OSHA’s requirements for personal protective equipment (PPE) are not based on a simple checklist for each industry, but on a foundational principle: the employer must assess the specific hazards of the job and provide equipment to protect against them. While specific standards exist for gear like protective footwear, the core requirement is a formal hazard assessment that dictates the necessary protection for any given role.

The central takeaway is that OSHA does not mandate a universal list of PPE for every industry. Instead, it legally requires employers to perform a "hazard assessment" of their workplace to identify risks and then select and provide the appropriate PPE to mitigate those specific dangers.

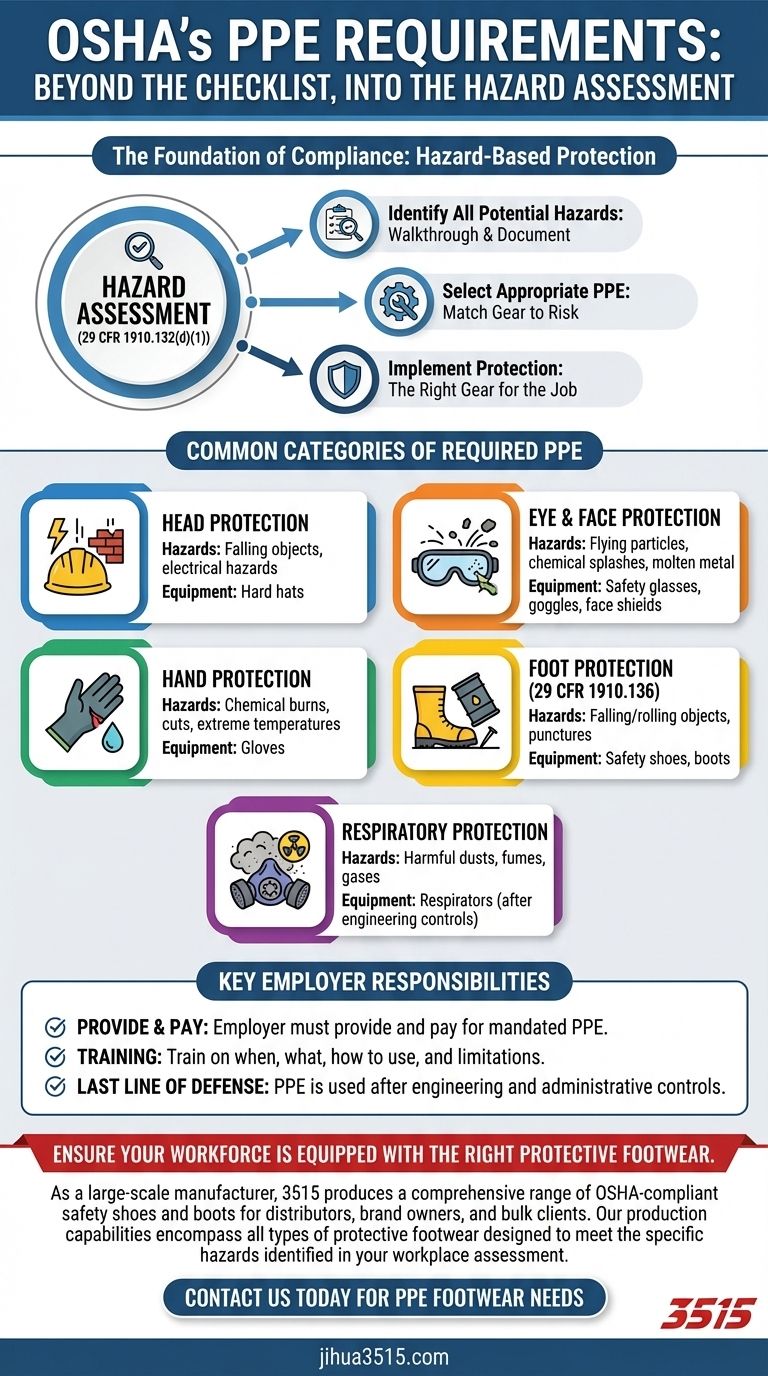

The Foundation of Compliance: The Hazard Assessment

The entire framework for OSHA's PPE standards rests on a single, critical process. Understanding this process is more important than memorizing a list of equipment, as it's the source of all PPE requirements.

What is a Hazard Assessment?

A workplace hazard assessment, as required by OSHA standard 29 CFR 1910.132(d)(1), is a formal process. Employers must walk through the worksite and identify all potential sources of injury or harm to employees.

This includes looking for physical hazards like falling objects, chemical hazards from splashes or fumes, radiological hazards, and any other potential dangers. The employer must document this assessment in a written certification.

From Assessment to Selection

Once hazards are identified, the employer's responsibility is to select the right type of PPE to protect the worker. The choice of equipment is directly linked to the nature and severity of the identified risk.

For example, a risk of falling tools dictates the need for head protection. The risk of chemical splashes dictates the need for specific types of eye and hand protection.

Common Categories of Required PPE

While the hazard assessment determines the final requirements, certain categories of PPE are commonly mandated across various industries based on typical risks.

Head Protection

This is required when employees are at risk from falling objects, bumping their heads against fixed objects, or coming into contact with electrical hazards. The most common form is a hard hat.

Eye and Face Protection

Employers must provide eye and face protection when workers are exposed to hazards from flying particles, molten metal, liquid chemicals, acids, or chemical gases. This includes safety glasses, goggles, and face shields.

Hand Protection

When employees face potential injury to their hands from skin absorption of harmful substances, severe cuts, chemical burns, or extreme temperatures, appropriate hand protection like gloves is required.

Foot Protection

As specified in OSHA 29 CFR 1910.136, employers must ensure employees use protective footwear in areas where there is a danger of foot injuries. This can be due to falling or rolling objects, or objects piercing the sole of the shoe.

Respiratory Protection

In environments where workers are exposed to harmful dusts, fogs, fumes, mists, gases, or vapors, employers must provide appropriate respiratory protection after first attempting to control the hazard through engineering controls (like ventilation).

Understanding Key Employer Responsibilities

Simply providing equipment is not enough. OSHA outlines several other critical duties for employers to ensure the PPE is effective.

The Employer's Duty to Provide and Pay

With very few exceptions, the employer is required to provide and pay for all OSHA-mandated personal protective equipment.

The Critical Role of Training

PPE is only effective if workers know how to use it. Employers must train each employee on when PPE is necessary, what kind is needed, how to properly put it on and take it off, and the equipment's limitations.

PPE as the "Last Line of Defense"

A core principle of workplace safety is that PPE should not be the first solution. Employers are expected to first try to eliminate or reduce hazards through engineering controls (e.g., machine guards) or administrative controls (e.g., changing work procedures). PPE is designed to protect workers from any remaining residual risk.

Making the Right Choice for Your Goal

Whether you are an employer seeking compliance or an employee focused on safety, understanding the core principles is key.

- If your primary focus is ensuring workplace compliance: Your most critical action is to conduct and document a thorough hazard assessment for every job role, as this is the legal foundation for all your PPE decisions.

- If your primary focus is personal safety as an employee: Understand the specific hazards of your job, actively participate in all PPE training, and never hesitate to ask for clarification on how to use your equipment correctly.

Ultimately, a safe workplace is a shared responsibility built on a clear and systematic assessment of real-world risks.

Summary Table:

| Common OSHA PPE Categories | Key Hazards Protected Against | Typical Equipment |

|---|---|---|

| Head Protection | Falling objects, electrical hazards | Hard hats |

| Eye & Face Protection | Flying particles, chemical splashes | Safety glasses, goggles, face shields |

| Hand Protection | Chemical burns, cuts, extreme temperatures | Gloves |

| Foot Protection | Falling/rolling objects, punctures | Safety shoes, boots |

| Respiratory Protection | Harmful dusts, fumes, gases | Respirators |

Ensure your workforce is equipped with the right protective footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of OSHA-compliant safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to meet the specific hazards identified in your workplace assessment.

Contact us today to discuss your PPE footwear needs and benefit from our expertise in durable, compliant safety solutions.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear

- How does high-precision laser cutting equipment enhance BC leather footwear? Achieve Superior Manufacturing Quality

- How do automated gait segmentation algorithms process complex signals? Data-Driven Biomechanical Insights Explained

- How do alligator and crocodile leathers differ in cowboy boots? A Guide to Luxury Exotics

- Why is rapeseed oil used in footwear wet simulation? Testing Sole Traction Against Viscous Contaminants

- How does a Bluetooth wireless communication module contribute to the portability of footwear gait detection systems?

- What is the significance of compliance testing equipment? Ensuring Global Safety Standards in Professional Footwear

- Why is it necessary to configure professional footwear for virtual pedestrian testing? Ensure Biomechanical Accuracy