In the United States, safety-toe footwear is tested and rated according to two primary standards from ASTM International. The first is ASTM F2412, which defines the test methods, and the second is ASTM F2413, which specifies the minimum performance requirements the footwear must meet.

While the Occupational Safety and Health Administration (OSHA) mandates the use of protective footwear, it is the ASTM standards that define what "protective" actually means. Understanding the codes for impact (I/75) and compression (C/75) is the key to verifying true, certified protection.

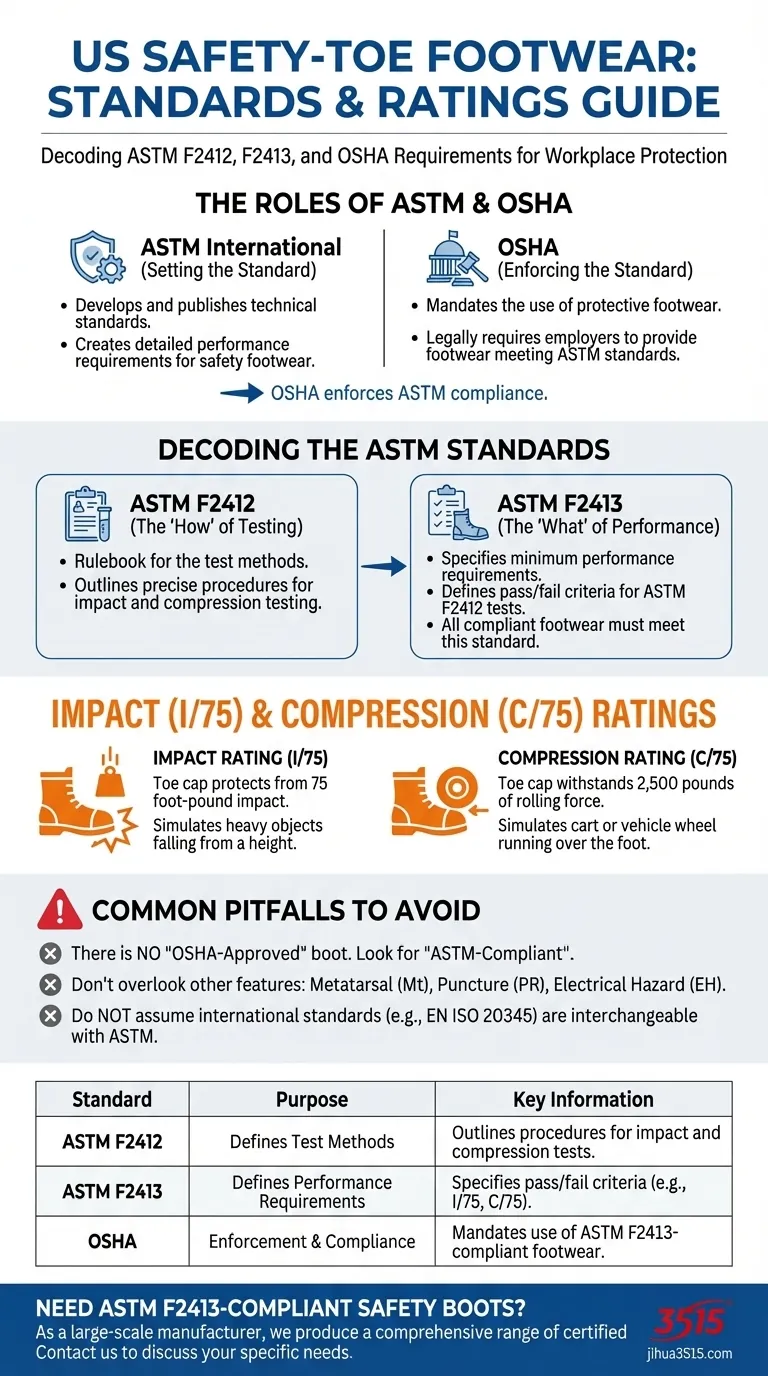

The Roles of ASTM and OSHA

To understand safety footwear ratings, you must first understand the two organizations involved. They have distinct but complementary roles in ensuring worker safety.

The Role of ASTM: Setting the Standard

ASTM International, formerly the American Society for Testing and Materials, is the organization that develops and publishes technical standards. They create the specific, detailed requirements for how safety footwear must perform under stress.

The Role of OSHA: Enforcing the Standard

The U.S. Occupational Safety and Health Administration (OSHA) is a government agency responsible for ensuring safe working conditions. OSHA does not write the footwear standards, but it legally requires employers to provide footwear that meets the standards set by ASTM.

Decoding the ASTM Standards

The label inside a compliant safety boot contains a line of code that explains exactly what it protects against. This code is based on two core ASTM standards.

ASTM F2412: The "How" of Testing

This standard is the rulebook for the test itself. It precisely outlines the procedures for testing impact and compression resistance, ensuring every certified boot is evaluated in the exact same way.

ASTM F2413: The "What" of Performance

This is the specification standard that states the footwear must meet or exceed. It defines the pass/fail criteria for the tests laid out in ASTM F2412. All compliant safety-toe footwear must meet this standard.

Impact (I/75) and Compression (C/75) Ratings

The most critical ratings for safety toes are for impact and compression.

The Impact rating (I/75) means the toe cap can protect the wearer's foot from a 75 foot-pound impact. This simulates a heavy object falling from a specific height.

The Compression rating (C/75) means the toe cap can withstand 2,500 pounds of rolling force, such as from a cart or vehicle wheel running over the foot.

Common Pitfalls to Avoid

Navigating safety standards can lead to common points of confusion. Being aware of them ensures you make the correct choice for your environment.

Confusing "OSHA-Approved" with "ASTM-Compliant"

There is no such thing as an "OSHA-approved" boot. OSHA requires that employers provide footwear that is compliant with ASTM F2413. The proof of compliance is the ASTM label inside the shoe, not a separate OSHA certification.

Overlooking Other Protective Features

The ASTM F2413 standard covers more than just toe protection. The label on the footwear will also list codes for other hazards, such as metatarsal protection (Mt), puncture resistance (PR), and electrical hazard protection (EH).

Assuming International Standards are the Same

The primary European standard is EN ISO 20345. While it serves a similar purpose, its testing methods and rating symbols are different from ASTM. The two standards are not interchangeable.

Making the Right Choice for Your Goal

When selecting or specifying footwear, look for the permanent label inside the tongue or collar of the boot to verify its protective qualities.

- If your primary focus is compliance for a US worksite: Look for a label that clearly states "ASTM F2413" followed by the specific I/75 and C/75 rating lines.

- If you are managing a safety program: Your policy must specify ASTM F2413-compliant footwear, and you should train employees to recognize the proper labeling to ensure they are protected.

- If you work in a global or European context: Be aware of the EN ISO 20345 standard and its unique symbols, as ASTM-compliant footwear may not be sufficient to meet local regulations.

By understanding how to read these critical standards, you can move beyond simple compliance and make an informed choice that truly protects you on the job.

Summary Table:

| Standard | Purpose | Key Information |

|---|---|---|

| ASTM F2412 | Defines Test Methods | Outlines procedures for impact and compression tests. |

| ASTM F2413 | Defines Performance Requirements | Specifies pass/fail criteria (e.g., I/75 for impact, C/75 for compression). |

| OSHA | Enforcement & Compliance | Mandates the use of ASTM F2413-compliant footwear in the workplace. |

Need ASTM F2413-compliant safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the rigorous standards for impact (I/75) and compression (C/75) protection your workforce requires.

Contact us today to discuss your specific needs and receive a quote. Let us help you protect your most valuable asset—your people.

Visual Guide

Related Products

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What is an OSHA approved boot? The Truth About Compliant Safety Footwear

- Why is industrial-grade PPE the most critical safety factor? Secure Your Site with the Final Line of Defense

- Why is a Shore hardness tester required for safety shoe outsoles? Ensure Slip Resistance and Material Quality

- What factors should be considered when choosing between composite, steel, or alloy toe boots? Find Your Perfect Fit

- What are the protective advantages of professional safety shoes? Crucial Safety for Fiber Extraction and Finishing

- What is the function of electrical insulation materials in the design of safety footwear? Vital High-Voltage Protection

- Why are composite toes popular in safety-toe boots? Achieve Superior Comfort & Protection

- What are the key considerations for choosing work shoes for warehouse employees? Prioritize Safety, Comfort & Durability