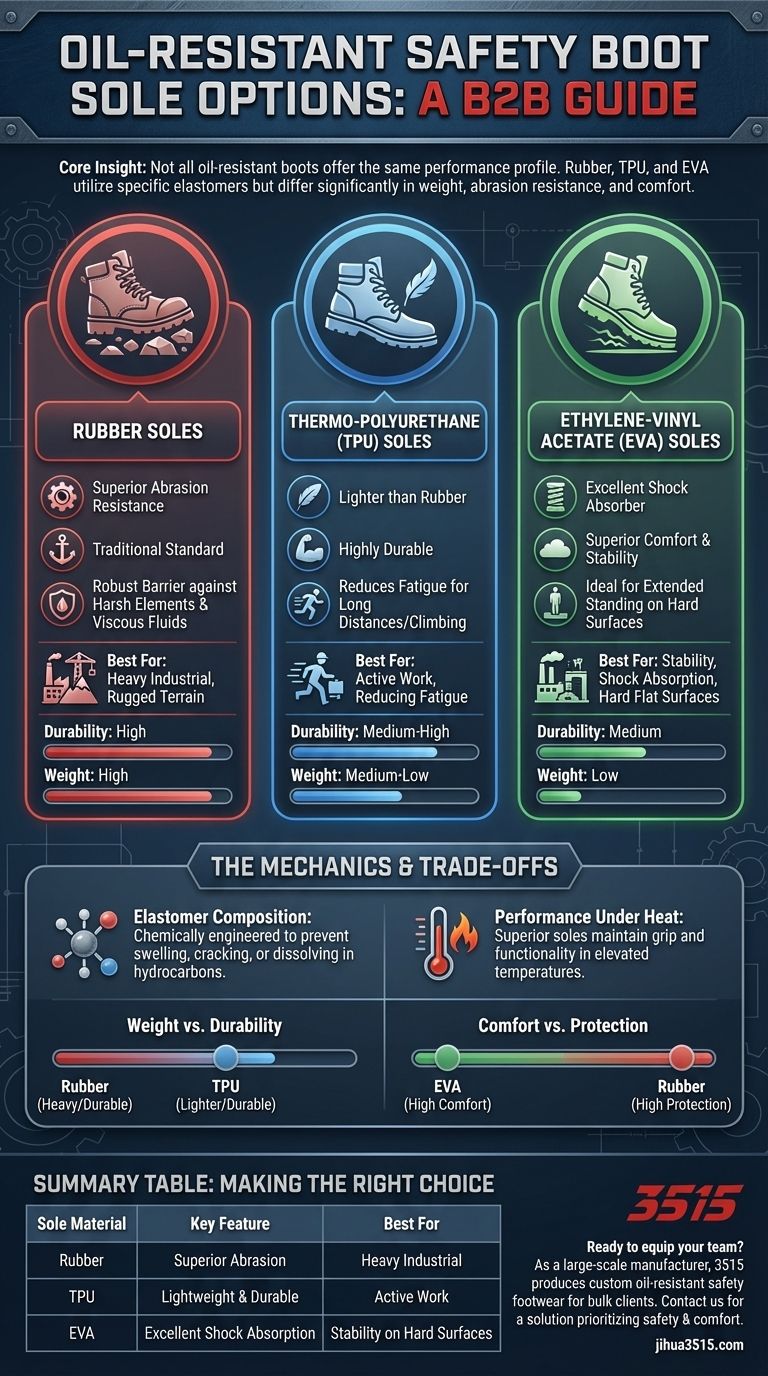

To ensure maximum protection and longevity in hazardous environments, the primary sole options for oil-resistant safety boots are Rubber, Thermo-Polyurethane (TPU), and Ethylene-Vinyl Acetate (EVA). While all three materials utilize specific elastomers to resist degradation when exposed to oil, they differ significantly in weight, abrasion resistance, and comfort profiles.

Core Insight: Not all oil-resistant boots offer the same performance profile. While Rubber provides the highest abrasion resistance for heavy industry, TPU offers a lighter, durable alternative, and EVA prioritizes stability and comfort for long-duration wear.

Analyzing the Material Options

When selecting safety footwear, the sole material dictates not just oil resistance, but how the boot interacts with the ground and supports the wearer.

Rubber Soles

Rubber remains the traditional standard for industrial environments. It is highly valued for its exceptional abrasion resistance and ability to withstand harsh elements.

In the context of oil resistance, rubber soles provide a robust barrier. They are designed to maintain structural integrity and traction even when coated in viscous fluids.

Thermo-Polyurethane (TPU) Soles

TPU represents a modern approach to safety footwear. The primary advantage of TPU over traditional rubber is that it is typically lighter while remaining highly durable.

For workers covering long distances or climbing frequently, the reduced weight of TPU can significantly lower fatigue levels without sacrificing oil resistance.

Ethylene-Vinyl Acetate (EVA) Soles

EVA is frequently chosen for its stability and comfort. It acts as an excellent shock absorber, making it ideal for roles that involve standing on hard surfaces for extended periods.

While EVA offers oil resistance, it is often utilized in the midsole or combined with other materials to balance comfort with the ruggedness required for the outer layer.

The Mechanics of Oil Resistance

Understanding "oil resistance" requires looking beyond the marketing label to the chemical engineering involved.

Elastomer Composition

Oil-resistant boots are manufactured using specific oil-resistant elastomers. These compounds are chemically engineered to prevent the sole from swelling, cracking, or dissolving when in contact with hydrocarbons.

Performance Under Heat

A critical differentiator for high-quality oil-resistant soles is their performance at elevated temperatures. As noted in technical specifications, superior soles maintain their functionality and grip even when the oil or the environment is hot.

Understanding the Trade-offs

Selecting the right sole involves balancing conflicting requirements. No single material is perfect for every scenario.

Weight vs. Durability

Rubber offers the highest durability and abrasion resistance, making it ideal for rough terrain like construction sites. However, it is generally the heaviest option, which can lead to leg fatigue over long shifts.

Comfort vs. Protection

EVA provides superior comfort and stability, acting as a cushion against impact. However, pure EVA may lack the extreme abrasion resistance of a dense rubber sole, making it better suited for factory floors than jagged outdoor terrain.

The Role of Upper Materials

The sole does not work in isolation. You must consider the trade-offs of the upper material as well. Leather adds durability but weight, while Nylon keeps the boot lightweight and breathable but may offer less physical protection against heavy debris.

Making the Right Choice for Your Goal

To select the correct boot, you must match the sole material to your specific environmental constraints.

- If your primary focus is heavy industrial durability: prioritize Rubber soles, as they offer the highest resistance to abrasion and harsh outdoor elements.

- If your primary focus is reducing fatigue during active work: prioritize Thermo-Polyurethane (TPU), which offers a durable but significantly lighter alternative to rubber.

- If your primary focus is stability and shock absorption: prioritize Ethylene-Vinyl Acetate (EVA), particularly if you work on flat, hard surfaces like concrete floors.

Select the material that solves your most critical daily challenge, rather than defaulting to the most common option.

Summary Table:

| Sole Material | Key Feature | Best For |

|---|---|---|

| Rubber | Superior abrasion resistance | Heavy industrial, rugged terrain |

| TPU | Lightweight & durable | Active work, reducing fatigue |

| EVA | Excellent shock absorption | Stability on hard surfaces |

Ready to equip your team with the right oil-resistant safety boots? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable, oil-resistant shoes and boots tailored to your industry's specific needs. Contact us today for a custom solution that prioritizes safety and comfort.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What is the main advantage of alloy toe shoes? Lighter, Stronger Protection for All-Day Comfort

- Can firefighter boots be resoled? A Guide to Safe & Cost-Effective Repair

- What is the primary ASTM standard for safety footwear? Your Guide to F2413-18 Compliance

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- How does the production process contribute to the lightness of composite toe caps? Achieve Superior Comfort & Safety

- What is the role of shock absorption in safety footwear? Protect Your Body from Repetitive Impact

- Why is ergonomic safety shoe design critical for worker performance? Boost Productivity with Specialized Footwear

- How do I choose security guard safety boots for my business? A Guide to Safety, Comfort & Compliance