Composite toe work boots are the definitive choice for professionals who require robust foot protection without the specific liabilities of steel. They are ideal for electricians, engineers, mechanics, and workers in high-security environments, as well as anyone who prioritizes lightweight comfort for long shifts in variable temperatures.

The decision to choose composite over steel is not about one being "better," but about matching the unique properties of the material to the specific hazards and demands of your work environment. Composite toes excel where electrical risk, metal detectors, and extreme temperatures are primary concerns.

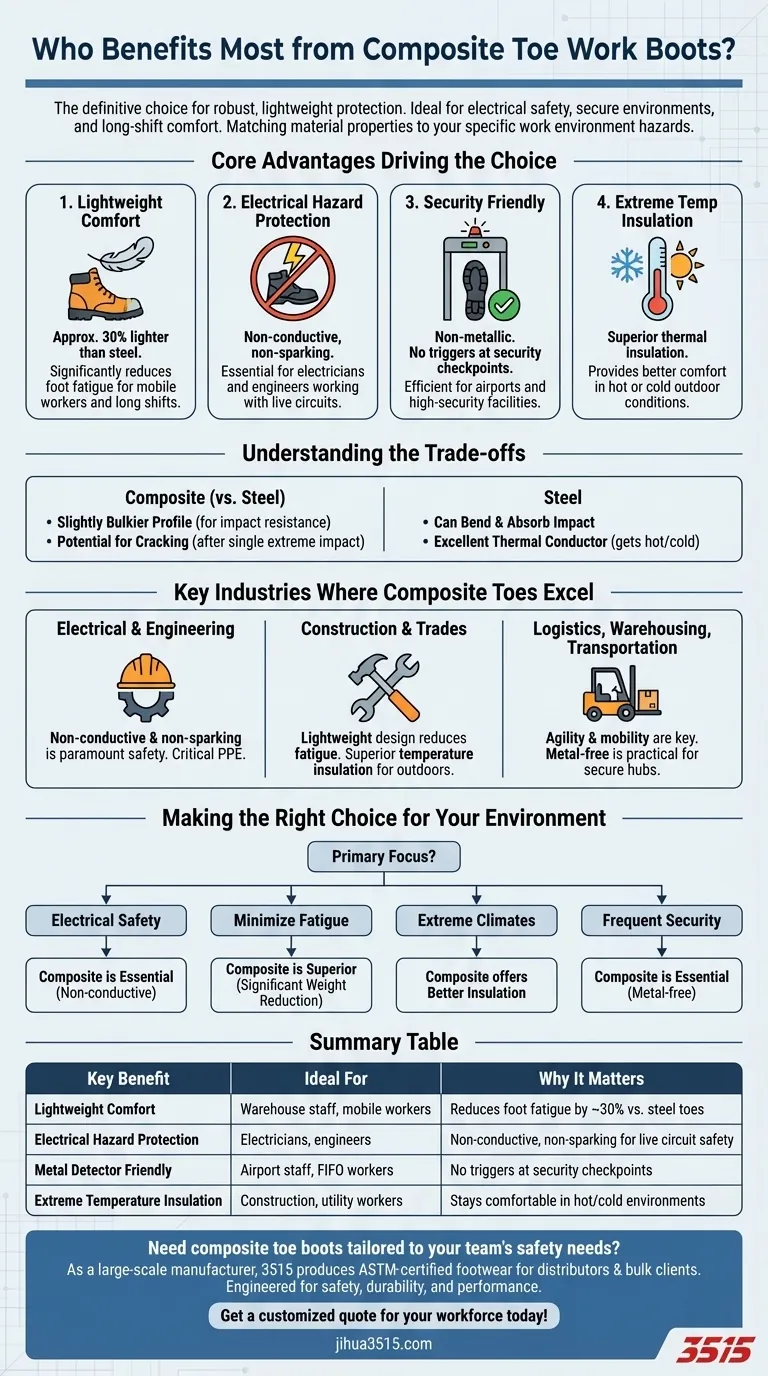

The Core Advantages Driving the Choice

While composite toe boots meet the same ASTM safety standards for impact and compression as their steel counterparts, their material composition provides distinct advantages for specific job functions.

Benefit 1: Reduced Weight and All-Day Comfort

A composite toe cap is typically about 30% lighter than a steel one. This significant weight reduction directly translates to less foot fatigue over the course of a long workday.

This makes them an excellent choice for mobile workers, warehouse staff, and anyone who is constantly on their feet. Less weight means less energy expended with every step.

Benefit 2: Superior Electrical Hazard Protection

Because they are crafted from non-metal materials like Kevlar, carbon fiber, or specialized plastics, composite toes do not conduct electricity.

This is a non-negotiable safety feature for electricians, engineers, and other tradespeople who work in environments with a risk of live circuits. This non-metallic property also prevents sparking.

Benefit 3: Unimpeded Access Through Security

The metal-free construction of composite toe boots means they will not trigger metal detectors.

This is a critical efficiency and convenience benefit for frequent travelers, FIFO (Fly-In/Fly-Out) workers, and personnel in law enforcement or high-security facilities like airports and power plants.

Benefit 4: Better Performance in Extreme Temperatures

Steel is an excellent thermal conductor, meaning it gets very cold in the winter and hot in the summer. Composite materials, by contrast, offer superior thermal insulation.

This feature provides significantly more comfort for anyone working outdoors for extended periods, such as those in construction, forestry, or utilities.

Understanding the Trade-offs

No single material is perfect for every application. To make an informed decision, it's crucial to understand the limitations of composite toe caps compared to steel.

Bulk and Profile

To achieve the same level of impact resistance as steel, a composite toe cap often needs to be slightly bulkier. While modern designs have minimized this, some workers may find them less streamlined than the slimmest steel toe boots.

Repeated Heavy Impacts

Both boot types must pass the same initial ASTM safety test. However, steel has a tendency to bend and absorb an impact, while composite materials can crack or shatter after a single, extreme crushing event. For environments with a risk of multiple, severe impacts, steel may offer more resilience after the initial incident.

Key Industries Where Composite Toes Excel

Certain professions are perfectly aligned with the unique benefits that composite materials offer, making them the clear and logical choice.

Electrical and Engineering

For electricians and engineers, the non-conductive, non-sparking nature of composite toe boots is the paramount safety consideration. This is the primary industry where this type of boot is not just a preference, but a critical piece of personal protective equipment.

Construction and General Trades

Workers in construction and other trades benefit immensely from the lightweight design, which reduces fatigue during long, physically demanding days. The superior temperature insulation is also a major advantage for those working outdoors year-round.

Logistics, Warehousing, and Transportation

In these fast-paced environments, mobility is key. The reduced weight of composite boots helps workers stay agile and comfortable. For those working in secure shipping hubs or airports, the metal-free design is a practical necessity.

Making the Right Choice for Your Environment

Your choice should be dictated by a clear-eyed assessment of your daily work environment and its specific hazards.

- If your primary focus is electrical safety: Composite is the only acceptable choice, as its non-metallic construction eliminates conductivity risk.

- If your primary focus is minimizing fatigue from walking or standing: The significant weight reduction of composite toes makes them the superior option for long days.

- If your primary focus is working in extreme hot or cold climates: Composite offers better thermal insulation for all-day comfort and safety.

- If your primary focus is passing through metal detectors frequently: Composite toes eliminate a daily hassle and are essential for secure job sites.

By matching the boot's material properties to your job's real-world demands, you ensure optimal safety, comfort, and performance.

Summary Table:

| Key Benefit | Ideal For | Why It Matters |

|---|---|---|

| Lightweight Comfort | Warehouse staff, mobile workers | Reduces foot fatigue by ~30% vs. steel toes |

| Electrical Hazard Protection | Electricians, engineers | Non-conductive, non-sparking for live circuit safety |

| Metal Detector Friendly | Airport staff, FIFO workers | No triggers at security checkpoints |

| Extreme Temperature Insulation | Construction, utility workers | Stays comfortable in hot/cold environments |

Need composite toe boots tailored to your team's safety needs? As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified composite toe footwear for distributors, brand owners, and bulk clients. Our boots are engineered for electrical safety, lightweight durability, and all-weather performance—backed by decades of industrial expertise.

Get a customized quote for your workforce today!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What types of misleading claims might manufacturers make about their work boots? Avoid False Safety Promises

- What additional safety features do the boots offer beyond toe protection? A Guide to Slip, Puncture & Electrical Safety

- What is the most secure boot lacing technique? Achieve a Locked-in Fit with Lock Lacing

- Is the toe box a critical component of boot fit? Focus on the 3 pillars for a perfect fit.

- How do durability and structural stability of industrial boots impact LBP prevention? Ensure Long-Term Spinal Health

- Why is restoration a cost-effective option for work boots? Extend Boot Life & Save Money

- How do employer replacement rules impact the use of work boots? A Guide to Proactive Safety

- What does the 'PR' in ASTM F2413-18 M/I/C EH PR MT stand for? Decoding Your Boot's Safety Label