The primary standards governing safety footwear depend on your geographic location. In the United States, the Occupational Safety and Health Administration (OSHA) mandates foot protection under regulation 29 CFR 1910.136, which requires footwear to meet standards set by ASTM International. In Europe, the definitive standard is EN ISO 20345, with the latest version being EN ISO 20345:2022.

Understanding safety footwear is not about a single global rule, but about identifying your region's governing body (like OSHA or ISO) and then matching the specific performance ratings of the footwear to the actual hazards present in your work environment.

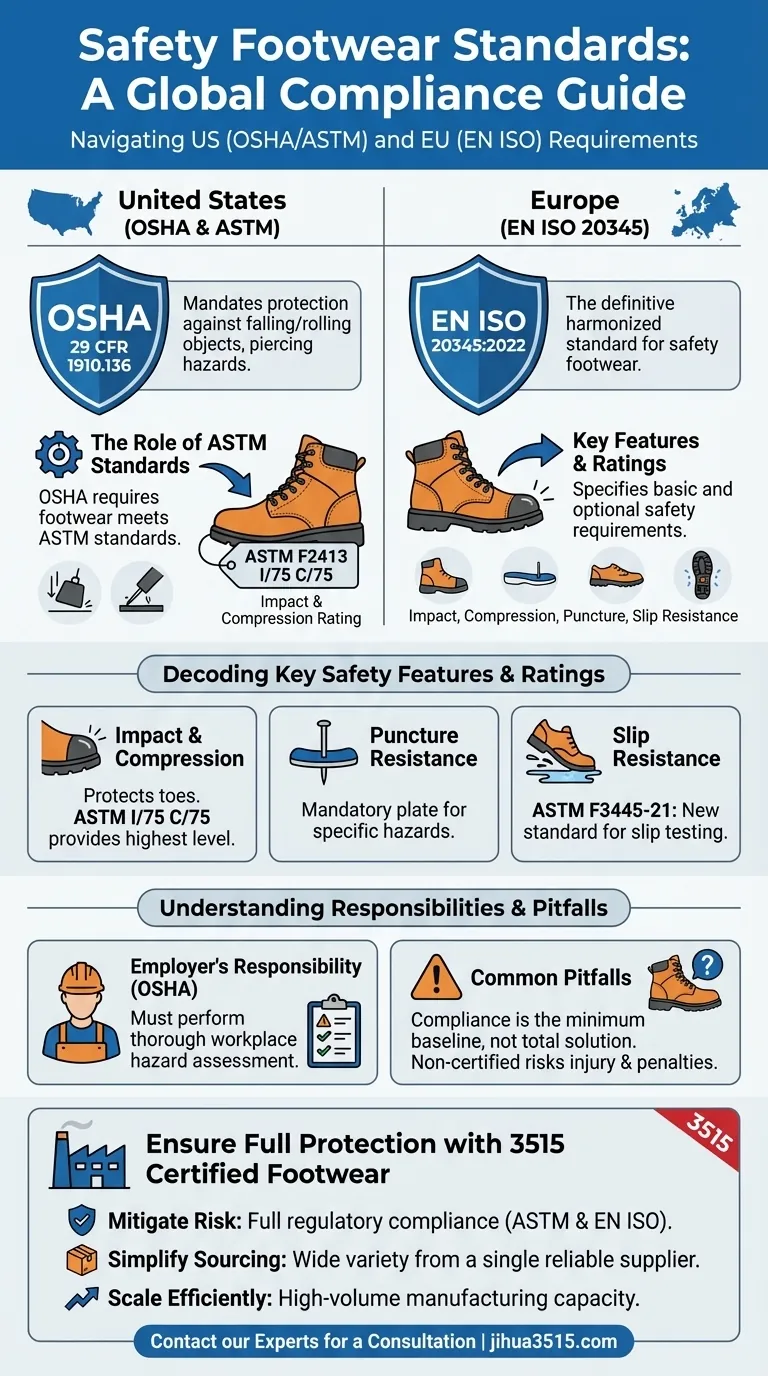

The Two Primary Regulatory Frameworks

Safety footwear compliance is fundamentally divided by geography. While the goal of protecting workers is universal, the standards and enforcement bodies differ significantly between the United States and Europe.

In the United States: OSHA and ASTM

The Occupational Safety and Health Administration (OSHA) is the regulatory body that sets the legal requirements for workplace safety.

OSHA's rule for foot protection, 29 CFR 1910.136, states that employers must ensure employees use protective footwear when facing dangers from falling objects, rolling objects, or objects that could pierce the sole.

The Role of ASTM Standards

OSHA does not certify footwear itself. Instead, it requires that safety footwear meets or exceeds the standards developed by ASTM International (formerly the American Society for Testing and Materials).

An ASTM-compliant boot will be marked with its specific performance rating, such as I/75 C/75, indicating the highest level of impact and compression resistance.

In Europe: The EN ISO 20345 Standard

For countries within the European Union and many others that follow its lead, the governing standard is EN ISO 20345.

This single, harmonized standard specifies the basic and optional requirements for safety footwear. The most recent update is EN ISO 20345:2022, which supersedes the previous 2011 version.

Decoding Key Safety Features and Ratings

Standards exist to verify that specific protective features perform as expected. Understanding these features is critical to selecting the right footwear.

Impact and Compression Resistance

This is the most fundamental feature, protecting the toes from falling objects and crushing forces. It is typically achieved with a built-in toe cap, which can be made of steel, aluminum, or composite materials.

The common "75" rating from ASTM signifies the highest level of protection available for both impact and compression.

Puncture Resistance

For environments like construction sites where sharp objects like nails are a hazard, a puncture-resistant plate is embedded in the midsole.

This feature is a mandatory requirement for certain safety ratings under both ASTM and EN ISO standards.

Slip Resistance

Slips, trips, and falls are among the most common workplace injuries. As a result, slip resistance has become a major focus of safety standards.

A new dedicated standard, ASTM F3445-21, was created to provide a universal specification for testing and rating the slip resistance of footwear, helping safety managers make more informed choices.

Understanding Responsibilities and Common Pitfalls

Achieving compliance is more than just buying a boot with a safety label. It involves a clear understanding of responsibility and the limitations of the standards themselves.

The Employer's Core Responsibility

According to OSHA, the duty falls on the employer to perform a thorough hazard assessment of the workplace.

This assessment dictates the specific type of protection required, and the employer must ensure every affected employee wears the appropriate footwear.

Compliance is the Floor, Not the Ceiling

A boot can be fully compliant with a given standard but still be the wrong choice for a specific task.

For example, a standard steel-toed boot offers no protection from chemical splashes or electrical hazards unless it is specifically rated for those risks. The standard is the minimum baseline, not the complete solution.

The Risk of Non-Certified Footwear

Using footwear that is not properly certified to the required standards not only exposes workers to significant injury but also places the employer at risk of legal and financial penalties for non-compliance.

Making the Right Choice for Your Goal

Your path to selecting the correct footwear depends entirely on your operational context and safety objectives.

- If your primary focus is US regulatory compliance: You must conduct a workplace hazard assessment and select footwear that is certified to the relevant ASTM standards for the identified risks.

- If your primary focus is European market compliance: Ensure all footwear is certified and clearly marked according to the

EN ISO 20345:2022standard. - If your primary focus is maximizing worker protection: Start with the required regional standard as your baseline, and then select footwear with additional protective features that directly address the unique and specific hazards of your environment.

Ultimately, choosing the right safety footwear is a critical act of proactive risk management.

Summary Table:

| Standard / Region | Key Governing Body | Primary Standard | Key Focus |

|---|---|---|---|

| United States | OSHA (Regulation: 29 CFR 1910.136) | ASTM F2413 | Impact, compression, and puncture resistance. |

| Europe / International | European Committee for Standardization | EN ISO 20345:2022 | Basic and optional safety requirements for footwear. |

Ensure Your Team is Fully Protected with Compliant Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, rigorously tested to meet ASTM (US) and EN ISO 20345 (EU) standards.

We help you:

- Mitigate Risk: Ensure full regulatory compliance and protect your workforce from workplace hazards.

- Simplify Sourcing: Access a wide variety of styles and safety ratings from a single, reliable supplier.

- Scale Efficiently: Benefit from our high-volume manufacturing capacity and competitive pricing.

Ready to equip your team with the right protection? Contact our experts today for a consultation on your specific safety footwear needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.