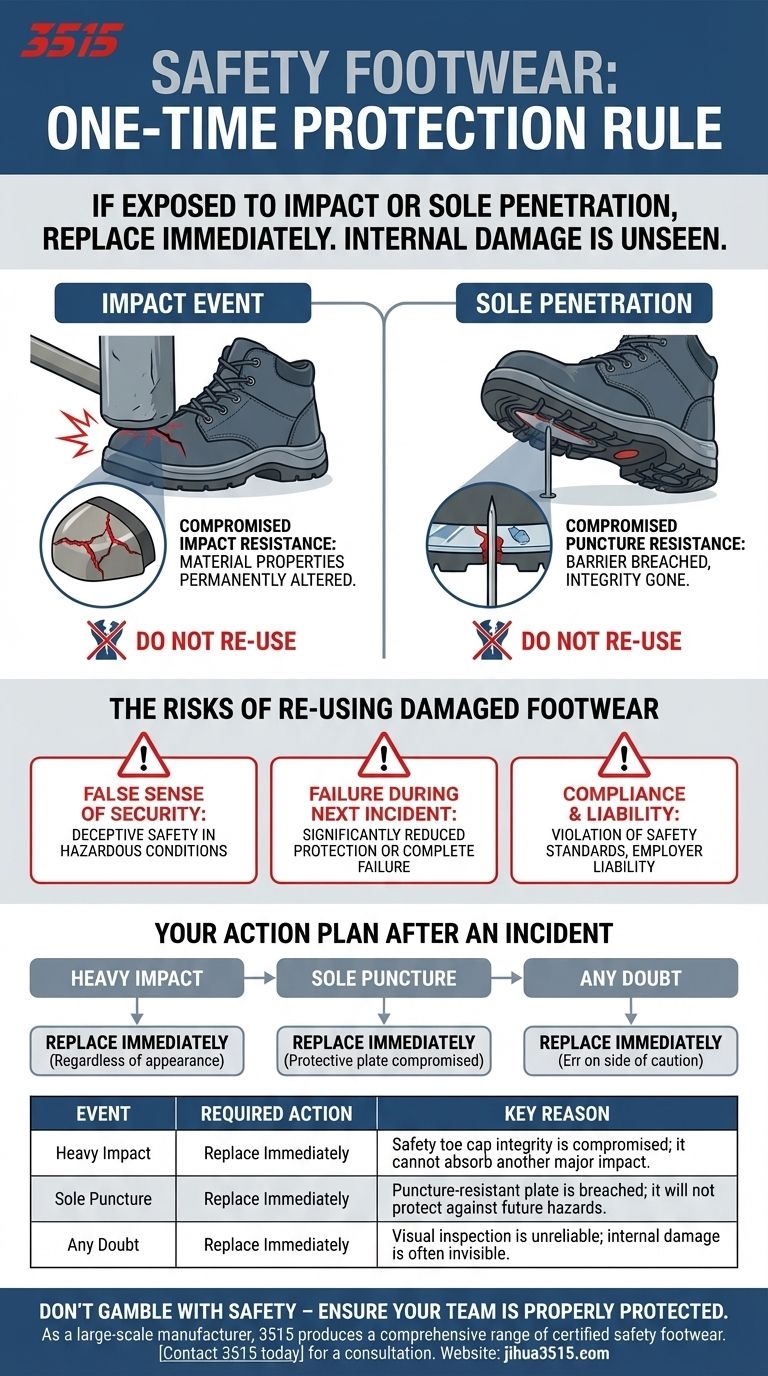

The definitive rule is clear: If your safety footwear is exposed to a significant impact or a sole penetration event, it must be replaced immediately. This is because the internal protective components, such as the safety toe or puncture-resistant plate, can sustain critical, unseen damage that renders them ineffective for future incidents.

The core principle to understand is that safety footwear is designed for a single, critical failure event. After it has protected you once from a serious impact or puncture, its structural integrity is compromised, and it cannot be trusted to provide the same level of protection again.

The Principle of "One-Time" Protection

Safety footwear is engineered personal protective equipment (PPE). Its ability to protect you depends on specific materials and structures remaining in their original, uncompromised state. A single event can permanently change them.

Why Visual Inspection Fails

The most dangerous assumption is that if a boot or shoe looks fine on the outside, it is safe to wear.

Internal damage, such as micro-fractures in a composite toe or a permanent deformation in a steel toe, is often completely hidden. A visual check cannot assess the remaining structural capacity of these critical components.

Compromised Impact Resistance

The safety toe cap (whether steel, alloy, or composite) is designed to absorb and deflect the energy of a major impact.

Once it has been crushed, dented, or struck with significant force, its material properties are permanently altered. It has already absorbed the energy it was designed to handle and will not perform to its certified standard a second time.

Compromised Puncture Resistance

Similarly, the puncture-resistant plate in the sole is a barrier. If a nail or other sharp object penetrates it, that barrier has been breached.

Even if the object is removed, the hole remains, creating a direct and unprotected path for any future hazards. The plate's integrity is gone.

The Risks of Re-Using Damaged Footwear

Continuing to use footwear after an incident is not a calculated risk; it is an unprotected gamble. The potential consequences far outweigh the cost of a new pair.

The False Sense of Security

The greatest danger is believing you are protected when you are not. Wearing compromised safety footwear provides a deceptive sense of safety, leading you to work in hazardous conditions without the actual protection you rely on.

Failure During the Next Incident

Footwear that has already sustained a major impact will offer significantly reduced protection—or fail completely—when faced with another one. A dented toe cap may collapse under a much lighter load than it was originally rated for.

Compliance and Liability

From a workplace safety perspective, knowingly using damaged PPE is a serious violation of safety standards. It places the worker in immediate danger and creates significant liability for the employer.

Your Action Plan After an Incident

Your response should be immediate and decisive, with no room for ambiguity. Safety is the only priority.

- If your footwear sustains a heavy impact: Immediately remove the footwear from service and replace it, regardless of its outward appearance.

- If the sole of your footwear is punctured: The protective plate has been compromised, and the footwear must be replaced without exception.

- If you are ever in doubt about an incident's severity: Always err on the side of caution and replace the footwear to guarantee your continued protection.

Ultimately, your safety footwear is a critical investment in your personal well-being, and its integrity must be absolute.

Summary Table:

| Event | Required Action | Key Reason |

|---|---|---|

| Heavy Impact | Replace Immediately | Safety toe cap integrity is compromised; it cannot absorb another major impact. |

| Sole Puncture | Replace Immediately | Puncture-resistant plate is breached; it will not protect against future hazards. |

| Any Doubt | Replace Immediately | Visual inspection is unreliable; internal damage is often invisible. |

Don't Gamble with Safety – Ensure Your Team is Properly Protected

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots designed to meet the highest safety standards.

Ensure your workforce has reliable, uncompromised protection. Let us help you source or create the perfect safety footwear solution for your needs.

Contact 3515 today for a consultation and secure your supply of trustworthy safety footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What primary function does specialized safety footwear serve in a CSSD? Expert Guide to Biological Barriers

- What are the different protection levels for safety footwear? A Guide to S1, S3 & More

- What role do professional safety shoes play in gemstone mining? Essential Protection for High-Altitude & Complex Terrain

- How is human joint motion monitoring technology applied to the research and development of safety shoes? Design Insights

- When did the development of safety footwear begin and what drove its introduction? The Industrial Revolution's Impact on Worker Safety

- Do safety boots expire? Understand Their True Service Life for Maximum Protection

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How does the slip resistance of safety shoe outsoles contribute to worker safety in limestone mining dumping areas?