When selecting a work boot, your decision must be guided by three core principles: the specific safety requirements of your job, the anatomical fit for your foot, and the quality of the boot's construction. These elements work together to provide protection, support, and durability for demanding tasks.

The ideal work boot is not the one with the most features, but the one with the right features for your specific work environment. Prioritizing a precise fit and job-specific protection will prevent long-term discomfort and serious injury.

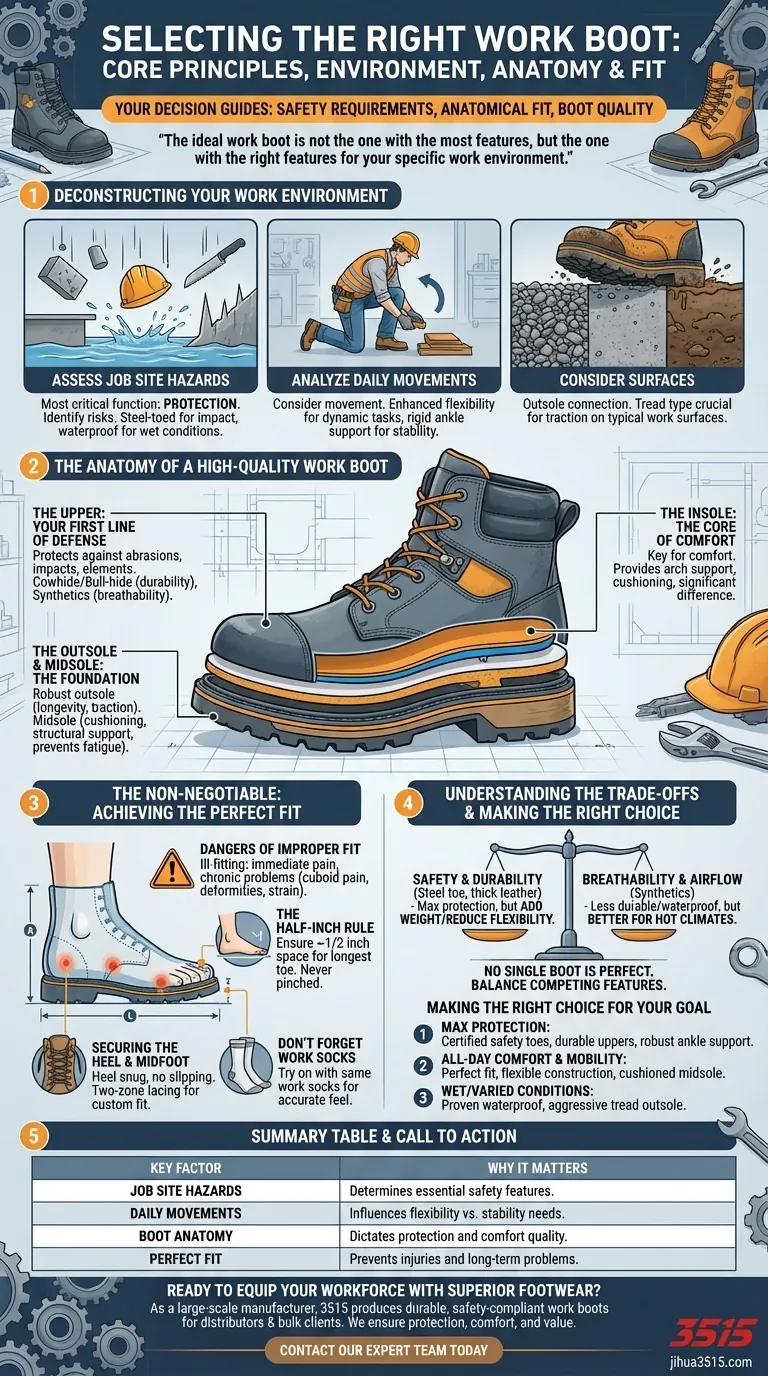

Deconstructing Your Work Environment

Before you even look at a boot, you must first analyze the conditions you face every day. The environment dictates the features you need.

Assess Your Job Site Hazards

The most critical function of a work boot is protection. Identify the primary risks at your worksite, such as falling objects or wet surfaces, to determine your non-negotiable safety features.

Most demanding jobs require steel-toed boots for impact protection. Likewise, if you frequently work in wet conditions, waterproof functionality is essential to prevent discomfort and foot issues.

Analyze Your Daily Movements

Consider the type of movement your job demands. A role requiring constant kneeling and quick pivots has different needs than one that involves standing on hard surfaces for hours.

Boots designed with enhanced flexibility are better for dynamic movement, while boots with more rigid ankle support are suited for stability on uneven terrain.

Consider the Surfaces You Walk On

The bottom of the boot, the outsole, is your connection to the ground. Its design is crucial for safety and stability.

The outsole tread type should match your typical work surface, whether it's loose gravel, slick concrete, or muddy ground.

The Anatomy of a High-Quality Work Boot

Understanding a boot's components empowers you to judge its quality and suitability for your needs.

The Upper: Your First Line of Defense

The upper is the material that covers your foot. It protects against abrasions, impacts, and the elements.

Materials like thick cowhide or bull-hide leather offer exceptional durability, while some synthetic fabrics provide better breathability or flexibility.

The Outsole and Midsole: The Foundation

The outsole contacts the ground, while the midsole sits above it to provide cushioning and absorb shock.

A robust outsole ensures longevity and traction, while a well-designed midsole provides the structural support that prevents foot fatigue over long shifts.

The Insole: The Core of Comfort

The insole is the removable layer your foot rests on inside the boot.

It is a key component for comfort, providing arch support and cushioning. A quality insole can make a significant difference in how your feet feel at the end of the day.

The Non-Negotiable: Achieving the Perfect Fit

An ill-fitting boot is more than just uncomfortable—it's a direct threat to your health and safety.

The Dangers of an Improper Fit

Poorly sized boots can cause immediate issues like blisters and pain, but they can also lead to chronic problems like cuboid pain, deformities, and musculoskeletal strain that impacts your entire body.

The Half-Inch Rule for Toe Room

When trying on boots, ensure there is about a half-inch of space between your longest toe and the front of the boot. Your toes should never feel pinched or cramped.

Securing the Heel and Midfoot

While your toes need room to move, your heel should fit snugly and not slip up and down as you walk. Features like two-zone lacing allow for a more customized and secure fit across the foot.

Don't Forget Your Work Socks

Always try on new boots while wearing the same type of socks you use for work. This ensures the most accurate assessment of the boot's true size and feel.

Understanding the Trade-offs

No single boot is perfect for every situation. Choosing the right one often involves balancing competing features.

Safety vs. Weight and Flexibility

Features like steel toes and thick leather offer maximum protection but add significant weight and can reduce flexibility, potentially causing fatigue over a long day.

Durability vs. Breathability

Heavy-duty materials like bull-hide leather are incredibly durable but can be less breathable than synthetic options, which may be important in hot climates.

Waterproofing vs. Airflow

A fully waterproof boot is excellent for keeping water out, but the membrane that accomplishes this can also trap sweat, making it less ideal for hot, dry environments.

Making the Right Choice for Your Goal

Select your boot by prioritizing the features that solve your most pressing daily challenges.

- If your primary focus is maximum protection: Prioritize boots with certified safety toes, durable leather uppers, and robust ankle support.

- If your primary focus is all-day comfort and mobility: Emphasize a perfect fit, a flexible construction, and a high-quality cushioned midsole.

- If your primary focus is working in wet or varied conditions: Look for proven waterproof functionality and an outsole with an aggressive tread pattern for superior traction.

Investing the time to choose the right work boot is an investment in your daily comfort, safety, and long-term health.

Summary Table:

| Key Selection Factor | Why It Matters |

|---|---|

| Job Site Hazards | Determines essential safety features like steel toes or waterproofing. |

| Daily Movements | Influences the need for flexibility versus stability and ankle support. |

| Boot Anatomy | Quality of the upper, outsole, midsole, and insole dictates protection and comfort. |

| Perfect Fit | Prevents injuries and long-term foot problems; follow the half-inch toe room rule. |

Ready to Equip Your Workforce with Superior Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of occupational footwear, ensuring the perfect combination of protection, comfort, and value for your specific needs.

Contact our expert team today to discuss your requirements and discover how we can support your business with high-quality, reliable footwear solutions.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What were the original purposes of cowboy boots? A Tool for Safety and Function on the Range

- What are the limitations of pull-on work boots? A Guide to Choosing for Safety & Support

- How can one choose the right size for motorcycle boots? Secure the Perfect Fit for Safety and Control

- Why are wide toe boxes important in work boots? Boost Stability & Prevent Foot Pain

- What are the key benefits of high-quality work boots? Unlock Safety, Comfort & Long-Term Value

- What are the alternatives to work boots for women? Find the Perfect Fit for Your Job

- Why are moisture-wicking and breathable linings necessary for Work Boots? Optimize Heat Management and Foot Health

- What is the significance of safety training with safety boots? Maximizing Protection in High-Risk Zones