At its core, selecting a work boot outsole comes down to two primary materials: high-performance Rubber for all-purpose traction and durability, and Thermo Poly Urethane (TPU) for specialized resistance to chemicals and abrasion. The ideal choice is dictated entirely by the specific hazards of your work environment.

The outsole of your work boot is not just a layer of material; it is a piece of specialized safety equipment. Understanding the fundamental differences between materials is the first step toward ensuring you have the right protection for your specific job.

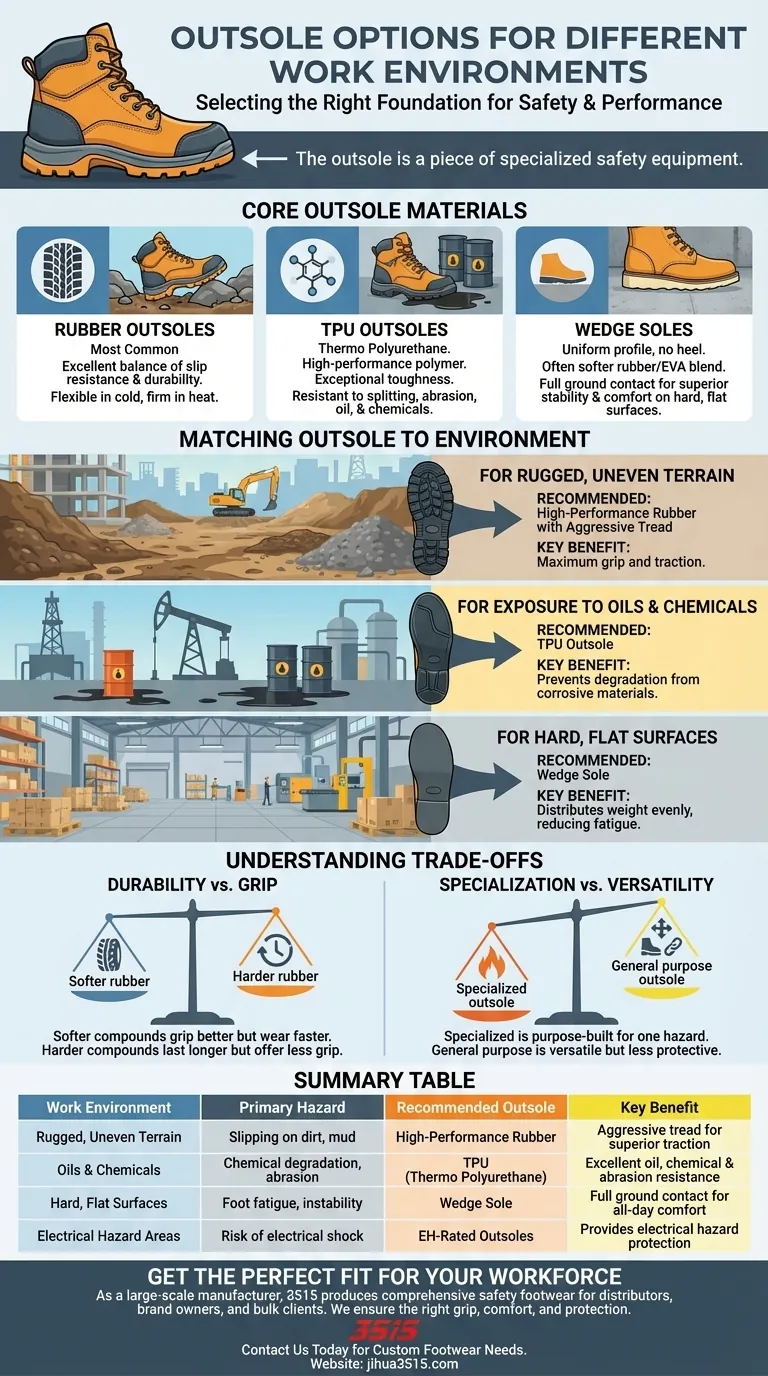

Understanding the Core Outsole Materials

The material composition of an outsole determines its most important properties, including its grip, durability, and resistance to environmental factors. While many hybrids exist, most fall into a few key categories.

Rubber Outsoles

Rubber is the most common material used for work boot outsoles for a reason. It offers an excellent balance of slip resistance and durability across a wide range of surfaces.

High-performance rubber compounds are specifically engineered to remain flexible in the cold and firm in the heat, providing reliable traction year-round on rugged terrain.

TPU (Thermo Polyurethane) Outsoles

TPU is a high-performance polymer known for its exceptional toughness. These outsoles are significantly more resistant to splitting, abrasion, oil, and chemicals than standard rubber.

This makes TPU the definitive choice for environments like oil rigs, automotive shops, and chemical processing facilities where exposure to harsh substances is a daily reality.

Wedge Soles

Often made from a softer rubber or a blend of EVA foam and rubber, wedge soles have a distinct, uniform profile without a separate heel.

This design provides full ground contact, offering superior stability and comfort for those who spend long hours on hard, flat surfaces like concrete floors in warehouses or manufacturing plants.

Matching the Outsole to Your Environment

The effectiveness of a work boot is measured by how well its features align with the demands of the job site. You must match the outsole's strengths to your environment's specific challenges.

For Rugged, Uneven Terrain

Jobs in construction, agriculture, and general outdoor labor require an outsole with an aggressive tread pattern and a defined heel. This design, typically made of durable rubber, provides maximum grip on dirt, mud, and gravel.

For Exposure to Oils and Chemicals

For mechanics, miners, or workers in the oil & gas industry, a TPU outsole is non-negotiable. Its chemical-resistant properties prevent the sole from degrading and losing its integrity when exposed to corrosive materials.

For Hard, Flat Surfaces

Warehouse staff, factory workers, and pavers benefit most from a wedge sole. The broad, flat surface distributes weight evenly, reducing pressure points and foot fatigue during long shifts on unforgiving concrete or asphalt.

Understanding the Trade-offs

No single outsole is perfect for every situation. Choosing the right one means understanding the inherent compromises between different designs and materials.

Durability vs. Grip

There is often a trade-off between how long a sole lasts and how well it grips. Softer rubber compounds provide excellent traction, especially on smooth or wet surfaces, but they tend to wear down more quickly.

Conversely, harder, more durable compounds can last much longer but may offer less grip, particularly in cold or wet conditions.

Specialization vs. Versatility

A highly specialized outsole, such as one with extreme heat resistance for foundry work, is purpose-built and performs exceptionally in that environment. However, it may be heavier or less comfortable for general-purpose use.

A general-purpose boot is more versatile but won't provide the same level of specialized protection. You must prioritize the single greatest hazard you face daily.

Making the Right Choice for Your Job

Your final decision should be a direct response to the primary demands of your workday. Use your main challenge as the guiding principle for your selection.

- If your primary focus is working outdoors on uneven ground: Prioritize a high-performance rubber outsole with a deep, aggressive tread pattern for maximum traction.

- If your primary focus is working with oils, solvents, or chemicals: Choose a TPU outsole for its superior chemical and abrasion resistance to ensure longevity and safety.

- If your primary focus is long hours on hard concrete floors: Select a wedge sole to maximize surface contact, providing superior comfort and support.

- If your primary focus is safety from electrical currents: Look for any outsole that is explicitly marked with an Electrical Hazard (EH) rating.

Choosing the right outsole is a critical investment in your daily safety, comfort, and performance.

Summary Table:

| Work Environment | Primary Hazard | Recommended Outsole | Key Benefit |

|---|---|---|---|

| Rugged, Uneven Terrain | Slipping on dirt, mud, gravel | High-Performance Rubber | Aggressive tread for superior traction |

| Exposure to Oils & Chemicals | Chemical degradation, abrasion | TPU (Thermo Polyurethane) | Excellent oil, chemical, and abrasion resistance |

| Hard, Flat Surfaces (e.g., concrete) | Foot fatigue, instability | Wedge Sole | Full ground contact for all-day comfort |

| Electrical Hazard Areas | Risk of electrical shock | EH-Rated Outsoles | Provides electrical hazard protection |

Get the Perfect Fit for Your Workforce

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes with specialized outsoles tailored to your specific industry hazards—from durable rubber for construction to chemical-resistant TPU for oil & gas.

We ensure your team has the right grip, comfort, and protection to enhance safety and productivity. Contact us today to discuss your custom footwear needs and receive a solution built for your environment.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What does impact resistance in ASTM standards entail? Achieve Maximum Toe Protection with I/75 Rating

- What should be considered regarding stiffness after wax treatment? A Trade-Off for Durability

- What should be considered when choosing light work boots for specific needs? Match Hazards to Features

- What should be prioritized when choosing work boots? The Ultimate Guide to Safety, Comfort & Durability

- Why is a proper fit important for work-safe boots? The Foundation of Safety, Comfort & Performance

- What are the standard boot width sizes and their corresponding labels? A Guide to the Perfect Fit

- How do quality boots reduce worker fatigue? Boost Productivity and Safety

- What is the compression resistance requirement in ASTM standards? Essential Guide to the 2,500-lb C Rating