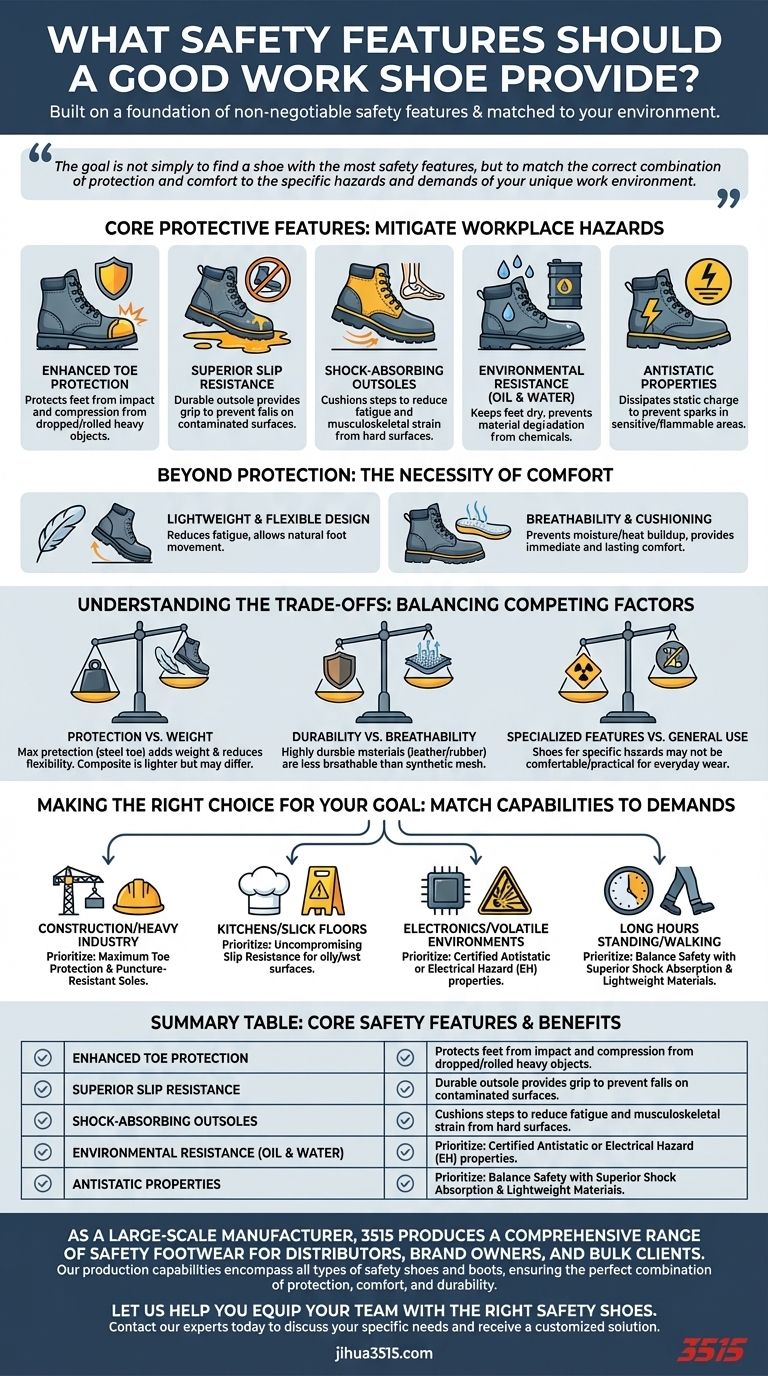

An effective work shoe is built on a foundation of non-negotiable safety features. These core protections include enhanced toe guards, superior slip resistance against slick surfaces, shock-absorbing outsoles, resistance to oil and water, and antistatic properties to prevent electrical discharge.

The goal is not simply to find a shoe with the most safety features, but to match the correct combination of protection and comfort to the specific hazards and demands of your unique work environment.

Core Protective Features Explained

The primary function of a work shoe is to mitigate workplace hazards. Each safety feature is engineered to counter a specific type of risk.

Enhanced Toe Protection

This is the most recognized safety feature, designed to protect your feet from impact and compression. It is essential in environments where heavy objects could be dropped or rolled onto the foot.

Superior Slip Resistance

The shoe's outsole must be made from durable materials that provide excellent grip. This is crucial for preventing falls on surfaces contaminated with water, oil, or other slippery substances.

Shock-Absorbing Outsoles

Standing or walking for long hours on hard surfaces places significant stress on your feet, joints, and back. A shock-absorbing sole cushions every step, reducing fatigue and the risk of musculoskeletal strain.

Environmental Resistance (Oil & Water)

Materials that resist oil and water serve two purposes. They keep your feet dry and comfortable while also preventing the shoe's materials from degrading prematurely due to chemical exposure.

Antistatic Properties

In environments with sensitive electronic equipment or flammable materials, static electricity can be a serious hazard. Antistatic shoes dissipate the body's static charge, preventing sparks that could damage components or cause ignition.

Beyond Protection: The Necessity of Comfort

A safe shoe that is too uncomfortable to wear properly is not truly safe. Modern work shoes integrate comfort features that are just as critical as the protective elements for all-day performance.

Lightweight and Flexible Design

Heavy, rigid boots can cause significant fatigue over a full workday. A good work shoe should be light and flexible, allowing for natural foot movement similar to an athletic shoe.

Breathability and Cushioning

A breathable upper material prevents moisture and heat buildup, which is vital for foot health. A soft, well-cushioned insole provides immediate and lasting comfort, especially for those who spend hours on their feet.

Understanding the Trade-offs

Choosing a work shoe always involves balancing competing factors. Understanding these trade-offs is key to making an informed decision.

Protection vs. Weight

Features like steel toe caps and puncture-resistant plates offer maximum protection but add significant weight and can reduce flexibility. Composite materials offer a lighter alternative but may have different protective ratings.

Durability vs. Breathability

Highly durable, waterproof materials like thick leather or rubber are excellent for harsh, wet environments. However, they are typically far less breathable than synthetic mesh, which can lead to discomfort in hot conditions.

Specialized Features vs. General Use

A shoe designed for a very specific hazard, such as electrical insulation or chemical handling, may not be comfortable or practical for general-purpose wear. Overspecialization can compromise everyday comfort.

Making the Right Choice for Your Goal

Select your footwear based on a clear analysis of your most common tasks and risks.

- If your primary focus is construction or heavy industry: Prioritize maximum toe protection and puncture-resistant soles to guard against impact and sharp objects.

- If your primary focus is working in kitchens or on slick floors: Uncompromising slip resistance for oily and wet surfaces is your most critical feature.

- If your primary focus is electronics assembly or volatile environments: Ensure your shoes have certified antistatic or electrical hazard (EH) properties.

- If your primary focus is long hours of standing or walking: Balance essential safety needs with features that maximize comfort, like superior shock absorption and lightweight materials.

By matching the shoe's capabilities to your workplace demands, you invest in both your immediate safety and your long-term well-being.

Summary Table:

| Core Safety Feature | Protects Against | Key Benefit |

|---|---|---|

| Enhanced Toe Protection | Impact from heavy objects | Prevents foot injuries |

| Superior Slip Resistance | Falls on oily/wet surfaces | Reduces slip and fall accidents |

| Shock-Absorbing Outsoles | Fatigue from hard surfaces | Lessens joint and back strain |

| Environmental Resistance | Water, oil, and chemicals | Increases durability and comfort |

| Antistatic Properties | Static electricity discharge | Prevents sparks in sensitive areas |

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the perfect combination of protection, comfort, and durability for your workforce.

Let us help you equip your team with the right safety shoes. Contact our experts today to discuss your specific needs and receive a customized solution.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What are the features of non-slip athletic sneakers? The Ultimate Guide to Traction & Performance

- How does the use of test plates with varying hardness and textures benefit the development of anti-slip footwear?

- How can one verify if shoes are truly slip-resistant? Look for the ASTM Certification Mark

- What should be considered when choosing non-slip shoes for the workplace? Select the Right Safety Footwear

- What is the primary role of anti-slip safety shoes in palm oil mill boiler stations? Ensure Worker Safety & Stability

- What is the cost consideration when choosing between slip-resistant shoes and everyday sneakers? Avoid the False Economy

- What are the requirements for a genuine slip-resistant shoe? Key Features for Ultimate Safety

- What types of slip-resistant shoes are available for women? Find the Perfect Fit for Safety & Style