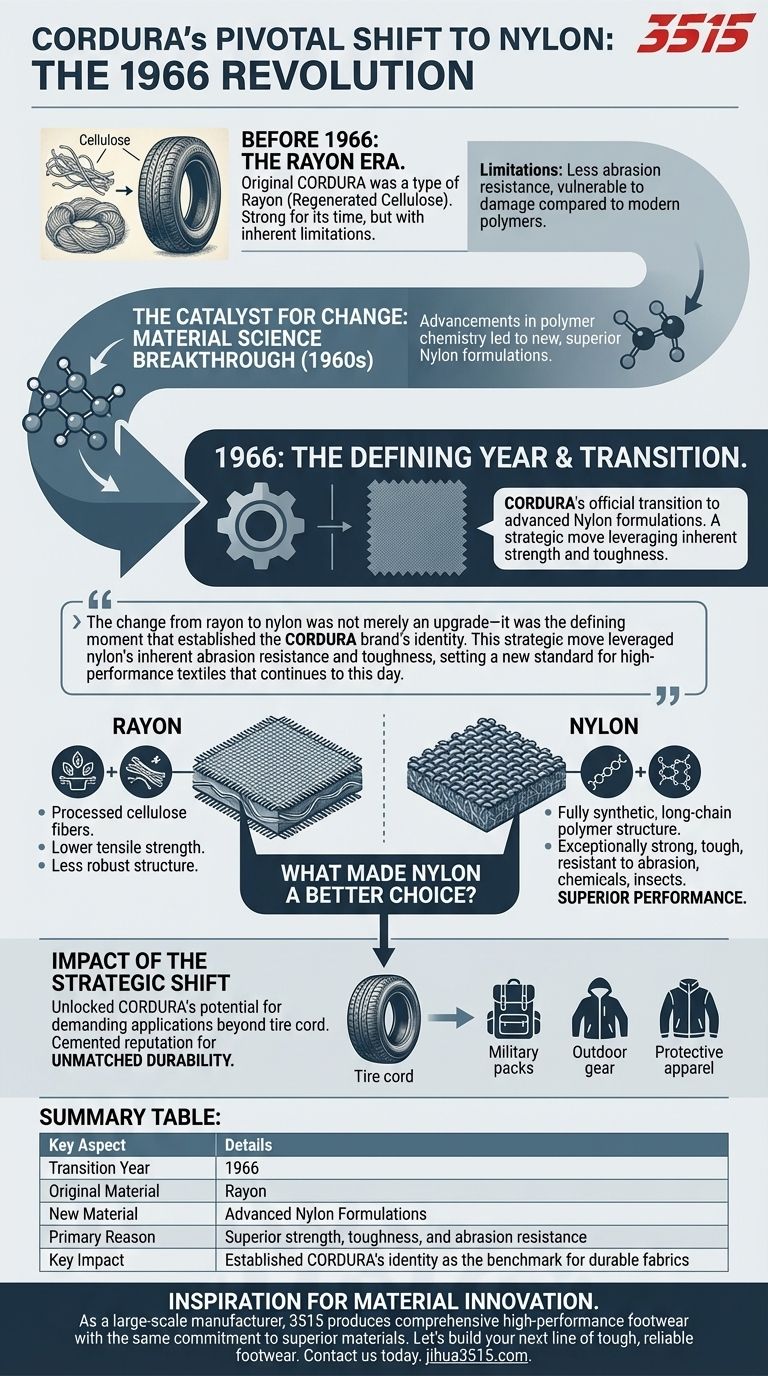

CORDURA's pivotal shift to nylon occurred in 1966. This transition was driven by a fundamental leap in material science; newly developed formulations of nylon were proven to be vastly superior in strength and durability compared to the fabric's original rayon composition.

The change from rayon to nylon was not merely an upgrade—it was the defining moment that established the CORDURA brand's identity. This strategic move leveraged nylon's inherent abrasion resistance and toughness, setting a new standard for high-performance textiles that continues to this day.

The Genesis of CORDURA: A Material Evolution

To understand the importance of this change, we must first look at the material CORDURA started with and the technological breakthrough that prompted the switch.

The Original Material: Rayon

CORDURA was initially developed by DuPont as a type of rayon, a fiber derived from regenerated cellulose. While strong for its time, rayon had inherent limitations, particularly when compared to the synthetic polymers that were emerging.

The Catalyst for Change: Nylon's Breakthrough

The 1960s saw significant advancements in polymer chemistry. New formulations of nylon, a fully synthetic polymer, demonstrated properties that were a dramatic improvement over existing fibers.

This new material offered a level of tensile strength and abrasion resistance that rayon simply could not match, making it the clear choice for demanding applications.

The Defining Year: 1966

Recognizing this technological advantage, the brand officially transitioned the CORDURA product line to these superior nylon formulations in 1966. This single decision charted the course for the brand's future.

Understanding the Material Superiority

The term "superior" isn't just marketing; it reflects fundamental differences in the materials' molecular structure and resulting physical properties.

What Made Nylon a Better Choice?

Nylon fibers are exceptionally strong, tough, and resistant to damage from abrasion, insects, and chemicals. Its long-chain polymer structure is inherently more robust than the processed cellulose fibers of rayon.

This meant that products made with nylon CORDURA could withstand far more punishment, last significantly longer, and perform more reliably in harsh conditions.

From Tire Cord to Tactical Gear

Originally engineered for use in tires, CORDURA's transition to nylon unlocked its potential for a much broader set of applications.

The unmatched durability made it the ideal material for products where failure was not an option, such as military packs, outdoor gear, and protective apparel—the markets it dominates today.

The Impact of This Strategic Shift

This was more than a simple material substitution; it was a strategic pivot that had a lasting impact on the entire textile industry.

Why Not Start with Nylon?

The specific nylon formulations that gave CORDURA its legendary toughness were simply not available or perfected when the brand was first conceived. The 1966 transition was a direct result of innovation making a better material commercially viable.

The Legacy of the 1966 Transition

By embracing the best available material science, CORDURA cemented its reputation. The brand became synonymous with durability because of its early and decisive commitment to high-performance nylon. This move set a benchmark for rugged textiles that competitors have chased for decades.

What This Means for Material Selection

The history of CORDURA's transition offers a clear lesson in how material choice dictates performance and defines a product's value.

- If your primary focus is maximum durability: The CORDURA story proves that the base polymer, in this case nylon, is the true foundation of a fabric's performance characteristics.

- If you are evaluating a brand's reputation: Look for pivotal technical decisions in its history, as the 1966 shift demonstrates how a commitment to superior materials creates a lasting legacy of trust.

Ultimately, CORDURA's transition to nylon is a powerful example of how embracing material innovation is the key to creating a legacy of unparalleled performance.

Summary Table:

| Key Aspect | Details |

|---|---|

| Transition Year | 1966 |

| Original Material | Rayon |

| New Material | Advanced Nylon Formulations |

| Primary Reason | Superior strength, toughness, and abrasion resistance |

| Key Impact | Established CORDURA's identity as the benchmark for durable fabrics |

Inspired by CORDURA's legacy of material innovation?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable shoes and boots, built with the same commitment to superior materials and construction that defines leading brands.

Let's build your next line of tough, reliable footwear. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Classic Leather Derby Dress Shoes Wholesale & Custom Manufacturing

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What is the function of industrial-grade 3D-printed nylon materials in smart footwear sensor protection?

- Why is the integration of industrial-grade high-frame-rate cameras necessary? Enhance Footwear Biomechanical Accuracy

- What are the advantages and disadvantages of cotton as a liner material? Choose the Right Liner for Comfort or Performance

- How does the body respond to extreme cold temperatures? The Vital Survival Strategy Explained

- What is the function of a digital barometer in wearable systems? Master 3D Tracking for Emergency Personnel

- How do conductive threads and conductive tape work together? Durable Connectivity for Flexible Wearable Sensors

- What is the specific impact of footwear weight on energy metabolic cost? Boost Efficiency with Lightweight Design

- Why is shaft height important in motorcycle boots? A Critical Factor for Rider Safety