In Goodyear Welted shoemaking, skilled professionals are the final arbiters of quality, responsible for transforming a well-constructed shoe into a refined and aesthetically flawless product. Their expertise is most evident in the finishing stages, where they execute the precise decoration, seams, cuts, and broguing that define the shoe's character and ensure its integrity.

The role of a skilled professional is not merely decorative. Their meticulous finishing work is a direct indicator of the shoe's underlying structural integrity and material quality, ensuring the footwear is not only beautiful but built to last for decades.

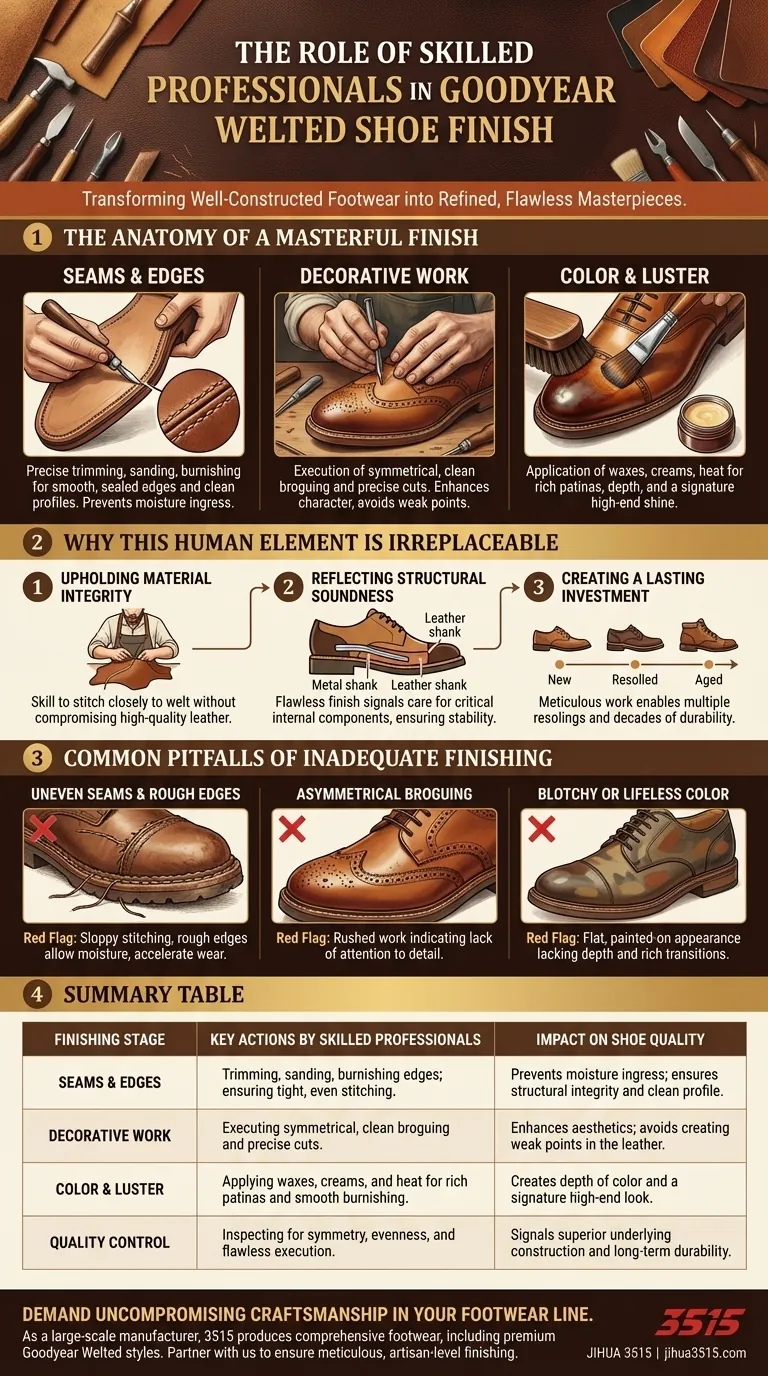

The Anatomy of a Masterful Finish

The term "finish" encompasses a series of critical, hands-on procedures that occur after the main construction of the shoe is complete. This is where the artisan's eye for detail becomes paramount.

Perfecting the Seams and Edges

A defining feature of a Goodyear Welt is the visible seam that joins the upper to the sole. A skilled professional ensures this seam is perfectly executed, with stitching that is both tight and evenly spaced.

They will also meticulously trim, sand, and burnish the edges of the leather sole and heel stack. This creates a smooth, sealed edge that resists moisture and presents a clean, sharp profile.

Executing Precise Decorative Work

Decorative elements like broguing (perforations in the leather) require a steady hand and an expert eye.

Craftsmen ensure these patterns are symmetrical, evenly spaced, and cleanly punched. Poorly executed broguing can not only look sloppy but can also create weak points in the leather upper.

Applying Final Color and Luster

The final stage of finishing involves bringing the leather to life. Artisans use waxes, creams, and heat to burnish the shoe, creating rich patinas and depth of color, especially on the toe and heel.

This highly skilled process is responsible for the signature look of a high-quality dress shoe and cannot be replicated by simple machine polishing.

Why This Human Element Is Irreplaceable

The value of skilled professionals goes far beyond surface aesthetics. Their work is fundamentally linked to the shoe's performance and longevity.

Upholding Material Integrity

Goodyear Welt construction demands high-quality calf hide that can be stitched closely to the edge of the welt.

Only an experienced artisan has the skill to perform this operation without tearing or compromising the integrity of the premium leather, ensuring the upper remains durable for years to come.

Reflecting Structural Soundness

While internal components like the metal and leather shanks provide stability and proper flex, the exterior finish is the ultimate sign of quality control.

A flawless external finish signals that an equal level of care was taken with these critical, unseen structural elements that ensure a balanced and comfortable footprint.

Creating a Lasting Investment

The meticulous work of a finishing professional is a key reason why Goodyear Welted shoes can last for decades.

This attention to detail ensures the shoe is not only beautiful upon purchase but is robust enough to withstand multiple resolings, making it a true long-term investment.

Common Pitfalls of Inadequate Finishing

When craftsmanship is lacking, the shoe's potential is never realized. Recognizing the signs of poor finishing is as important as appreciating good work.

Uneven Seams and Rough Edges

A primary red flag is sloppy stitching along the welt or rough, unfinished sole edges. This not only looks poor but can allow moisture to penetrate the sole, accelerating wear and tear.

Asymmetrical Broguing

Misaligned or inconsistent decorative perforations are a clear sign of rushed or unskilled work. This indicates a lack of attention to detail that likely extends to the shoe's construction.

Blotchy or Lifeless Color

A poor finish will lack the depth and rich, gradual color transitions of a professionally burnished shoe. The color may appear flat, painted on, or blotchy, detracting from the quality of the leather.

How to Assess the Finish for Your Goal

When examining a pair of Goodyear Welted shoes, let the quality of the finish guide your decision.

- If your primary focus is durability: Look for a clean, tightly trimmed welt where the stitching is consistent and sits close to the edge without breaking the leather.

- If your primary focus is aesthetics: Examine the broguing for perfect symmetry and the burnishing on the toe and heel for a smooth, gradual transition of color.

- If your primary focus is overall quality: Check the evenness of the sole edge finishing and ensure all cuts are clean and free of any nicks or rough patches.

Ultimately, the hands of a skilled professional are what elevate a Goodyear Welted shoe from a mere product to a piece of lasting craftsmanship.

Summary Table:

| Finishing Stage | Key Actions by Skilled Professionals | Impact on Shoe Quality |

|---|---|---|

| Seams & Edges | Trimming, sanding, burnishing sole edges; ensuring tight, even stitching. | Prevents moisture ingress; ensures structural integrity and a clean profile. |

| Decorative Work | Executing symmetrical, clean broguing and precise cuts. | Enhances aesthetics; avoids creating weak points in the leather. |

| Color & Luster | Applying waxes, creams, and heat for rich patinas and smooth burnishing. | Creates depth of color and a signature high-end look. |

| Quality Control | Inspecting for symmetry, evenness, and flawless execution. | Signals superior underlying construction and long-term durability. |

Demand Uncompromising Craftsmanship in Your Footwear Line

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including premium Goodyear Welted styles. We understand that the final finish is what transforms a well-constructed shoe into a masterpiece that commands attention and lasts for decades.

Partner with us to ensure your products feature the meticulous, skilled finishing detailed in this article. We combine advanced manufacturing with artisan-level attention to detail, delivering footwear that excels in both durability and aesthetics.

Contact our team today to discuss how we can bring this level of quality and craftsmanship to your next order.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- How should dress shoes be maintained to prolong their lifespan? A Guide to Lasting Quality

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look

- What types of dress shoes are recommended for formal occasions? A Guide to Impeccable Style

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear