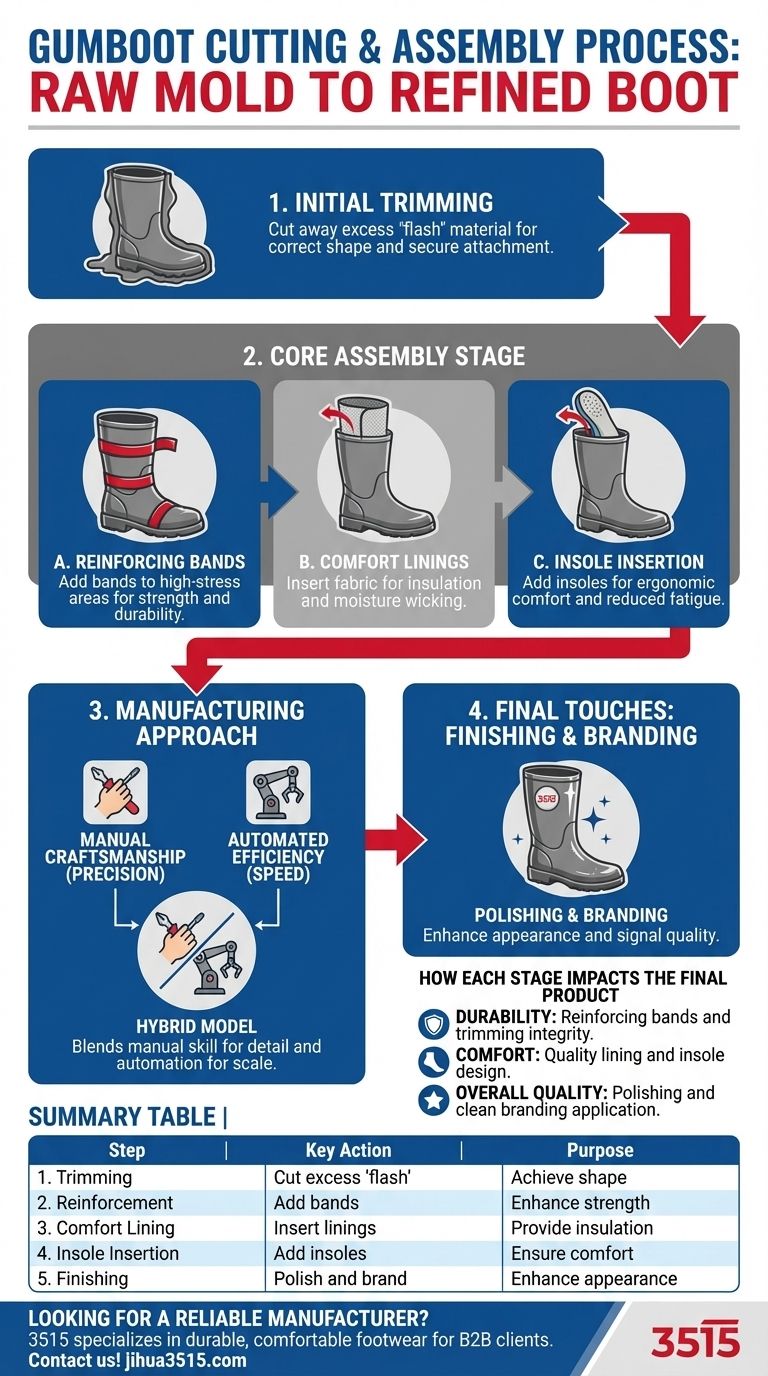

To cut and assemble gumboots, the process begins by trimming excess material from the initial mold. Key components are then added, including reinforcing bands for strength, fabric linings for comfort, and supportive insoles. Finally, the boots receive finishing touches like polishing and branding to complete their construction.

The assembly of a gumboot is a multi-stage process that transforms a simple molded shell into a functional, comfortable, and durable piece of footwear by layering structural, comfort, and aesthetic components.

From Raw Mold to Refined Boot

The journey from a raw rubber or PVC form to a finished gumboot involves several precise steps. Each stage is critical for ensuring the final product meets high standards of quality and performance.

The Initial Trimming

The very first step after the boot shell comes out of its mold is trimming. This involves carefully cutting away any excess material, often called "flash," that may have seeped out during the molding process.

Why Precision Matters

This stage is not just about aesthetics. A clean, precise trim ensures the boot has the correct shape and that all subsequent components, like reinforcing bands and soles, can be attached securely and seamlessly.

The Core Assembly Stage

With the boot trimmed to its proper form, the process moves to adding the essential components that provide structure, comfort, and support.

Adding Structural Reinforcement

Reinforcing bands are often added to high-stress areas of the boot. These bands provide extra strength and durability, preventing splits and enhancing the boot's overall lifespan, especially in rugged use conditions.

Integrating Comfort Linings

To ensure the boot is comfortable for extended wear, fabric linings are inserted. These linings can provide insulation, wick away moisture, and prevent chafing, creating a more pleasant internal environment for the foot.

Inserting Support Insoles

Finally, insoles are added to provide cushioning and arch support. This component is crucial for ergonomic comfort, reducing fatigue for the wearer during long periods of standing or walking.

Understanding the Manufacturing Approach

The assembly process is rarely a one-size-fits-all operation. Manufacturers often blend different techniques to achieve a balance between efficiency and quality.

Manual vs. Automated Techniques

Simpler, high-volume assembly steps may be automated for speed and consistency. However, more delicate tasks, such as applying reinforcing bands or detailed finishing, often require manual craftsmanship to ensure precision.

The Hybrid Model

Most modern gumboot manufacturing uses a hybrid approach. This combination of manual skill and automated efficiency allows for the production of high-quality boots at scale, meeting both performance and market demands.

The Final Touches: Finishing and Branding

The last phase of assembly focuses on the boot's appearance and final presentation.

Enhancing Visual Appeal

The assembled boots are often polished or buffed. This process smooths out any minor imperfections and gives the material its final sheen, enhancing its visual appeal and making it ready for the retail market.

Branding and Final Details

The last step is the application of brand logos and any other final decorative or functional details. This completes the boot's identity and signals its quality to the consumer.

How Each Stage Impacts the Final Product

Understanding the purpose of each assembly step helps you recognize the markers of a well-made gumboot.

- If your primary focus is durability: Pay attention to the presence of reinforcing bands and the quality of the trimming, as these are critical for long-term structural integrity.

- If your primary focus is comfort: The quality of the internal fabric lining and the thickness and shape of the insole are the most important factors for all-day wear.

- If your primary focus is overall quality: The final finish, including polishing and clean logo application, often reflects the manufacturer's overall attention to detail.

Ultimately, every step in the cutting and assembly process is designed to build upon the last, turning a basic shell into reliable and comfortable footwear.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Trimming | Cut away excess 'flash' material | Achieve correct shape and secure component attachment |

| 2. Reinforcement | Add bands to high-stress areas | Enhance strength and durability |

| 3. Comfort Lining | Insert fabric linings | Provide insulation and moisture wicking |

| 4. Insole Insertion | Add cushioned, supportive insoles | Ensure ergonomic comfort and reduce fatigue |

| 5. Finishing | Polish and apply branding | Enhance appearance and signal quality |

Looking for a reliable gumboot manufacturer? As a large-scale producer, 3515 specializes in creating durable, comfortable footwear for distributors, brand owners, and bulk clients. Our hybrid manufacturing approach combines automated efficiency with manual craftsmanship to deliver high-quality boots tailored to your needs. Contact us today to discuss your gumboot production requirements!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- What features should be considered when choosing wellies for toddlers and babies? A Guide to Safety & Comfort

- What is the recommended method for measuring foot length to find the right Wellington boot size? Get the Perfect Fit Every Time

- How do the heights of rain boots and snow boots compare? A Guide to Weather-Ready Footwear

- Why have Wellington boots become a topic of sustainability concern in the UK? The PVC Problem Explained

- What are the key materials needed to produce PVC rain boots? A Guide to the Essential Compound

- What are wellies and why are they significant in British culture? A Symbol of Resilience

- What are common mistakes to avoid when cleaning waterproof shoes? Preserve Your Gear's Performance

- What are Wellington boots and what are they typically used for? Unmatched Waterproof Protection for Wet Conditions