Choosing the right safety footwear is a foundational step in ensuring your personal safety on the job. The appropriate choice depends entirely on the specific hazards of your work environment, ranging from safety shoes for manufacturing and warehousing, to taller 6-to-8-inch boots for construction, and specialized waterproof boots for agriculture or mining.

The most effective way to select safety footwear is not to start with the shoe type, but to first conduct a thorough hazard assessment of your work environment. The specific risks—from falling objects to slippery surfaces—will dictate the necessary protective features, guiding you to the correct boot or shoe.

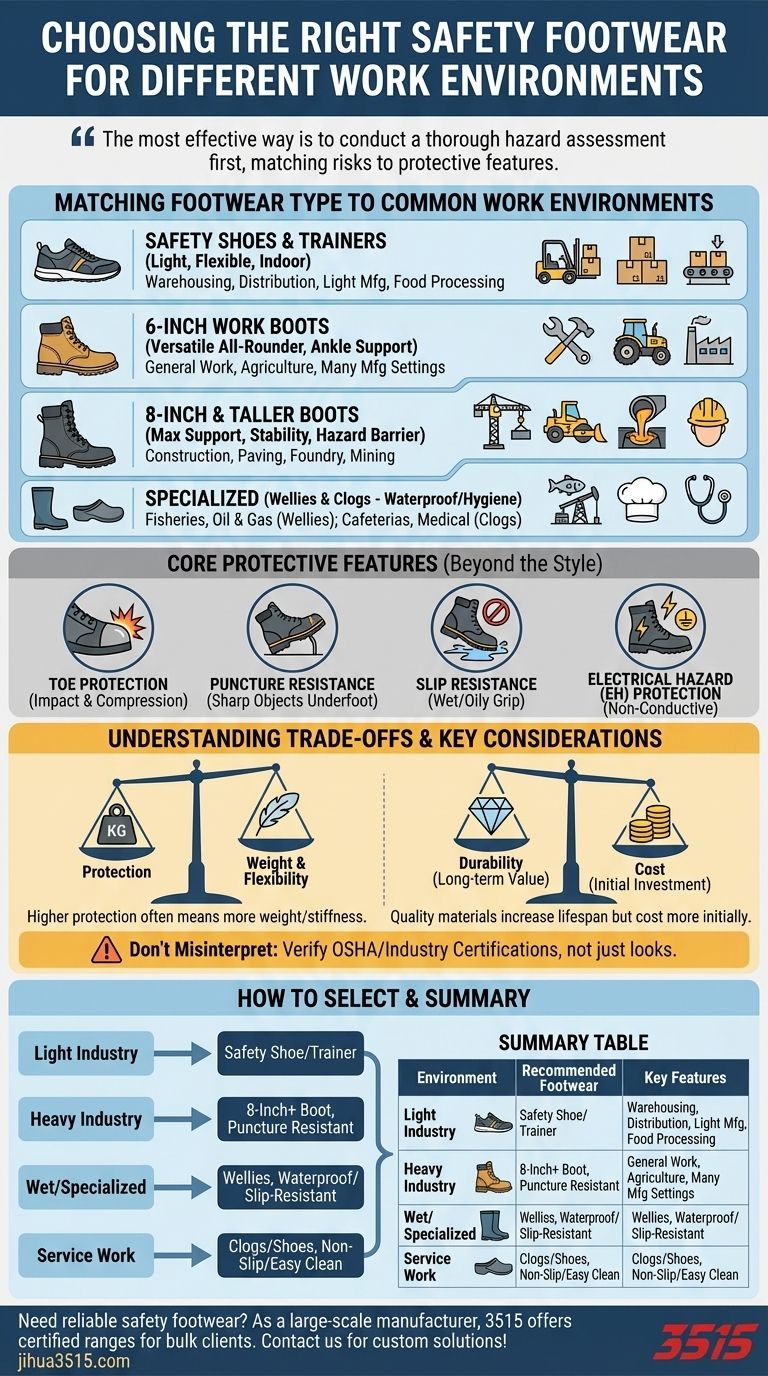

Matching Footwear Type to Common Work Environments

While the specific protective features are what truly matter, understanding the general categories of safety footwear provides a useful starting point. Each style is engineered with a certain type of work in mind.

Safety Shoes & Trainers

Safety shoes and trainers offer protection in a lighter, more flexible package. They are ideal for indoor or light-duty environments where mobility is important but toe protection is still required.

Common industries include warehousing, distribution, light manufacturing, and food processing.

6-Inch Work Boots

The 6-inch boot is the versatile all-rounder of the safety footwear world. It provides a solid balance of ankle support, protection, and comfort for a wide range of tasks.

These are a dependable choice for general work, agriculture, and many manufacturing settings.

8-Inch & Taller Work Boots

When a job requires maximum support and protection, an 8-inch or taller boot is the standard. The additional height provides enhanced ankle stability and a greater barrier against environmental hazards.

These are essential for more demanding jobs like construction, asphalt paving, foundry work, and mining.

Specialized Footwear (Wellies & Clogs)

Some environments have unique challenges that demand specialized footwear. Safety wellingtons (wellies) provide waterproof protection, while safety clogs offer slip resistance and hygiene.

Wellies are critical for fisheries, agri-food, oil & gas, and any consistently wet conditions. Clogs are often used by cafeteria workers and in some medical settings.

Beyond the Style: Understanding the Core Protective Features

The style of the boot is secondary to the specific safety technologies it contains. A true hazard assessment means identifying the risks and matching them to certified protective features.

Toe Protection

This is the most fundamental feature of safety footwear. It protects the toes from impacts (falling objects) and compression (heavy machinery). Toe caps are typically made from steel, aluminum alloy, or non-metallic composite materials.

Puncture Resistance

For environments where sharp objects like nails, scrap metal, or glass are underfoot, a puncture-resistant plate is built into the midsole. This is a non-negotiable feature on most construction and industrial sites.

Slip Resistance

Slips, trips, and falls are among the most common workplace injuries. Footwear with certified slip-resistant outsoles provides crucial grip on wet, oily, or otherwise slick surfaces, essential in food service and processing.

Electrical Hazard (EH) Protection

For anyone working near live electrical circuits, specialized EH-rated footwear is designed with non-conductive soles and heels. This feature can provide a secondary source of protection against accidental electrocution.

Understanding the Trade-offs

Selecting the perfect safety footwear always involves balancing competing priorities. Being aware of these trade-offs helps you make a more informed decision.

Protection vs. Weight & Flexibility

Generally, higher levels of protection come with increased weight and stiffness. A heavy-duty steel-toe boot with a puncture plate offers maximum defense but can lead to fatigue over a long day. A lighter composite-toe trainer is more comfortable but may not be suitable for heavy industrial work.

Durability vs. Cost

Higher-quality materials, such as Goodyear welt construction and premium leather, significantly increase the lifespan and durability of a boot. While the initial investment is higher, these boots often provide better long-term value and support than cheaper alternatives.

Misinterpreting the Requirements

Simply wearing a boot that looks "tough" is not enough. Many job sites require footwear that meets specific OSHA (Occupational Safety and Health Administration) or other industry standards. Always verify the required certifications for your job before making a purchase.

How to Select the Right Footwear for Your Needs

Base your decision on a clear-eyed assessment of your daily tasks and the risks they entail.

- If your primary focus is light industry (warehousing, manufacturing): A safety shoe or trainer with a certified protective toe cap is often the most practical choice for mobility and comfort.

- If your primary focus is heavy industry (construction, paving, foundry): An 8-inch or taller boot with puncture resistance and robust ankle support is necessary for maximum protection.

- If your primary focus is wet or specialized environments (agriculture, fisheries, oil & gas): Prioritize waterproof construction and slip-resistant outsoles, often found in safety wellingtons.

- If your primary focus is service work (kitchens, healthcare): Look for footwear with certified non-slip soles and features that are easy to clean and maintain.

Ultimately, investing the time to match your footwear to your specific workplace hazards is the most important safety step you can take.

Summary Table:

| Work Environment | Recommended Footwear Type | Key Protective Features |

|---|---|---|

| Warehousing / Light Manufacturing | Safety Shoes & Trainers | Toe Protection, Slip Resistance |

| Construction / Mining | 8-Inch & Taller Work Boots | Toe Protection, Puncture Resistance, Ankle Support |

| Agriculture / Oil & Gas | Safety Wellies (Wellingtons) | Waterproof, Slip Resistance |

| Food Processing / Kitchens | Safety Clogs | Slip Resistance, Easy to Clean |

Need reliable safety footwear for your workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. We offer footwear tailored to every work environment—from lightweight trainers for warehousing to heavy-duty boots for construction—ensuring compliance, durability, and comfort.

Let us help you equip your team with the right protection. Contact our experts today for competitive pricing and custom solutions!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What should be considered when choosing safety shoes for a specific work environment? A Guide to Perfect Hazard-to-Feature Matching

- What are the technical and construction advantages of professional-grade Safety Shoes? Enhance Stability and Grip

- Why is it beneficial to alternate between two pairs of work shoes? Extend Lifespan and Boost Foot Health

- Do firefighter boot standards vary by region or country? Navigating NFPA, EN, and AS/NZS Standards

- Why is slip-resistance a critical feature for safety shoes used in insecticide spraying? Prevent Workplace Falls

- Why is it important to prioritize fit when choosing work shoes? Prevent Fatigue & Injury for Long Shifts

- How does the midlayer of a safety boot contribute to comfort and stability? The Unseen Workhorse Explained

- How does the selection of high-performance materials impact the effectiveness of protective footwear? Key Benefits Explained