical exposure, or electrical shock.

Beyond the Toe Cap: Assessing Other Workplace Hazards

The decision to forgo a safety toe cap allows you to focus on features that address more probable risks in certain professions. A shoe can lack a toe cap but still be a highly specialized and essential piece of protective equipment.

Slip Resistance

For workers in hospitality, healthcare, or food service, the risk of a slip-and-fall on a wet floor is far greater than the risk of an object crushing their foot. A work shoe with a superior slip-resistant sole is the correct choice here.

Puncture and Chemical Resistance

In fields like waste management or laboratory work, protection from sharp objects underfoot or corrosive spills is the top priority. A puncture-resistant midsole or chemically resistant upper material is critical, regardless of the toe cap rating.

Electrical Hazard (EH) Protection

For electricians and maintenance workers, a shoe rated for Electrical Hazard (EH) protection is essential to prevent shock. These specialized features can be found in work, protective, and safety footwear categories.

Understanding the Trade-offs: Protection vs. Practicality

Choosing footwear based on a proper risk assessment, rather than simply defaulting to the highest standard, has significant practical benefits.

Comfort and Weight

Safety toe caps, whether steel or composite, add weight and rigidity to a shoe. Over an eight-hour shift, this extra weight contributes to fatigue. For active workers, a lighter work or protective shoe can dramatically improve comfort and reduce strain.

Cost and Compliance

Generally, footwear with higher-rated safety features comes at a higher price. Over-specifying footwear for an entire workforce can lead to significant unnecessary costs. Furthermore, if employees find the mandated shoes unnecessarily heavy or uncomfortable, they may be less likely to wear them consistently, defeating the purpose of the program.

Making the Right Choice for Your Environment

Your final decision should be guided by a formal hazard analysis of the specific tasks your employees perform.

- If your primary risk is heavy impact or compression: Mandate certified Safety Footwear (200 joules). This is the only acceptable choice for construction, heavy industry, and similar environments.

- If your primary risk is light impact from dropped tools or parts: Consider Protective Footwear (100 joules) to provide adequate protection with improved comfort and lower cost.

- If your primary risks are slips, spills, or electrical hazards: Focus on Work Footwear that has the specific certified features you need, such as superior slip resistance or an EH rating, without the unnecessary weight of a toe cap.

By matching the footwear precisely to the hazard, you create a safer, more comfortable, and more efficient work environment.

Summary Table:

| Footwear Type | Standard | Toe Cap Impact Protection | Best For Environments |

|---|---|---|---|

| Safety Footwear | EN ISO 20345 | 200 Joules | Construction, heavy manufacturing, warehouses with heavy materials |

| Protective Footwear | EN ISO 20346 | 100 Joules | Workshops, logistics, areas with moderate tool-drop risks |

| Work Footwear | EN ISO 20347 | No toe cap | Hospitality, healthcare, labs, where slip/chemical/electrical hazards are primary |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified footwear for distributors, brand owners, and bulk clients. We understand that the right footwear balances protection, comfort, and cost-effectiveness. Our production capabilities encompass all types of safety, protective, and work shoes and boots, tailored to your specific hazard assessments and workforce needs.

Let us help you equip your team with the perfect footwear solution. Contact us today to discuss your requirements and discover how our expertise can enhance your workplace safety program.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How can material selection mitigate skin injuries caused by the physical pressure of protective equipment? Key Strategies

- Why might mobile workers prefer composite toe boots? Lighter, Safer, and More Comfortable for All-Day Wear

- What roles do 3D vision systems and industrial robots play in the manufacturing of fire safety boots? Smart Automation

- What is the ASTM F2413 Standard for protective toe boots? Ensure OSHA-Compliant Foot Safety

- What are the characteristics of a steel toe in oil-resistant safety boots? Maximum Crush Protection

- What are the main safety features of S1-S5 shoes? The 3 Essential Protections Explained

- How do professional-grade safety shoes contribute to accident prevention? Reduce Risk with Advanced PPE Footwear

- Why is it important to balance cost and durability when purchasing safety boots? Maximize Long-Term Value