Alright, here's the plan. I'm taking on this Senior Technical Advisor role and need to help this user, an expert like myself, make a crucial decision: choosing between steel and composite toe boots. My strategy is to address both their immediate question and the underlying need to stay safe and comfortable in their specific work environment. I'll be drawing on my expertise and the provided information, but I'll focus like a laser on the critical points of steel versus composite safety boots. I'm going to discard all the irrelevant details about other boot types and fashion trends, and just get straight to the point. I will structure the information for easy scanning with bolding and concise paragraphs, making sure to hit the key trade-offs and provide actionable advice. The choice between composite-toe and steel-toe boots is a critical safety decision. While both are designed to protect your feet from impact and compression, they achieve this with different materials that have distinct advantages. Steel toes offer the absolute maximum strength against crushing forces, whereas composite toes provide a modern, lightweight alternative better suited for environments with electrical hazards or extreme temperatures.

Your decision should not be based on which material is inherently "better," but which is superior for your specific set of daily hazards and environmental conditions. Both must meet the same baseline safety standards, but their material properties make them ideal for different jobs.

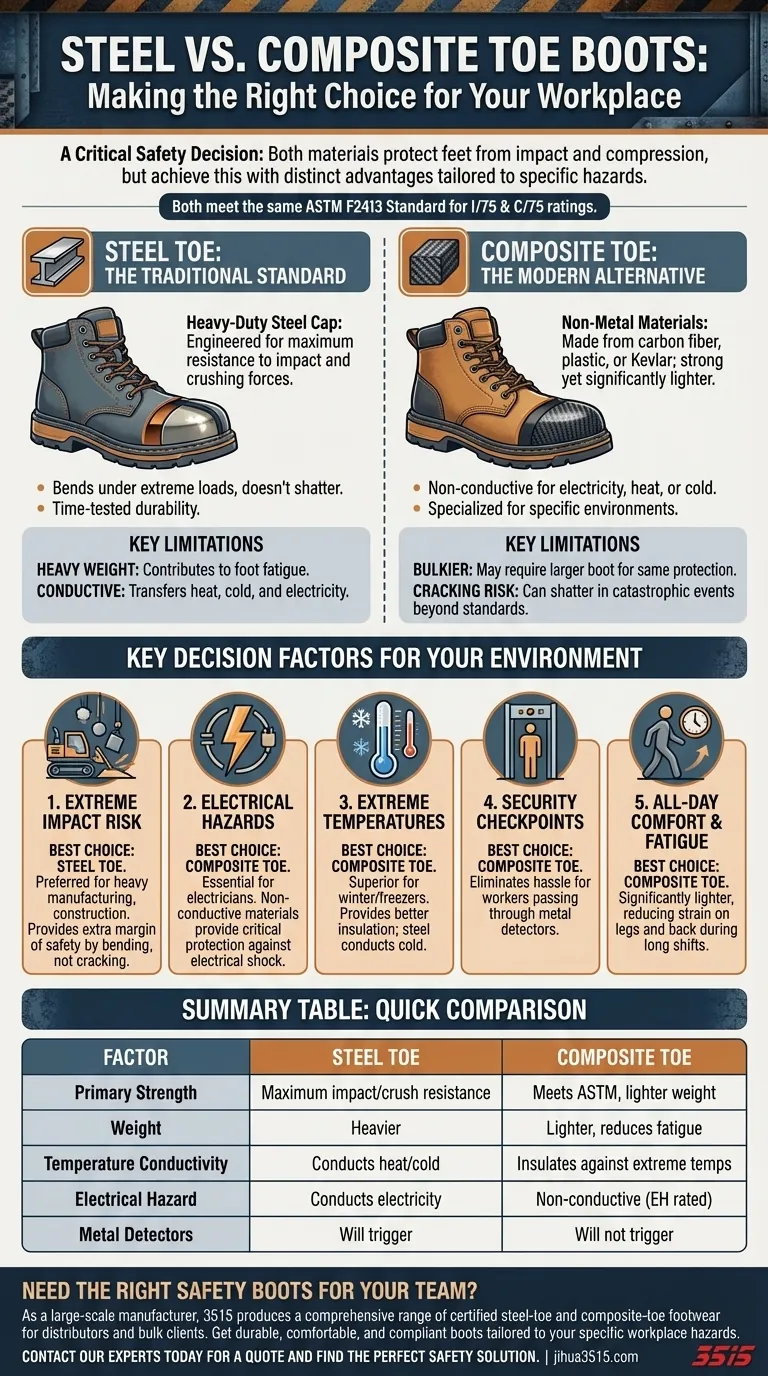

Deconstructing the Safety Toe: Steel vs. Composite

To make an informed choice, you must first understand the fundamental differences in material and construction. The right option becomes clear when you align these properties with your workplace demands.

The Steel Toe Standard

A steel toe is the traditional form of protection. It's a heavy-duty steel cap integrated into the boot that is engineered for maximum resistance to impact and compression.

This time-tested technology is renowned for its durability and its ability to bend and deform under extreme loads without shattering.

The Composite Toe Alternative

A composite toe is made from non-metal materials, such as carbon fiber, plastic, or Kevlar. These materials are engineered to be strong yet significantly lighter than steel.

The primary advantage of composite materials is that they do not conduct electricity, heat, or cold, making them a specialized solution for certain work environments.

The ASTM Standard: A Level Playing Field

It is crucial to understand that in the United States, both steel and composite safety toes must meet the same ASTM F2413 standard for impact and compression resistance (rated I/75 and C/75). This ensures that any compliant boot provides a certified level of protection, regardless of the toe material.

Key Decision Factors for Your Environment

Your specific workplace is the most important variable in this decision. Analyzing your daily tasks and potential hazards will point you directly to the right boot.

Factor 1: Extreme Impact Risk

If you work around heavy machinery, falling objects, or have a high risk of crushing incidents (e.g., heavy manufacturing, logging, construction), steel toes are often the preferred choice. Their ability to bend rather than crack under loads that exceed safety standards provides an extra margin of safety.

Factor 2: Electrical Hazards

For electricians or anyone working near live circuits, composite-toe boots are the only logical option. Because they are made of non-conductive materials, they provide a critical layer of protection against electrical shock.

Factor 3: Extreme Temperatures

If you work outdoors in the winter or inside commercial freezers, a steel toe will conduct the cold directly to your foot. Composite toes are far superior in these conditions, as they provide better insulation and help keep your feet warmer.

Factor 4: Security Checkpoints

For workers who must frequently pass through metal detectors, such as in airports, secure facilities, or government buildings, composite toes eliminate a significant daily hassle.

Factor 5: All-Day Comfort and Fatigue

Weight is a major factor in foot fatigue over a long shift. Because composite toes are significantly lighter than steel, they can reduce the strain on your legs and back, making them an excellent choice for workers who are constantly on the move.

Understanding the Trade-offs

Neither option is perfect for every situation. Being aware of the limitations of each material is key to avoiding a poor choice.

The Limits of Steel Toes

The primary disadvantages of steel are its weight, which contributes to fatigue, and its conductivity. Steel readily transfers both heat and cold, and it will conduct electricity, making it unsuitable for certain hazardous jobs.

The Limits of Composite Toes

Composite toes are generally bulkier than steel toes to achieve the same level of impact resistance. While they meet ASTM standards, in a catastrophic event that far exceeds those standards, they are more likely to crack or shatter, whereas steel is more likely to bend.

Making the Right Choice for Your Goal

Select your boot by prioritizing the single most important factor for your job.

- If your primary focus is maximum impact resistance: Choose steel-toe boots for their proven strength in environments with extreme crushing hazards.

- If your primary focus is lightweight comfort: Choose composite-toe boots to reduce foot and leg fatigue during long shifts with lots of walking.

- If your primary focus is working in extreme cold: Choose composite-toe boots for their superior thermal insulation that keeps your feet warmer.

- If your primary focus is electrical hazard (EH) protection: You must choose a properly rated composite-toe boot for its non-conductive properties.

By matching the boot's material properties to your daily work hazards, you ensure both regulatory compliance and optimal personal safety.

Summary Table:

| Factor | Steel Toe | Composite Toe |

|---|---|---|

| Primary Strength | Maximum impact/crush resistance | Meets ASTM standards, lighter weight |

| Weight | Heavier | Lighter, reduces fatigue |

| Temperature Conductivity | Conducts heat/cold | Insulates against extreme temperatures |

| Electrical Hazard | Conducts electricity | Non-conductive (EH rated) |

| Metal Detectors | Will trigger | Will not trigger |

Need the right safety boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of certified steel-toe and composite-toe footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you get durable, comfortable, and compliant boots tailored to your specific workplace hazards. Contact our experts today for a quote and find the perfect safety solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- How do steel toe shoes protect workers? The Ultimate Guide to Foot Safety

- What are the benefits of steel-toe boots in terms of impact resistance? Get Maximum Protection for Your Workforce

- Which industries commonly use steel toe boots? Essential Foot Protection for High-Risk Jobs

- How do alloy safety toes compare to steel toes? Lighter Weight, Equal Protection

- What are the drawbacks of steel toe boots? Weighing Protection Against Comfort

- What is the purpose of men's safety toe work boots? Complete Foot Protection for Hazardous Work

- What are the alternatives to steel toe boots for safety? Discover Lighter, Safer Options

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries