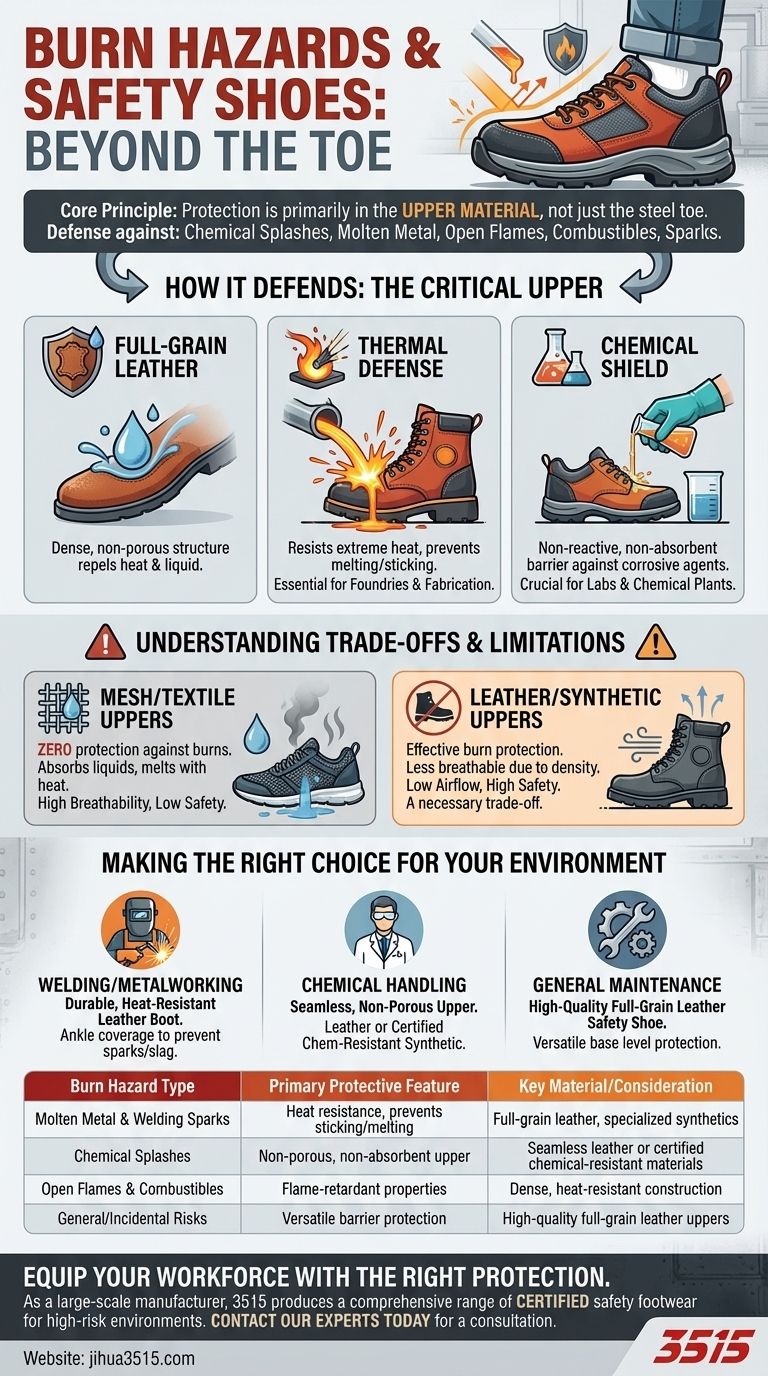

To be clear, safety shoes are engineered to protect your feet from a specific range of severe burn hazards. This protection extends beyond simple heat, covering dangers from chemical splashes, molten metal spills, open flames, combustible agents, and sparks from activities like welding.

The core principle of burn protection in safety footwear is not the steel toe, but the material of the shoe's upper. Materials like leather and specialized synthetics are chosen for their ability to repel dangerous substances and resist high temperatures, forming a critical barrier between the hazard and your skin.

How Safety Footwear Defends Against Burns

Understanding how a safety shoe provides protection allows you to assess its suitability for your specific work environment. The primary defense mechanism is the construction and material of the shoe's upper portion.

The Critical Role of Upper Materials

The most common material for burn protection is full-grain leather. Its dense, non-porous structure is naturally resistant to both heat and liquid penetration.

Unlike fabric or mesh, which can absorb chemicals or ignite easily, a leather upper forces hazardous substances to bead up and roll off.

Resisting High Temperatures (Thermal Burns)

Hazards like molten metal splashes and welding sparks present a risk of extreme, focused heat. A properly constructed safety shoe is designed to prevent these materials from melting through or sticking to the surface.

This type of footwear is essential in environments like foundries, fabrication shops, and heavy industrial manufacturing.

Guarding Against Chemical Splashes

In laboratories, cleaning services, or chemical plants, the primary burn risk comes from corrosive chemical agents.

The key protective feature here is a non-reactive and non-absorbent upper. It must prevent the chemical from soaking through to the foot, giving the worker time to follow proper decontamination procedures.

Understanding the Trade-offs and Limitations

Not all footwear labeled "safety shoe" offers adequate burn protection. Making the wrong assumption can lead to a false sense of security and serious injury.

Not All Safety Shoes Are Equal

Many modern safety shoes prioritize breathability and use mesh or textile uppers. While they may have a protective toe cap, these materials offer zero protection against chemical splashes or molten metal.

They can absorb liquids instantly or melt when exposed to high heat, potentially worsening an injury.

The Breathability Compromise

The same properties that make leather effective against burns—its density and low porosity—also make it less breathable than synthetic fabrics.

This is a necessary trade-off. For environments with genuine burn risks, prioritizing material resilience over maximum airflow is a non-negotiable safety requirement.

Specialized vs. General Protection

Standard leather work boots offer good all-around protection for incidental exposure. However, extreme environments require certified, specialized footwear.

For example, a foundry worker needs boots specifically rated for molten metal splashes (often called "met-guard" boots), which provide far more protection than a standard pair.

Making the Right Choice for Your Environment

Your specific workplace hazards must dictate your choice of footwear. Use this as a guide to select the appropriate level of protection.

- If your primary focus is welding or metalworking: You need a durable, heat-resistant leather boot that covers the ankle to prevent sparks and slag from entering.

- If your primary focus is handling chemicals: You require a shoe with a seamless, non-porous upper made of leather or a certified chemically-resistant synthetic.

- If your primary focus is general maintenance with incidental risks: A high-quality, full-grain leather safety shoe provides a versatile and effective base level of protection.

Ultimately, matching the shoe's material properties to your specific workplace hazards is the key to ensuring true foot safety.

Summary Table:

| Burn Hazard Type | Primary Protective Feature | Key Material/Consideration |

|---|---|---|

| Molten Metal & Welding Sparks | Heat resistance, prevents sticking/melting | Full-grain leather, specialized synthetics |

| Chemical Splashes | Non-porous, non-absorbent upper | Seamless leather or certified chemical-resistant materials |

| Open Flames & Combustibles | Flame-retardant properties | Dense, heat-resistant construction |

| General/Incidental Risks | Versatile barrier protection | High-quality full-grain leather uppers |

Ensure your workforce is equipped with the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of heat-resistant and chemically-resistant shoes and boots, designed to meet the specific demands of high-risk environments like foundries, chemical plants, and metalworking shops.

Contact our experts today for a consultation on the perfect safety footwear solution for your needs.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why is a high-precision digital dynamometer necessary for measuring the slip safety coefficient of footwear materials? Ensure Unrivaled Slip Prevention & Accuracy

- What is the primary function of a wide toe box in diabetic footwear? Essential Injury Prevention Guide

- How do industrial-grade safety shoes prevent accidents in freight handling? Grip, Stability & Injury Prevention

- What is the SB classification for safety shoes? A Guide to Basic Footwear Protection

- What does a dark grey rectangle with an M letter on safety footwear mean? It's Metatarsal Protection

- How do shoe lasts made from recyclable materials contribute to the sustainability of safety shoe manufacturing?

- What is the requirement for front foot protection under EN ISO 20345? The 200 Joule Safety Standard Explained

- Why are professional safety shoes required during heavy-duty girder erection? Essential Protection for Infrastructure