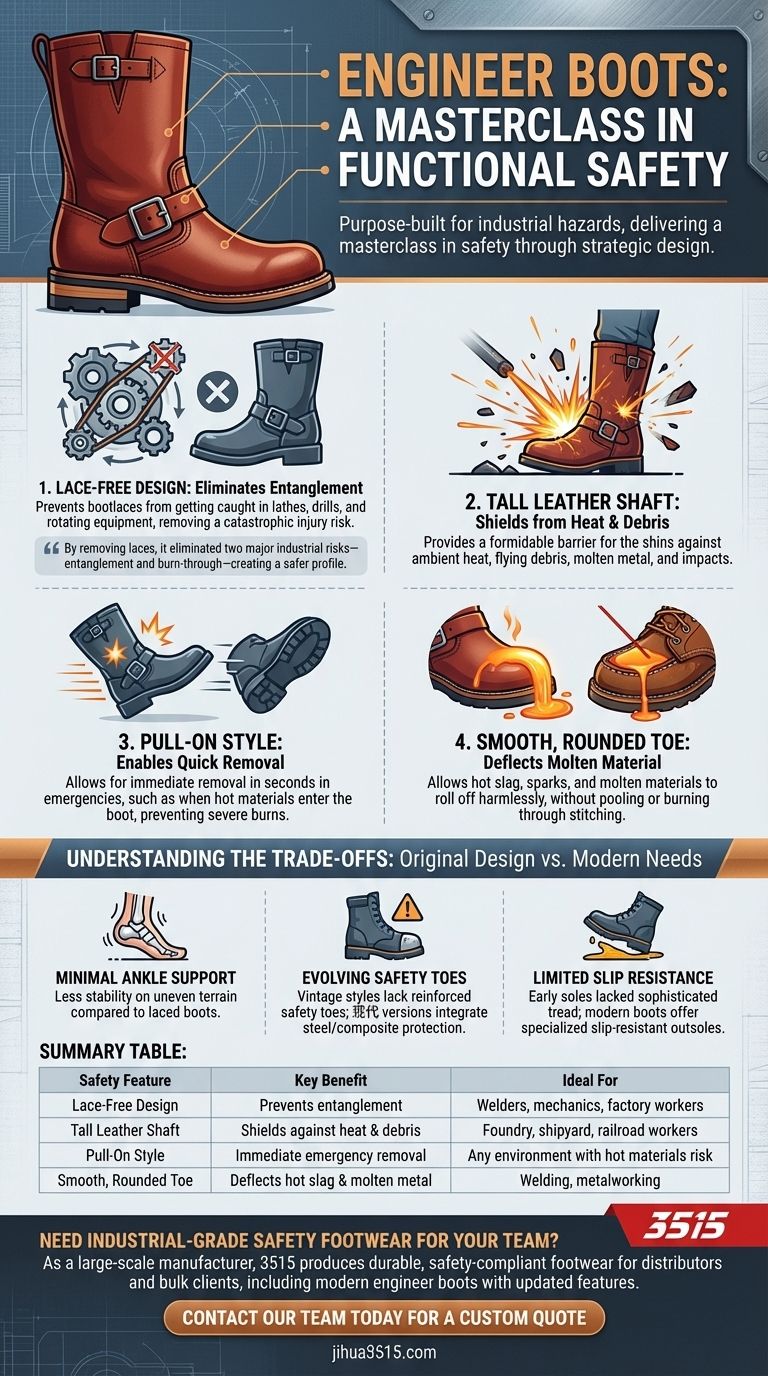

Engineer boots delivered a masterclass in functional safety, purpose-built for the specific hazards of industrial work. Their core protective features were a lace-free design to prevent entanglement in machinery, a tall leather shaft to guard against heat and debris, and a pull-on style that allowed for immediate removal in emergencies, such as when hot sparks entered the boot.

The genius of the engineer boot's design is not just what it includes, but what it strategically omits. By removing laces, it eliminated two major industrial risks—entanglement and burn-through—creating a safer profile for workers around heavy machinery and extreme heat.

A Design Forged by Industrial Hazards

The engineer boot was not an aesthetic choice; it was a direct solution to the daily dangers faced by railroad firemen, welders, and factory workers in the early 20th century. Each feature addressed a specific, common risk.

Eliminating Entanglement Risk

The most critical feature of the engineer boot is its lace-free construction.

Workers operating lathes, drills, and other equipment with rotating parts faced the constant danger of a bootlace getting caught, which could lead to catastrophic injury. The engineer boot’s simple buckle-and-strap system secured the foot without creating this hazard.

Deflecting Heat and Molten Metal

The boot’s silhouette was a key defensive feature against burns.

Its smooth, rounded toe allowed hot slag, sparks, and other molten materials to roll off harmlessly. This contrasts sharply with moc-toe or stitched designs, which can create ledges where hazardous material could pool and burn through the leather. The absence of eyelets and laces also removed common points of failure where sparks could ignite material or burn through to the skin.

The Critical Need for Quick Removal

In environments like shipyards and foundries, a spark or piece of hot metal falling inside a boot was a serious emergency.

The engineer boot's wide shaft and pull-on design were life-savers. A worker could kick the boot off in seconds to prevent a severe burn, a feat that would be impossible with a tightly laced-up boot.

Robust Shaft and Upper Protection

The tall, often double-layered leather shaft provided a formidable barrier.

This shielded the wearer's shins from ambient heat, flying debris, water, and impact. It created a durable guard that protected a significant portion of the lower leg from the unpredictable dangers of an industrial site.

Understanding the Trade-offs

While revolutionary for its intended purpose, the original design of the engineer boot presents trade-offs when measured against modern, specialized work boots.

The Absence of Ankle Support

The pull-on style, while excellent for quick removal, offers minimal ankle lockdown.

Compared to a tightly laced 8-inch boot, the engineer boot provides less stability. This makes it a less ideal choice for workers who regularly traverse highly uneven terrain or require significant ankle support to prevent sprains.

The Evolution to Safety Toes

Original engineer boots did not typically feature the reinforced safety toes that are now standard in most industrial footwear.

Protection against crushing injuries from falling objects came later with the integration of steel and composite toes. A vintage-style boot may not offer this critical modern protection.

Limited Slip Resistance

Early boot soles were often made of simple leather or rubber compounds that lacked the sophisticated tread patterns of today.

Modern industrial boots place a heavy emphasis on specialized, slip-resistant outsoles designed to grip oily, wet, or uneven surfaces—a feature that has been significantly improved upon since the engineer boot's inception.

Making the Right Choice for Your Hazard

To apply these principles, evaluate the primary risks of your environment.

- If your primary focus is avoiding entanglement or burns: The lace-free, pull-on design of an engineer boot remains a superior choice for welders, mechanics, and anyone working near rotating machinery.

- If your primary focus is impact from falling objects: Ensure you select a modern engineer boot that explicitly incorporates an ASTM-certified steel or composite safety toe.

- If your primary focus is stability on rough ground: A traditional lace-up work boot will provide the superior ankle support and stability needed for that environment.

Ultimately, understanding the specific purpose behind a boot's design empowers you to select the tool that truly keeps you safe.

Summary Table:

| Safety Feature | Key Benefit | Ideal For |

|---|---|---|

| Lace-Free Design | Prevents entanglement in machinery | Welders, mechanics, factory workers |

| Tall Leather Shaft | Shields against heat, sparks, and debris | Foundry, shipyard, and railroad workers |

| Pull-On Style | Allows for immediate removal in emergencies | Any environment with risk of hot materials entering boot |

| Smooth, Rounded Toe | Deflects hot slag and molten metal | Welding, metalworking |

Need industrial-grade safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, including modern engineer boots with updated safety features like steel toes and slip-resistant soles.

Let us help you equip your workforce with the right protective gear. Contact our team today for a custom quote and discover how we can meet your specific safety and bulk procurement needs.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How should work boots be cared for to ensure longevity? A 4-Step Guide to Maximize Durability

- Why are safety boots and chemical-resistant trousers vital for paddy fields? Protect Your Workers Today

- What are the recommended work boot features for the construction industry? Maximize Safety and Comfort

- What are the uses of fire boots? The Ultimate Guide to Foot Protection for Firefighters

- What features should workers on slick floors look for in work boots? Maximize Safety & Stability

- What are the five most important components of boot fitting? A Guide to Perfect Fit & Performance

- How do custom or aftermarket insoles function? Master Protective Boot Fit and Stability for Enhanced Performance

- How to choose the right work boot? Match Safety Features to Your Job's Hazards