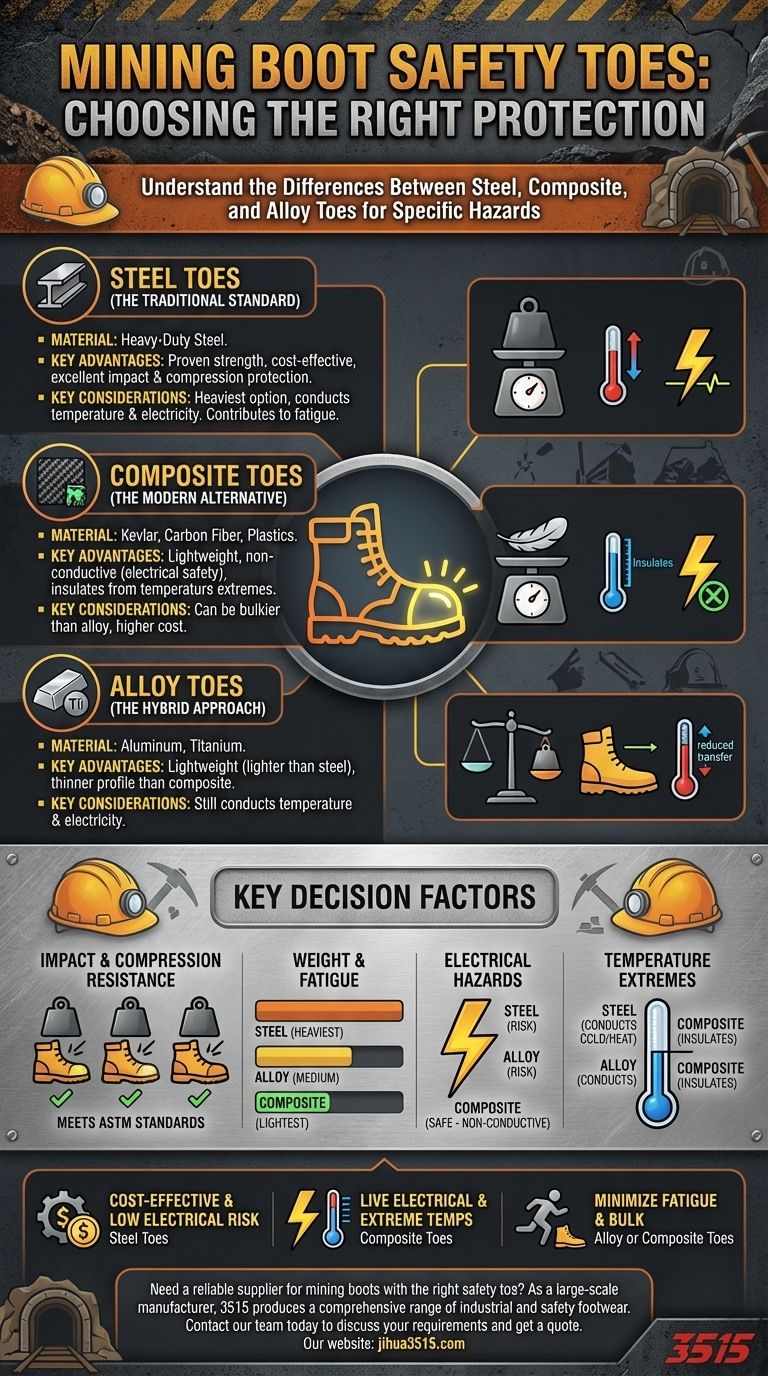

When selecting mining boots, the choice of safety toe is critical, and you will encounter three primary types: steel, composite, and alloy. Each is engineered to meet stringent safety standards for impact and compression, but they differ significantly in material, weight, and properties relevant to specific mining environments.

The decision between steel, composite, and alloy toes is not about finding the "strongest" option, as all must meet the same fundamental safety ratings. The correct choice depends entirely on balancing the specific hazards of your job—such as electrical risks or extreme temperatures—against factors like boot weight and all-day comfort.

A Breakdown of the Core Safety Toe Types

Understanding the material science behind each safety toe is the first step in making an informed decision. While all provide certified protection, their composition dictates their performance in different conditions.

Steel Toes: The Traditional Standard

Steel toes are the original and most common type of safety toe, made from heavy-duty steel. They have a long-standing reputation for providing excellent protection against impact and compression from heavy objects.

Their primary advantage is their proven strength. However, their main drawback is their weight, which can contribute to fatigue over long shifts. Steel is also conductive, transferring both temperature and electricity.

Composite Toes: The Modern Alternative

Composite toes are crafted from non-metallic materials like Kevlar, carbon fiber, or specialized plastics. This construction makes them significantly lighter than steel.

Their key benefit is that they do not conduct electricity, making them essential for electricians or those working near live currents. They also don't transfer heat or cold, providing better comfort in extreme temperature environments.

Alloy Toes: The Hybrid Approach

Alloy toes are made from lightweight metals, most commonly aluminum or titanium. They offer a protective middle ground between steel and composite options.

These toes provide the impact resistance required by safety standards but at a reduced weight compared to steel. They can often be made with a thinner profile than composite toes, resulting in a less bulky boot.

Key Decision Factors for Mining Environments

Choosing the right toe cap goes beyond a simple material preference. In a demanding field like mining, you must evaluate them based on the daily realities of the job.

Impact and Compression Resistance

It is a common misconception that one material is inherently "safer" than another. Any boot certified for safety must meet the same ASTM International standards for impact and compression resistance, regardless of whether the toe is steel, composite, or alloy.

Weight and Fatigue

The weight of your boots has a direct impact on fatigue over a 10- or 12-hour shift. Steel toes are the heaviest option, while composite toes are the lightest. Alloy toes fall in between, offering a noticeable weight savings over steel.

Electrical Hazards

This is a critical, non-negotiable factor. If you work in an environment with a risk of electrical shock, composite toes are the only appropriate choice. Their non-metallic construction provides vital protection against electrical conduction.

Temperature Extremes

Metal is an excellent conductor of temperature. In cold mining operations, steel and alloy toes can become very cold, leading to discomfort. Composite toes, being non-metallic, do not transfer cold, keeping your feet more comfortable.

Making the Right Choice for Your Role

Filter your options based on your most critical daily need to find the boot that serves you best.

- If your primary focus is on a proven, cost-effective solution in a low-risk electrical environment: Steel toes remain a durable and reliable industry standard.

- If you work around live electrical currents or in extreme hot or cold temperatures: Composite toes are the superior choice for their essential insulating and non-conductive properties.

- If your primary goal is to minimize fatigue over long shifts: Alloy or composite toes both offer significant weight savings that reduce physical strain.

- If you want lightweight protection with a less bulky fit: Alloy toes often provide a thinner profile than composite caps while still being much lighter than steel.

By evaluating your specific work conditions against these material properties, you can select a boot that delivers uncompromising safety tailored to your needs.

Summary Table:

| Safety Toe Type | Material | Key Advantages | Key Considerations |

|---|---|---|---|

| Steel Toes | Heavy-duty steel | Proven strength, cost-effective | Heaviest option, conducts temperature & electricity |

| Composite Toes | Kevlar, carbon fiber, plastic | Lightweight, non-conductive, insulates from temperature | Can be bulkier than alloy toes |

| Alloy Toes | Aluminum or titanium | Lightweight, thinner profile than composite | Still conducts temperature & electricity |

Need a reliable supplier for mining boots with the right safety toe?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, including models with steel, composite, and alloy toes, all designed to meet stringent international safety standards.

We can help you source or customize the perfect mining boots tailored to your specific workforce needs and environmental hazards. Contact our team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What innovative technologies enhance comfort in work boots? Achieve All-Day Comfort and Performance

- What are the key advantages of pull-on work boots? Slip On Speed, Safety & Durability

- What are the benefits of lace-up work boots? Achieve a Secure, Custom Fit for Maximum Safety

- What are the advantages of soft toe work boots? Boost Comfort & Mobility for Long Shifts

- How do the soles and midsoles of firefighter boots enhance safety? Ensure Foot Protection from the Ground Up

- What common features do safety toe work boots share regardless of style? Essential Protection Explained

- How should one choose insulated work boots based on climate and activity? Select the Right Insulation for Any Job

- What is a toe rand, and why is it optional? A Guide to Boot Durability