At its core, innovation in oil field boots is the driving force that transforms them from simple footwear into critical personal protective equipment. This evolution is achieved through the integration of high-tech materials, advanced structural designs, and modern safety components like composite toe caps, all engineered to enhance safety, comfort, and durability in one of the world's most demanding work environments.

The central purpose of innovation in this field is not merely to create a better boot, but to directly address and mitigate the specific, high-stakes risks faced by workers every day. It's about reducing fatigue, preventing injury, and improving performance through applied material science and engineering.

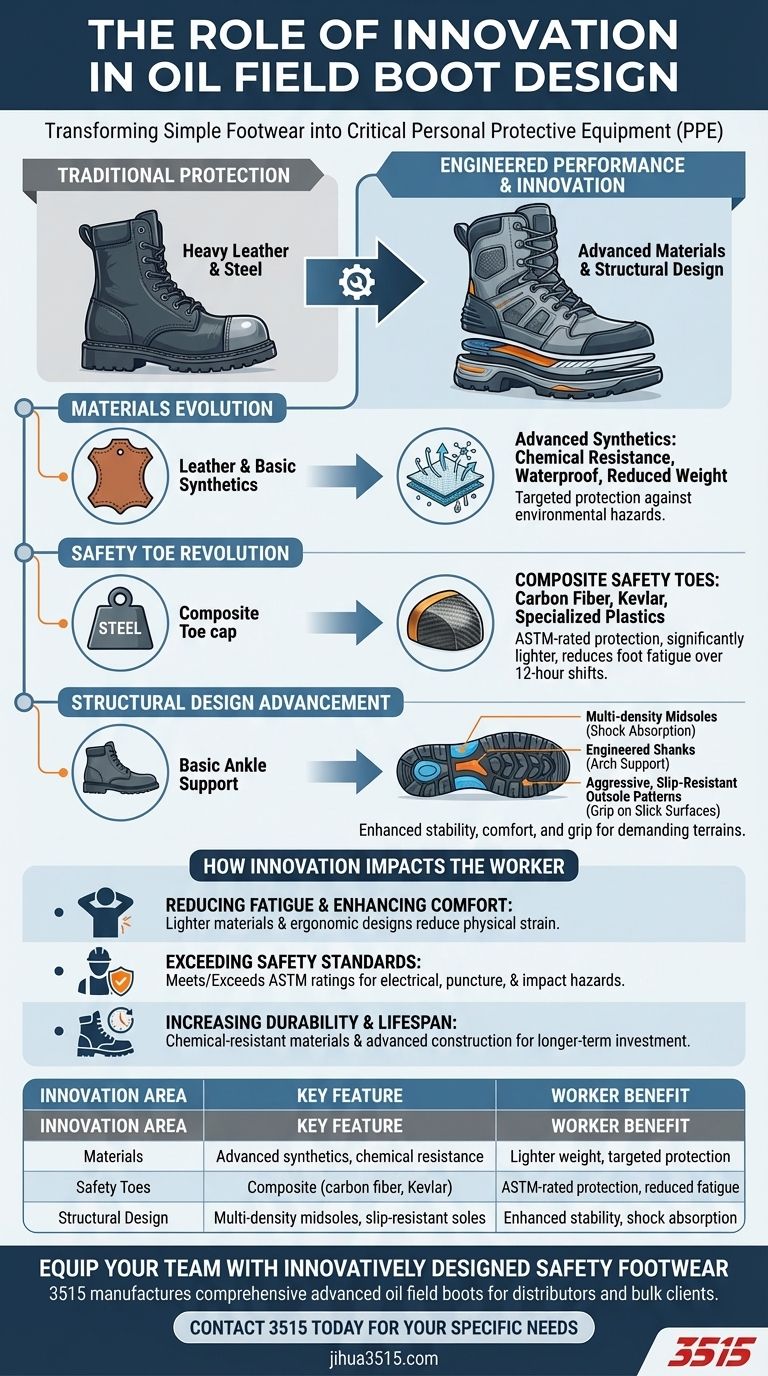

The Shift from Basic Protection to Engineered Performance

Historically, work boots were defined by their toughness, often using heavy leather and steel. Modern innovation has redefined this, focusing on creating highly specialized tools for the feet that offer superior protection without the traditional drawbacks of weight and stiffness.

Beyond Traditional Leather and Steel

The most significant innovations begin with materials. While leather remains a staple, it is now often augmented or replaced by advanced synthetics that offer targeted benefits like superior chemical resistance, waterproofing, and reduced weight. These engineered fabrics provide protection tailored to specific environmental hazards.

The Rise of Composite Safety Toes

The move from steel to composite toe caps is a landmark innovation. Made from materials like carbon fiber, Kevlar, or specialized plastics, these caps offer the same ASTM-rated impact protection as steel but are significantly lighter. This weight reduction directly translates to less foot fatigue over a 12-hour shift, a critical factor for worker endurance and focus.

Advanced Structural Design for Stability

Modern oil field boots feature sophisticated structural designs that go far beyond basic ankle support. Innovations include multi-density midsoles for shock absorption, engineered shanks for arch support on uneven terrain, and aggressive, slip-resistant outsole patterns specifically designed to grip slick, oily surfaces.

How Innovation Directly Impacts the Worker

These technological advancements are not just features on a spec sheet; they have a tangible impact on a worker's daily safety and well-being.

Reducing Fatigue and Enhancing Comfort

By using lighter composite materials and ergonomic designs, innovative boots significantly reduce the physical strain on a worker's feet, legs, and back. This reduction in fatigue is a safety feature in itself, as a tired worker is more prone to accidents.

Exceeding Modern Safety Standards

Innovation is often driven by the need to meet and exceed increasingly stringent industry safety standards. This includes protection against electrical hazards, punctures from below, and impact from above. The R&D departments of leading brands constantly push boundaries to offer a higher level of certified protection.

Increasing Durability and Lifespan

Oil fields are corrosive environments that can rapidly destroy lesser footwear. Innovations in construction methods and the use of chemical-resistant materials mean that a modern boot is not only safer but also represents a better long-term investment by lasting longer under punishing conditions.

Understanding the Trade-offs

While innovation provides clear benefits, it's essential to understand the associated considerations.

Cost vs. Long-Term Value

Advanced materials and extensive research and development come at a price. The most innovative boots are often the most expensive. However, this initial cost must be weighed against their longer lifespan and the invaluable benefit of enhanced safety and comfort.

Material Specialization

There is no single "best" material for every job. An advanced synthetic prized for its chemical resistance may not have the same abrasion resistance as traditional heavy-duty leather. The key is to match the boot's innovative features to the specific hazards of your role.

The Myth of a Single "Do-It-All" Boot

Innovation has led to a high degree of specialization. A boot designed for the extreme cold of a northern operation will have different features than one built for the heat and humidity of an offshore platform. Assuming one innovative design is perfect for all conditions is a common pitfall.

Making the Right Choice for Your Goal

Selecting the right boot means aligning its innovative features with the primary demands of your job.

- If your primary focus is maximum safety against impact and compression: Seek out boots with advanced composite safety toes and integrated metatarsal guards that meet the highest ASTM F2413 safety ratings.

- If your primary focus is all-day comfort and reducing fatigue: Prioritize boots built with lightweight materials, ergonomic ankle support, and advanced, multi-layer cushioning systems in the midsole and footbed.

- If your primary focus is durability against chemicals and harsh terrain: Look for boots constructed with specialized synthetic uppers and direct-attach or Goodyear welt construction for a more robust and water-resistant seal.

Ultimately, choosing a boot with the right innovations is a direct investment in your own safety and professional effectiveness on the job site.

Summary Table:

| Innovation Area | Key Feature | Worker Benefit |

|---|---|---|

| Materials | Advanced synthetics, chemical resistance | Lighter weight, targeted protection |

| Safety Toes | Composite (carbon fiber, Kevlar) | ASTM-rated protection, reduced fatigue |

| Structural Design | Multi-density midsoles, slip-resistant soles | Enhanced stability, shock absorption |

Equip Your Team with Innovatively Designed Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of advanced oil field boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear engineered with the latest innovations in composite materials and ergonomic design to maximize protection and comfort for workers in the most demanding conditions.

Invest in boots that are a direct investment in safety and productivity. Contact 3515 today to discuss your specific needs and discover the right innovative solution for your workforce.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are moc toe boots and why are they popular? The Ultimate Guide to Rugged Style & Comfort

- What additional features do wildland boots have? Unmatched Protection for Extreme Conditions

- What is the necessity of using a Brannock device for sizing protective boots? Master the Art of a Perfect Fit

- What type of sole is required for wildland fire boots? The Critical Safety Standard Explained

- How do work boots protect against common construction hazards? A Guide to Essential Foot Safety

- Why should management prioritize certified high-quality safety boots? Enhance Safety Barriers & Operational Reliability

- Why are industrial safety boots with steel toes necessary for machine operators? Essential Foot Protection for Safety

- What are some ASTM standards for work boots? A Guide to Certified Footwear Safety