To choose the right material for work boots, you must first analyze your work environment and then match it to the specific properties of the available materials, primarily leather, rubber, and modern synthetics. The ideal choice is a direct response to your daily needs for durability, protection, waterproofing, and all-day comfort.

The most common mistake is searching for a single "best" material. The correct approach is to view the boot as a system, where the primary material is chosen to solve the biggest problem your specific job presents—be it impact, water, or long hours on your feet.

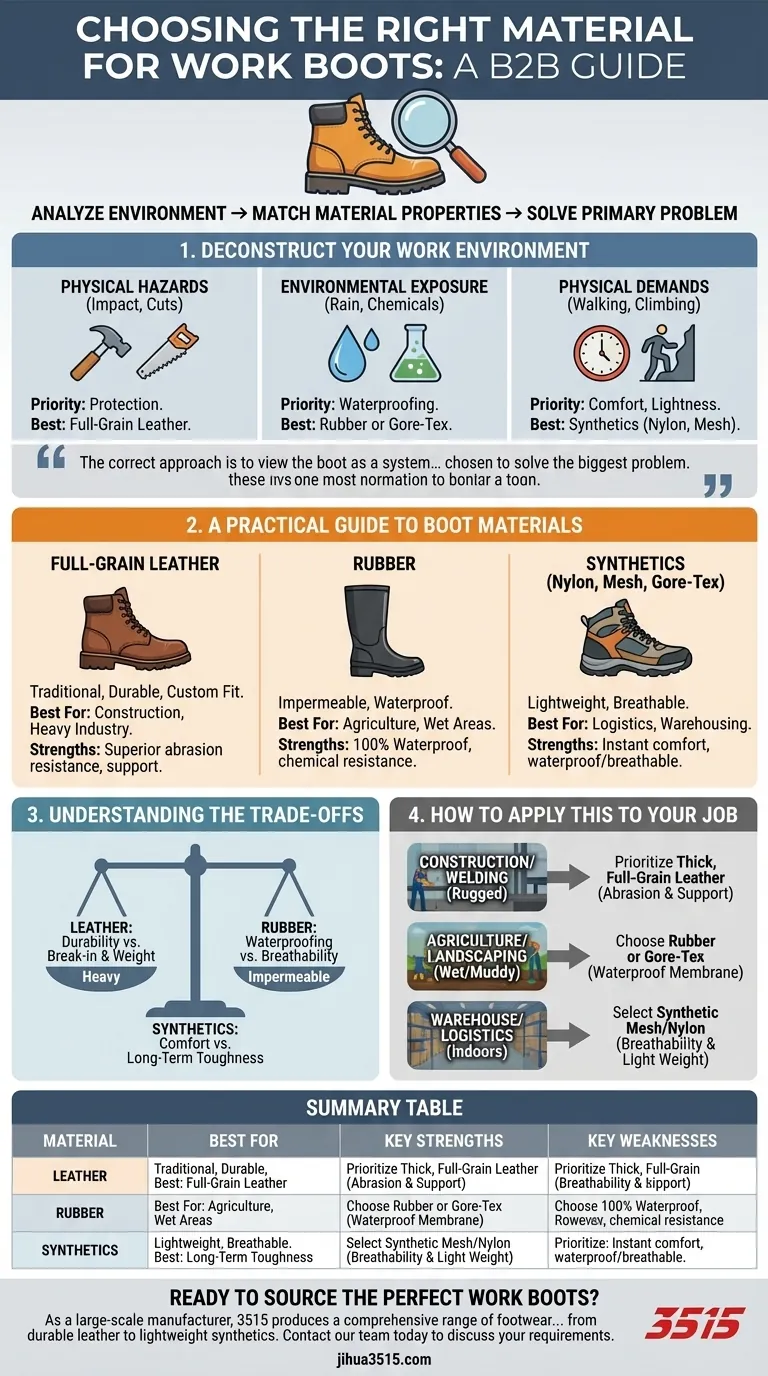

Deconstruct Your Work Environment

Before you can evaluate a material, you must have a clear picture of the demands you will place on it. Your job site is the ultimate test.

Assessing Physical Hazards

The most immediate priority is protection from impact, compression, and punctures. While safety toes are a separate feature, the upper material provides the first line of defense.

Heavy-duty, full-grain leather offers excellent resistance to abrasion and cuts, which is critical in construction, manufacturing, or forestry.

Evaluating Environmental Exposure

Consider the elements you face daily. Are you working in rain, mud, snow, or around chemicals?

Rubber is the definitive choice for 100% waterproof protection in standing water or chemical-heavy areas. For environments that are wet but also require breathability, a waterproof membrane like Gore-Tex integrated into leather or synthetic boots is a superior option.

Analyzing Physical Demands

How much do you walk, stand, or climb? The weight and flexibility of your boot material directly impact fatigue over an 8- to 12-hour shift.

Lighter synthetic materials like nylon or mesh panels reduce weight and increase breathability, making them ideal for logistics, warehouse work, or light manufacturing where mobility is key.

A Practical Guide to Boot Materials

Each material offers a distinct combination of benefits. Understanding these core identities is key to making an informed choice.

Full-Grain Leather

This is the traditional and often most durable option. It's a natural material that conforms to your foot over time, offering a custom fit.

Leather is highly resistant to abrasion and provides excellent support, making it the standard for demanding jobs in construction and heavy industry.

Rubber

When dealing with constant exposure to water, mud, or certain chemicals, nothing surpasses rubber. It provides a completely impermeable barrier.

These boots are essential for agriculture, fishing, and concrete work, but their lack of breathability makes them unsuitable for dry, hot conditions.

Synthetics (Nylon, Mesh, Gore-Tex)

This broad category includes materials engineered for specific performance traits. Nylon and mesh panels are used to reduce weight and dramatically increase breathability.

High-tech membranes like Gore-Tex are laminated into the boot's construction, offering the unique advantage of being both waterproof from the outside and breathable from the inside.

Understanding the Trade-offs

No single material is perfect for every situation. Being aware of the inherent compromises is critical for selecting the right boot.

Leather: Durability vs. Break-in and Weight

While incredibly tough, high-quality leather boots require a break-in period and can be heavy, which may contribute to fatigue. They also require regular maintenance to preserve their water resistance and flexibility.

Rubber: Waterproofing vs. Breathability

Rubber's greatest strength is also its main weakness. By keeping all water out, it also traps all sweat in, which can lead to discomfort and skin issues in warm weather or during strenuous activity.

Synthetics: Comfort vs. Long-Term Toughness

Synthetics offer instant comfort and are lightweight, but they generally do not offer the same long-term abrasion resistance as a thick leather hide. A boot with many seams and synthetic panels may have more potential failure points than a simple, full-grain leather design.

How to Apply This to Your Job

Use your primary daily challenge as your guide. Your goal is to choose the material that best solves that specific problem.

- If your primary focus is durability in a rugged environment (construction, welding): Prioritize a boot made from thick, full-grain leather for its superior abrasion resistance and support.

- If your primary focus is working in consistently wet or muddy conditions (agriculture, landscaping): Choose a rubber boot or a leather/synthetic boot with a certified waterproof membrane like Gore-Tex.

- If your primary focus is mobility and all-day comfort indoors (warehouse, logistics): Select a lighter boot featuring synthetic mesh or nylon panels for maximum breathability and reduced weight.

Ultimately, the right material is the one that allows you to focus on your work, not your feet.

Summary Table:

| Material | Best For | Key Strengths | Key Weaknesses |

|---|---|---|---|

| Full-Grain Leather | Construction, Heavy Industry | Superior abrasion resistance, durability, support | Requires break-in, heavier, needs maintenance |

| Rubber | Agriculture, Wet/Chemical Areas | 100% waterproof, chemical resistance | Poor breathability, can be hot |

| Synthetics (Nylon, Gore-Tex) | Warehousing, Logistics | Lightweight, breathable, waterproof/breathable membranes | Less abrasion resistance than leather |

Ready to source the perfect work boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We understand that the right material is critical for safety and productivity. Our production capabilities encompass all types of shoes and boots, from durable leather for heavy industry to lightweight synthetics for logistics.

Let us help you provide your workforce with boots that are built for their specific job demands. Contact our team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What types of safety toes are available in mining boots? Choose the Right Protection for Your Mine

- How do orthotic insoles improve work boot comfort? Achieve All-Day Support and Reduce Fatigue

- What other workplace hazards are denoted on safety toe boots? Decode the EH, Mt, and SD markings.

- How are work boot insulation ratings measured? A Guide to Choosing the Right Warmth

- Why is conditioning or oiling leather work boots important? Prevent Cracking & Extend Boot Life

- What are the main purposes of safety labels on work boots? A Guide to Choosing the Right PPE

- What is the conclusion about using cowboy boots for farm work? A Guide to Choosing the Right Boot

- What are the benefits of wearing bamboo socks with work boots? Maximize Comfort & Foot Health