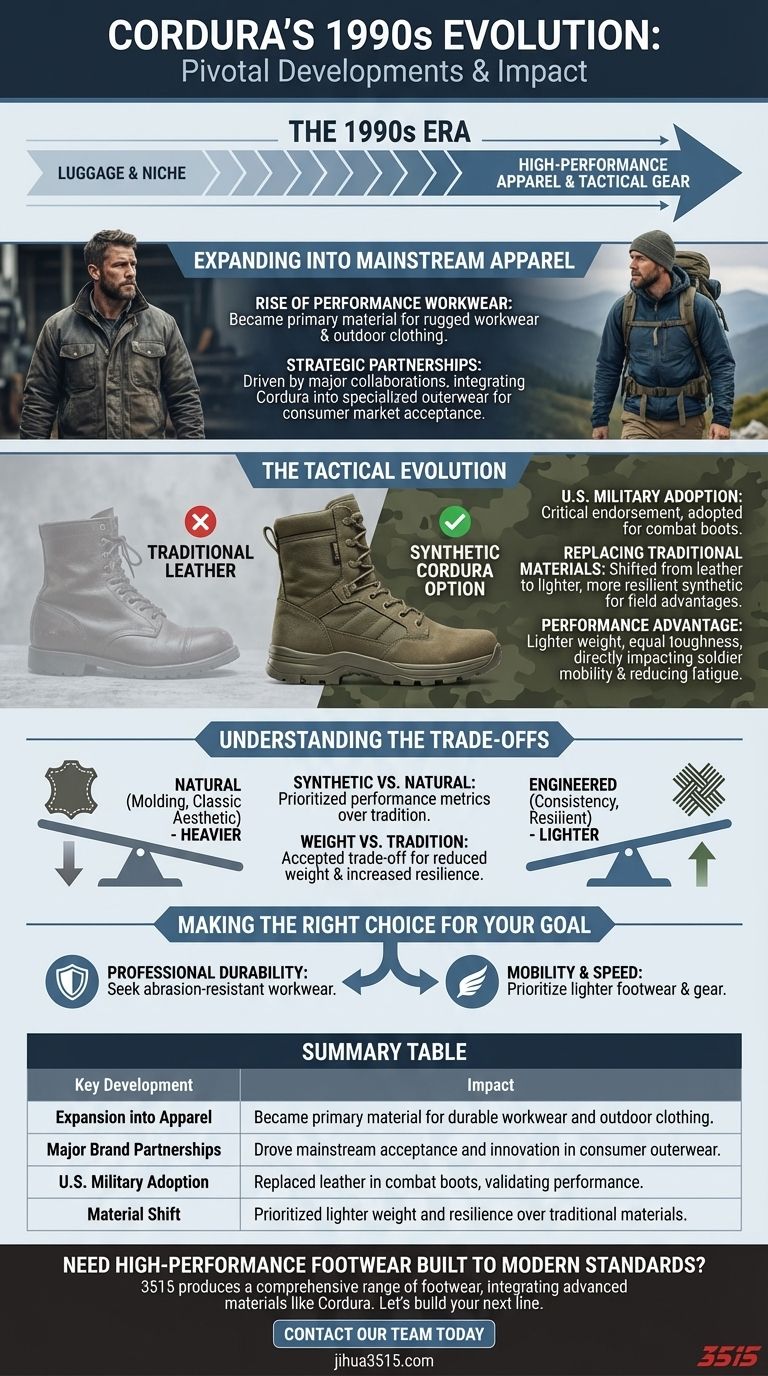

The 1990s marked a pivotal era for Cordura, expanding its utility beyond simple luggage into high-performance apparel and critical tactical gear. During this decade, the fabric became a standard for rugged workwear and outdoor clothing through strategic partnerships, while simultaneously redefining military footwear by replacing traditional leather with lighter, more resilient synthetic options.

The 1990s defined Cordura as a premier solution for both civilian durability and tactical resilience. By replacing traditional materials like leather in military applications and entering the mainstream workwear market, the fabric proved it could offer superior strength without the heavy weight penalties of the past.

Expanding into Mainstream Apparel

The 1990s signaled a shift where technical fabrics moved from niche accessories to essential wearable gear. This period established the material as a versatile textile capable of meeting diverse environmental demands.

The Rise of Performance Workwear

In this decade, the fabric moved out of the realm of pure accessory manufacturing. It became a widely used primary material for both workwear and outdoor apparel.

Strategic Partnerships

Growth was driven by collaboration rather than isolation. A major partnership during this period directly led to the creation of specialized outerwear incorporating the fabric, signaling its acceptance in the broader consumer market.

The Tactical Evolution

Perhaps the most significant validation of the material's performance came from the defense sector. The 1990s saw a distinct move toward modernizing soldier equipment.

Adoption by the U.S. Military

The U.S. military adopted Cordura specifically for use in combat boots. This was a critical endorsement of the fabric's reliability in life-critical situations.

Replacing Traditional Materials

This adoption marked a departure from historical standards. The military sought to replace traditional leather to gain specific performance advantages in the field.

The Performance Advantage

The switch was not merely for cost or ease of production. The new boots offered a lighter and more resilient alternative to the heavy footwear previously issued to soldiers, directly impacting soldier mobility.

Understanding the Trade-offs

While the 1990s solidified the fabric's reputation, the transition from traditional materials illustrates a key technical trade-off.

Synthetic vs. Natural

The move away from leather in combat boots highlighted a prioritization of performance metrics over tradition. While leather offers natural molding and a classic aesthetic, the industry shifted toward engineered consistency.

Weight vs. Tradition

The primary driver for this shift was weight reduction. The trade-off accepted during this era was the abandonment of the "heavy duty" feel of leather in exchange for a material that was lighter yet equally tough, reducing fatigue for the user.

Making the Right Choice for Your Goal

The developments of the 1990s provide a blueprint for how to select materials based on performance needs rather than convention.

- If your primary focus is professional durability: Seek out workwear that utilizes the abrasion-resistant standards established during the widespread adoption of this era.

- If your primary focus is mobility and speed: Prioritize footwear and gear that leverage the "lighter" properties validated by military testing, avoiding heavier traditional alternatives.

The 1990s successfully bridged the gap between industrial strength and wearable comfort, establishing the modern standard for high-performance textiles.

Summary Table:

| Key Development | Impact |

|---|---|

| Expansion into Apparel | Became a primary material for durable workwear and outdoor clothing. |

| Major Brand Partnerships | Drove mainstream acceptance and innovation in consumer outerwear. |

| U.S. Military Adoption | Replaced leather in combat boots, validating performance in critical use. |

| Material Shift | Prioritized lighter weight and engineered resilience over traditional materials. |

Need High-Performance Footwear Built to Modern Standards?

The 1990s proved that the right materials are crucial for performance and durability. As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, integrating advanced materials like those that defined Cordura's legacy.

Let's build your next line of high-performance footwear. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- How does systematic data analysis contribute to footwear manufacturing research? Enhance Quality with Logical Support

- What is the function of a programmable microcontroller board in smart assistive footwear? Explore the Central Brain

- In what way do environmental education tools contribute to consumer demand for green footwear? Boost Your Green Sales

- Why is a layer of soft EVA added above air cushions in pressure testing? Ensuring Accurate Foot Decompression Data

- How does an adaptive filter use hardware feedback to optimize UWB ranging in NLOS? Enhance Your Tracking Precision

- What is the origin of the high gloss patina finish? From Military Discipline to Sartorial Excellence

- How do circular economy-oriented manufacturing systems optimize footwear lifecycles? Boost Efficiency and Sustainability