At their core, cold-weather boots achieve waterproofing through a multi-layered defense system. The primary features are an internal waterproof membrane or liner, an outer shell made of impermeable materials like rubber or treated leather, and sealed seam construction that prevents water from leaking through the stitching.

True waterproofing in a winter boot is not about a single feature, but a combination of materials and construction. The critical challenge is balancing this protection against the inevitable trade-offs in breathability, weight, and cost.

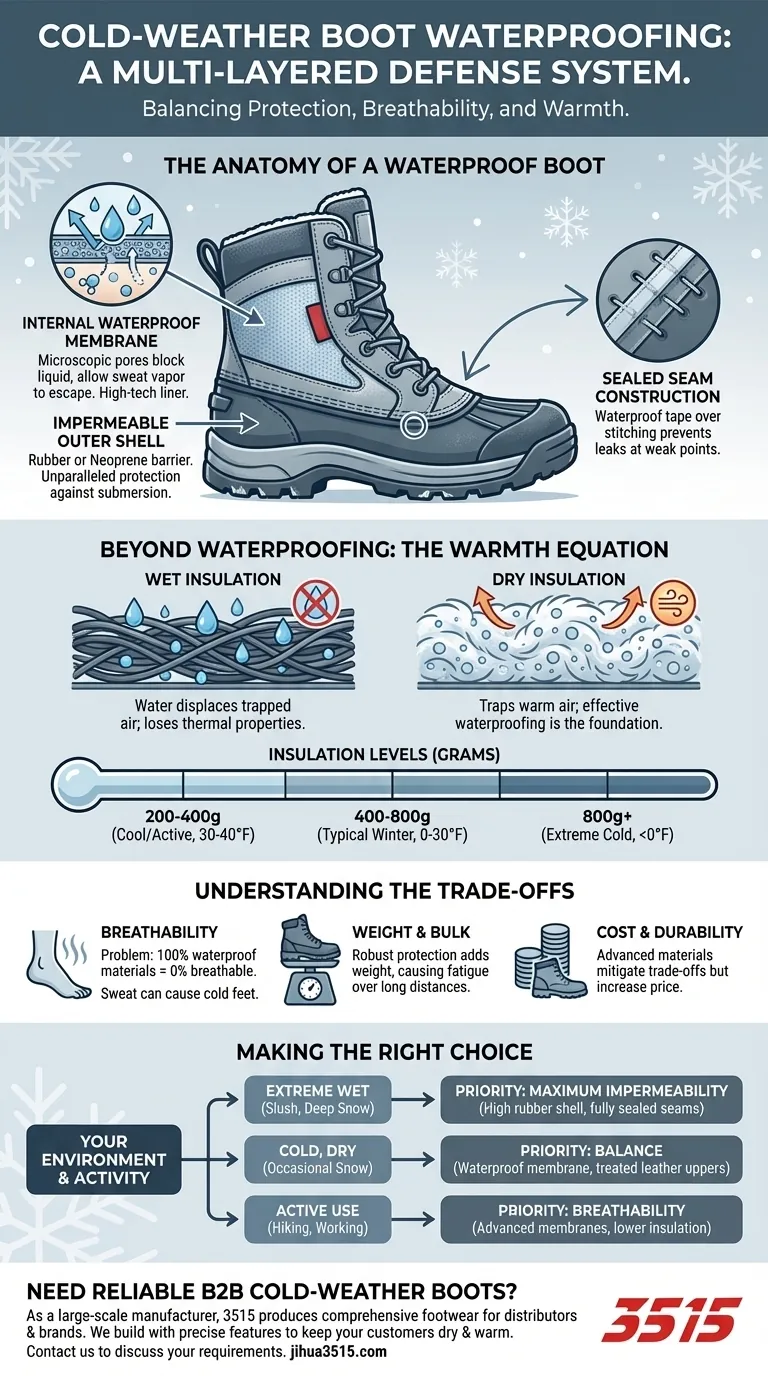

The Anatomy of a Waterproof Boot

To understand how a boot keeps you dry, you must look at it as a system of components working together. Each layer serves a distinct purpose in blocking external moisture while ideally managing internal sweat.

The Internal Waterproof Membrane

A key feature in many modern boots is a waterproof, breathable membrane. This is essentially a high-tech sock-like liner built between the outer material and the inner insulation.

These membranes contain microscopic pores that are too small for liquid water droplets to pass through but large enough for water vapor (sweat) to escape. This is the primary defense against leaks in boots made from materials like leather or synthetics.

The Impermeable Outer Shell

Some boots rely on inherently waterproof materials for their main structure. This is most common in the lower portion of the boot, which sees the most contact with snow and slush.

Rubber and neoprene are the most common examples. They are completely impermeable, offering unparalleled protection against submersion. This is why many "pac boots" feature a distinct rubber lower shell mated to a more flexible upper.

Sealed Seam Construction

Stitching is a weak point in any waterproof gear. Every needle hole is a potential entry point for water.

High-quality waterproof boots solve this with sealed seams. A special waterproof tape is applied over the seams on the inside of the boot, creating a barrier that ensures the boot's entire structure is secure against leaks. This is a critical feature that separates truly waterproof boots from merely water-resistant ones.

Beyond Waterproofing: The Warmth Equation

Keeping feet dry is only half the battle in cold weather; they must also be warm. Waterproofing and insulation are separate features, but they are critically codependent.

How Dryness Enables Warmth

Insulation works by trapping air, which is then warmed by your body heat. If that insulation gets wet, the water displaces the trapped air, and the material loses nearly all of its thermal properties.

Effective waterproofing is therefore the foundation of a warm boot. It ensures the insulation can do its job properly.

Matching Insulation to Temperature

Insulation in boots is measured in grams. A higher number means more insulation and more warmth.

- 200-400g: Suited for cool days or high-activity levels (30-40°F).

- 400-800g: An excellent all-around choice for typical winter conditions (0-30°F).

- 800g+: Intended for extreme cold or sedentary activities like ice fishing (below 0°F).

Understanding the Trade-offs

No boot is perfect for every situation. Achieving total waterproofing introduces compromises that you must consider based on your intended use.

The Breathability Problem

The most significant trade-off is breathability. Materials like rubber that are 100% waterproof are also 0% breathable.

This can lead to your feet becoming wet from sweat, which in turn can make them feel cold. While breathable membranes help, they can be overwhelmed during intense activity, and their effectiveness is still limited.

Weight and Bulk

Robust waterproofing and heavy insulation add significant weight and bulk. This can lead to fatigue over long distances and may feel cumbersome for daily wear. Lighter boots are often more comfortable but may sacrifice some protection or durability.

Cost and Durability

Higher-end boots use advanced materials and construction techniques to mitigate the trade-offs between waterproofing, breathability, and weight. These boots are often more durable but come at a significantly higher price point.

Making the Right Choice for Your Needs

Your ideal boot depends entirely on your specific environment and activity level. Focus on the conditions you will face most often.

- If your primary focus is extreme wet conditions (slush, deep snow, standing water): Prioritize boots with a high rubber shell and fully sealed seams for maximum impermeability.

- If your primary focus is cold, dry weather with occasional snow: A boot with a waterproof membrane and treated leather uppers offers a better balance of breathability and protection.

- If your primary focus is active use (hiking, working outdoors): Look for boots with advanced breathable membranes to manage sweat and choose the lowest insulation level appropriate for the temperature.

Understanding these components allows you to select a boot that provides the right balance of protection and comfort for any winter condition.

Summary Table:

| Feature | Purpose | Key Materials/Examples |

|---|---|---|

| Waterproof Membrane | Blocks external water while allowing sweat vapor to escape | Gore-Tex, eVent |

| Impermeable Outer Shell | Provides primary barrier against moisture | Rubber, Neoprene |

| Sealed Seams | Prevents water from leaking through stitch holes | Waterproof tape applied to seams |

| Insulation (by weight) | Traps warm air; effectiveness depends on staying dry | 200-400g (cool/active), 400-800g (typical winter), 800g+ (extreme cold) |

Need reliable, high-performance cold-weather boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof and insulated shoes and boots, built with the precise features outlined above to ensure your customers stay dry, warm, and comfortable.

We can help you source or develop the perfect boot for your target market, balancing waterproofing, breathability, and insulation based on your specific needs.

Contact us today to discuss your requirements and explore how we can deliver quality and value to your business.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- How do breathable materials in insulated boots improve comfort? Master Moisture for All-Day Warmth

- What are the characteristics of Coast Guard boots? Durable, Compliant Footwear for Maritime Missions

- What are the professional requirements for military boots? Durability, Comfort & Compliance

- Why is durability important in military boots? It's a Prerequisite for Survival and Mission Success

- How should military boots be maintained? A Guide to Maximize Durability and Performance

- What are some limitations of combat boots? Heavy, Stiff, and Poorly Ventilated

- What are the main components of a military boot? A Guide to Durability & Performance

- What are the limitations of jungle boots in cold conditions? A Dangerous Mismatch for Cold Weather