The most critical safety feature for boots intended for electrical work is an official Electrical Hazard (EH) rating. This certification ensures the footwear has non-conductive soles and heels that can withstand the application of 18,000 volts at 60 Hz for one minute with no current flow. This is complemented by other essential features like non-conductive composite safety toes and slip-resistant outsoles.

The core challenge isn't just finding a boot with an EH rating, but understanding the fundamental difference between protection from electric shock and protection from static discharge. These are two distinct and opposing types of safety, and choosing the wrong one for your environment can be a critical mistake.

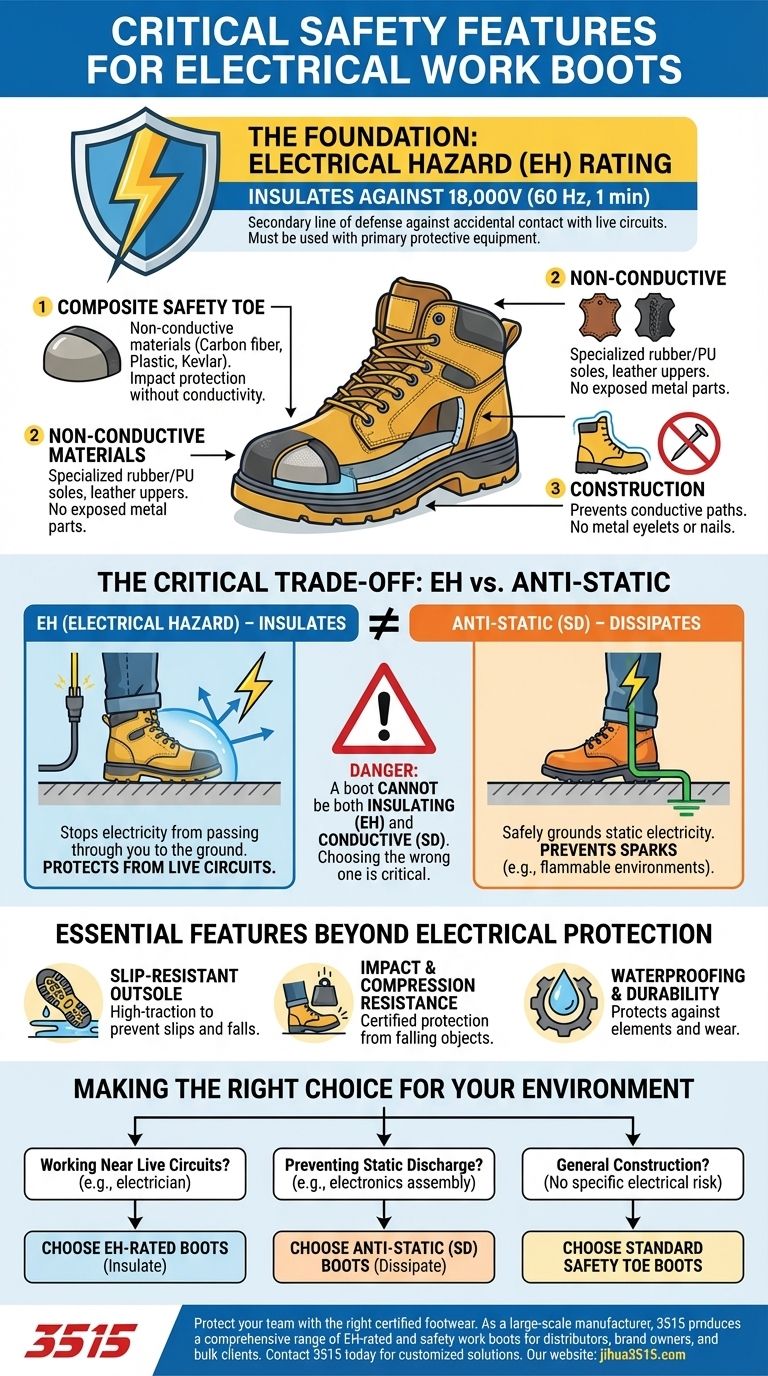

The Foundation: The Electrical Hazard (EH) Rating

An EH-rated boot is your secondary line of defense against accidental contact with live electrical circuits. It is designed to insulate you from the ground, thereby impeding the path for electricity to travel through your body.

What the EH Rating Certifies

To earn an EH rating, a boot must pass a rigorous test defined by safety standards. The footwear must resist a current of 18,000 volts for a full minute, proving its insulating properties.

A Secondary Source of Protection

It is crucial to understand that EH-rated footwear is considered a supplemental or secondary source of protection. It should always be used in conjunction with primary protective equipment like insulated gloves, blankets, and proper safety protocols.

Deconstructing the Non-Conductive Boot

Several design elements work together to achieve the EH rating and provide comprehensive protection from electrical shock.

Non-Conductive Materials

The primary materials used in EH boots are inherently non-conductive. This typically includes leather for the uppers and specialized rubber or polyurethane compounds for the soles.

Composite vs. Steel Toes

While steel toes offer excellent impact protection, they are conductive. For this reason, EH-rated boots almost exclusively use composite safety toes made from materials like carbon fiber, plastic, or Kevlar to prevent creating an accidental path for electricity.

Insulated and Sealed Construction

The boot's construction is just as important as its materials. EH footwear is built without any exposed conductive components, such as nails or metal eyelets, that could compromise its insulating capability.

Understanding the Critical Trade-off: EH vs. Anti-Static

The most common point of confusion—and danger—is failing to distinguish between non-conductive and anti-static boots. They serve opposite functions.

The Role of Non-Conductive (EH) Boots

As discussed, EH boots insulate you. Their purpose is to stop electricity from passing through you to the ground, protecting you from live circuits.

The Role of Anti-Static (SD) Boots

Anti-Static, or Static Dissipative (SD), boots do the exact opposite. They are designed to safely dissipate the body's static electricity into the floor. This prevents sparks that could ignite flammable materials or damage sensitive electronic components.

Why You Can't Have Both

A single boot cannot be both insulating (EH) and conductive (SD). You are either isolated from the ground or connected to it. Using an SD boot while working on live circuits would be extremely dangerous, as it would facilitate the flow of electricity through your body.

Essential Features Beyond Electrical Protection

While the EH rating is paramount, a good work boot must also meet broader safety standards to be effective on a job site.

Slip-Resistant Outsoles

Preventing slips, trips, and falls is a universal safety requirement. A high-traction, slip-resistant outsole is a non-negotiable feature for any work environment.

Impact and Compression Resistance

The composite toe must not only be non-conductive but also meet certified standards for protecting your feet from falling objects and compression hazards.

Waterproofing and Durability

For those working outdoors or in industrial settings, waterproofing protects against the elements, while durable construction ensures the boot's safety features do not degrade prematurely with wear and tear.

Making the Right Choice for Your Environment

Your specific job function and work environment dictate the necessary protection.

- If your primary focus is working near live circuits (e.g., electrician, utility lineman): You require boots with an Electrical Hazard (EH) rating to provide insulation against shock.

- If your primary focus is preventing static discharge (e.g., electronics assembly, working near flammable vapors): You need Anti-Static (SD) or Static Dissipative footwear to ground you.

- If your primary focus is general construction with no specific electrical risk: A standard safety toe boot (steel or composite) with good slip resistance is sufficient.

Choosing the correct, certified boot for your specific hazard is a foundational step in ensuring your personal safety on the job.

Summary Table:

| Critical Safety Feature | Purpose & Key Detail |

|---|---|

| Electrical Hazard (EH) Rating | Insulates the wearer; secondary protection against live circuits (18,000V test). |

| Non-Conductive Composite Toe | Protects from impact without conducting electricity (unlike steel toes). |

| Slip-Resistant Outsole | Prevents slips and falls on the job site. |

| Insulated & Sealed Construction | Prevents any conductive components from compromising safety. |

| EH vs. Anti-Static (SD) | EH insulates from shock; SD dissipates static to prevent sparks. A boot cannot be both. |

Protect your team with the right certified footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated and safety work boots for distributors, brand owners, and bulk clients. Our expertise ensures your workforce has the correct, certified protection for their specific electrical hazards, combining critical safety features with durable, comfortable designs.

Contact 3515 today to discuss your safety footwear needs and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What are examples of NFPA-approved wildland firefighting boots? Wildlander vs. Linecutter II Compared

- What safety standards should oilfield work boots meet? Ensure OSHA & ASTM F2413 Compliance

- What should women consider if they must buy men's work boots? A Guide to Fit, Safety & Compromise

- What features are important for plumbers in work boots? The Ultimate Guide to Safety & Performance

- What factors should be considered when choosing wildfire boots? A Guide to NFPA-Certified Safety & Performance

- What materials are modern Wellington work boots made from? A Guide to Durability & Waterproofing

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection

- Can water-resistant boots be submerged in water? Understand the critical difference for dry feet.