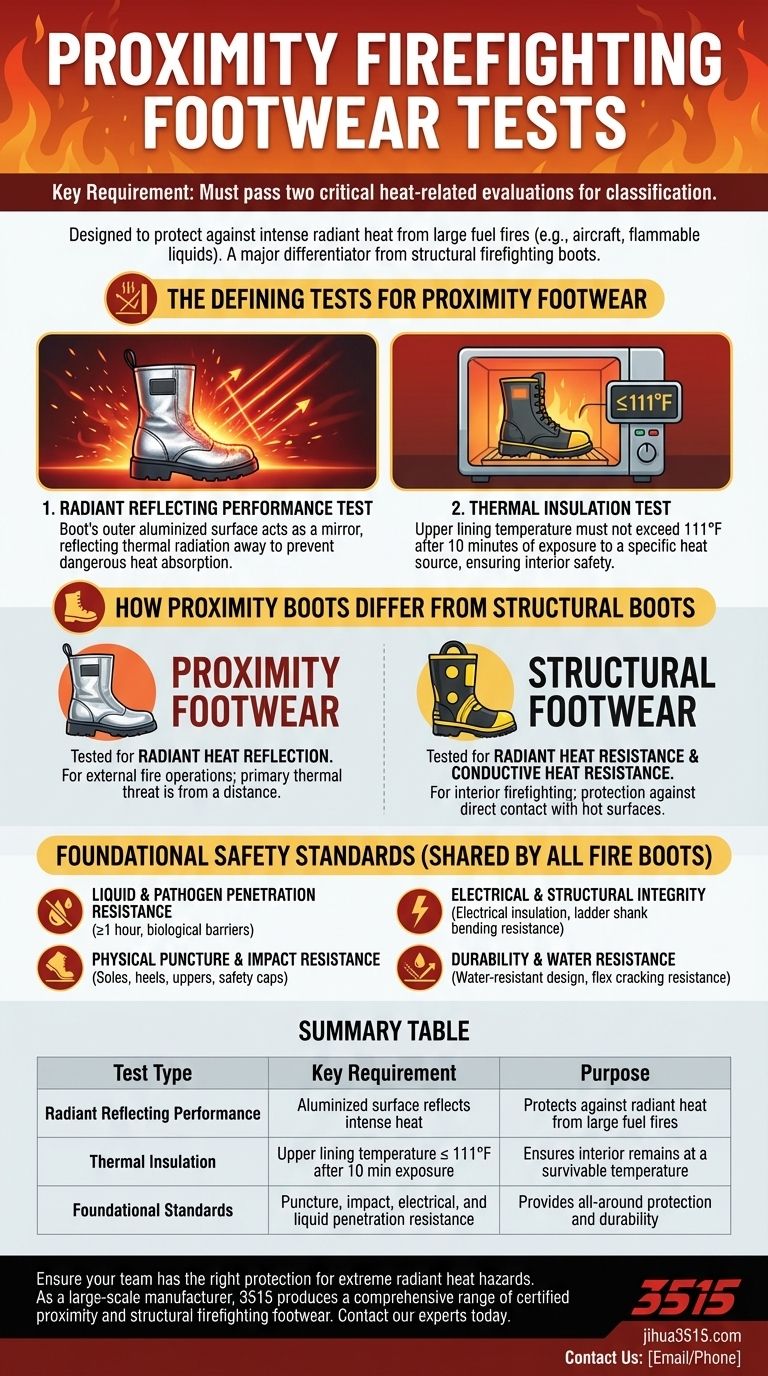

For a boot to be classified for proximity firefighting, it must pass two specific and critical heat-related evaluations: a radiant reflecting performance test and a demanding thermal insulation test. These standards are designed to protect the wearer from the intense radiant heat characteristic of large fuel fires, such as those involving aircraft or flammable liquids.

The key differentiator for proximity firefighting footwear is its specialized ability to reflect intense radiant heat, a performance standard not required for standard structural firefighting boots which are tested for heat resistance and conduction instead.

The Defining Tests for Proximity Footwear

Proximity firefighting involves operating near extreme external heat sources without direct entry. The testing standards for the footwear directly reflect this unique hazard.

Radiant Reflecting Performance Test

This test measures the boot's outer material's ability to act as a mirror against intense heat. The aluminized surface is designed to reflect thermal radiation away from the firefighter, preventing the boot from absorbing dangerous amounts of energy.

Thermal Insulation Test

This evaluation confirms that the boot can protect the wearer's foot from the heat that does get absorbed. The standard requires that the upper lining temperature does not exceed 111°F when exposed to a specific heat source for 10 minutes or less, ensuring the interior remains at a survivable temperature during a short-term exposure.

How Proximity Boots Differ from Structural Boots

While both are for firefighting, their specific heat protection tests target different scenarios. This distinction is crucial for selecting the correct personal protective equipment (PPE).

Proximity vs. Structural Heat Protection

Proximity footwear is tested for radiant heat reflection. It is designed for external fire operations where the primary thermal threat comes from a distance.

Structural footwear, in contrast, must pass a radiant heat resistance test and a conductive heat resistance test. These tests are designed for interior firefighting, where a boot may come into direct contact with hot surfaces like smoldering floors or embers.

Foundational Safety Standards for All Firefighting Boots

Beyond their specialized heat tests, proximity boots must also meet a comprehensive set of foundational standards shared with other types of firefighting footwear. These ensure all-around protection and durability.

Liquid and Pathogen Penetration Resistance

The footwear must resist liquid penetration for a minimum of one hour. It also requires protection against liquid or blood-borne pathogens, a critical barrier against biological hazards.

Physical Puncture and Impact Resistance

The soles, heels, and uppers must all pass a puncture resistance test. Additionally, the toes are protected by safety caps that meet stringent toe impact and compression resistance standards.

Electrical and Structural Integrity

Boots must provide protection from electrical hazards by passing an electrical insulation test. The integrated ladder shanks must also pass a bending resistance test to ensure they can support a firefighter's weight on a ladder rung without collapsing.

Durability and Water Resistance

The design must be inherently water-resistant. Finally, the boot is subjected to a flex cracking resistance test to ensure the puncture-resistance device does not break down from the stress of walking and bending over time.

Making the Right Choice for Your Goal

Understanding these specific testing requirements allows you to select the correct equipment for the hazard, ensuring both safety and operational effectiveness.

- If your primary focus is aircraft rescue or bulk flammable liquid fires: You must use proximity footwear, as only it is certified to reflect the extreme radiant heat of these incidents.

- If your primary focus is interior structural firefighting: Standard structural footwear is the appropriate choice, as it is specifically tested to resist heat from direct contact with hot surfaces.

- If you need a universal baseline for safety: Ensure any selected boot, regardless of type, meets the foundational standards for puncture, impact, electrical, and liquid penetration resistance.

Choosing footwear based on its specific, certified performance standards is the most reliable way to guarantee protection against the anticipated thermal hazard.

Summary Table:

| Test Type | Key Requirement | Purpose |

|---|---|---|

| Radiant Reflecting Performance | Aluminized surface reflects intense heat | Protects against radiant heat from large fuel fires (e.g., aircraft, flammable liquids) |

| Thermal Insulation | Upper lining temperature ≤ 111°F after 10 min exposure | Ensures interior remains at a survivable temperature during short-term exposure |

| Foundational Standards | Puncture, impact, electrical, and liquid penetration resistance | Provides all-around protection and durability for all firefighting scenarios |

Ensure your team has the right protection for extreme radiant heat hazards. As a large-scale manufacturer, 3515 produces a comprehensive range of certified proximity and structural firefighting footwear for distributors, brand owners, and bulk clients. Our boots are engineered to meet and exceed the critical safety standards detailed above. Contact our experts today to discuss your specific needs and get a quote for reliable, high-performance footwear.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- How did Western-style boots evolve into work boots? From Saddle to Job Site

- How do versatile work shoes maintain a balance between protection and comfort? Unlock Efficiency in Mixed Environments

- What features should electricians look for in work boots? Maximize Safety with EH-Rated Footwear

- What are the advantages of PVC work boots? Get Essential Protection at a Lower Cost

- What are the durability differences between low-pressure and high-pressure PU boots?

- What challenges do women face when transitioning from men's to women's work boots? Achieve a Perfect, Anatomical Fit

- What factors should be considered when choosing work shoes? The Ultimate Guide to Safety & Comfort

- Why is safety the most critical aspect of a work boot? Protect Your Workforce from Hazards