At a minimum, all safety footwear is governed by one of two primary international standards. In the United States, footwear must meet ASTM F2413 performance requirements, while in Europe, the standard is EN ISO 20345. Both standards mandate that the footwear includes a protective toe cap that can withstand significant impact and compression forces to protect the wearer from injury.

The core purpose of safety footwear standards is not just to test for toe-cap strength, but to create a clear, verifiable system for matching specific protective features to the actual hazards present in a work environment.

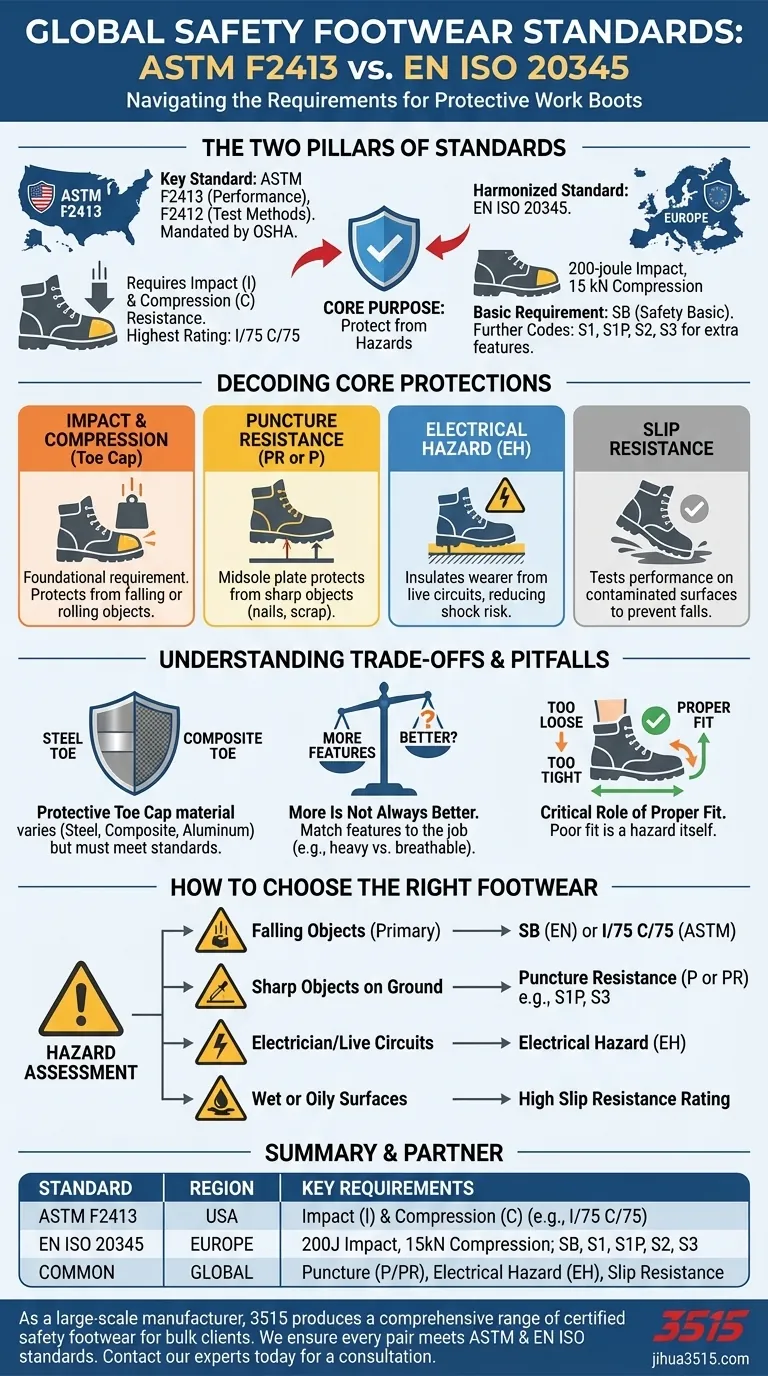

The Two Pillars of Safety Footwear Standards

While many countries have their own regulations, the U.S. and European standards are the most influential and form the basis for safety footwear requirements globally. They share the same fundamental goal but structure their requirements differently.

The U.S. Standard: ASTM F2413

The American Society for Testing and Materials (ASTM) sets the technical standards for safety footwear in the United States. OSHA (Occupational Safety and Health Administration) mandates that employers ensure their workers wear footwear compliant with these standards.

The key standard is ASTM F2413, which specifies the minimum performance requirements. The actual test methods used to verify this performance are detailed in a separate standard, ASTM F2412.

All footwear certified under ASTM F2413 must meet the requirements for impact (I) and compression (C) resistance for the toe area. The highest rating is typically noted as I/75 C/75.

The European Standard: EN ISO 20345

EN ISO 20345 is the harmonized standard across Europe. It requires that all safety footwear be equipped with a toe cap capable of withstanding a 200-joule impact and a 15 kilonewton (kN) compression force.

Footwear meeting this basic requirement is marked SB (Safety Basic). Further codes (S1, S1P, S2, S3) indicate additional protective features beyond the basic toe cap, creating a simple system for identifying the level of protection.

Decoding the Core Protections

The numbers and codes within these standards correspond to specific, testable protective features. Understanding what they mean is critical to selecting the right footwear.

Impact & Compression Resistance (The Toe Cap)

This is the foundational requirement of any safety shoe. It ensures the toe box can protect the foot from a heavy falling object (impact) or from being crushed under a heavy rolling object (compression).

Puncture Resistance (PR or P)

This feature involves a puncture-resistant plate built into the midsole of the shoe. It is designed to protect the foot from being pierced by sharp objects from below, such as nails or scrap metal on a construction site.

Electrical Hazard Protection (EH)

EH-rated footwear is designed to insulate the wearer from the ground. The soles can withstand a specific electrical charge, significantly reducing the risk of shock when accidentally stepping on a live circuit. This is a critical feature for electricians and maintenance workers.

Slip Resistance

One of the most common causes of workplace accidents is slips and falls. Standards for slip resistance test how a shoe's outsole performs on wet, oily, or otherwise contaminated surfaces, providing a rating that helps users choose appropriate footwear for their specific floor conditions.

Understanding the Trade-offs and Common Pitfalls

Choosing the right footwear goes beyond simply picking the one with the most safety codes. A clear understanding of the options and their implications is necessary.

"Safety Toe" vs. "Steel Toe"

The standards mandate a protective toe cap but do not specify the material. While steel is traditional, modern safety toes can be made of lighter materials like composites or aluminum, which still meet or exceed the required impact and compression standards.

More Features Is Not Always Better

A highly-specified boot, such as an S3-rated boot with water resistance and a puncture plate, may be perfect for outdoor construction. However, it may also be heavier and less breathable than a simpler S1 boot, making it uncomfortable and excessive for an indoor warehouse job where the primary risk is falling objects.

The Critical Role of Proper Fit

No standard can overcome the danger of poorly fitting footwear. A boot that is too loose can be a trip hazard, while one that is too tight can cause pain and long-term foot problems. A proper fit is essential for the shoe to perform as designed during an incident.

How to Choose the Right Certified Footwear

Your choice should be dictated by a risk assessment of your specific work environment. Use the official markings on the footwear to guide your decision.

- If your primary focus is protection from falling objects: Ensure your footwear is at least rated SB (EN ISO 20345) or has I/75 and C/75 ratings (ASTM F2413).

- If you work around sharp objects on the ground (e.g., construction): You need footwear with Puncture Resistance (P or PR), such as an S1P or S3 rated boot.

- If you are an electrician or work near live circuits: Your essential requirement is Electrical Hazard (EH) rated footwear to provide critical insulation.

- If you work on wet or oily surfaces: Prioritize a high rating for slip resistance on the specific surfaces you encounter to prevent falls.

Understanding these standards empowers you to move beyond simple compliance and select footwear that provides genuine, effective safety for your daily tasks.

Summary Table:

| Standard | Region | Key Requirements |

|---|---|---|

| ASTM F2413 | United States | Impact (I) & Compression (C) resistance (e.g., I/75 C/75) |

| EN ISO 20345 | Europe | 200-joule impact, 15 kN compression; SB, S1, S1P, S2, S3 ratings |

| Common Features | Global | Puncture Resistance (P/PR), Electrical Hazard (EH), Slip Resistance |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We ensure every pair meets or exceeds ASTM and EN ISO standards, providing the precise protection your workforce needs. Let us help you select or customize the right safety solution for your specific hazards. Contact our experts today for a consultation and quotation.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture