In short, safety shoes are essential personal protective equipment (PPE) designed to mitigate a wide range of common and severe risks in manufacturing. They provide a critical barrier against mechanical impacts from falling objects, punctures from sharp materials, electrical shocks, chemical spills, extreme temperatures, and dangerous slips on compromised surfaces.

The core function of safety footwear extends far beyond the well-known steel toe. It is a highly engineered system designed to counteract the specific, multi-faceted hazards of a given manufacturing environment, from the factory floor to the chemical storage room.

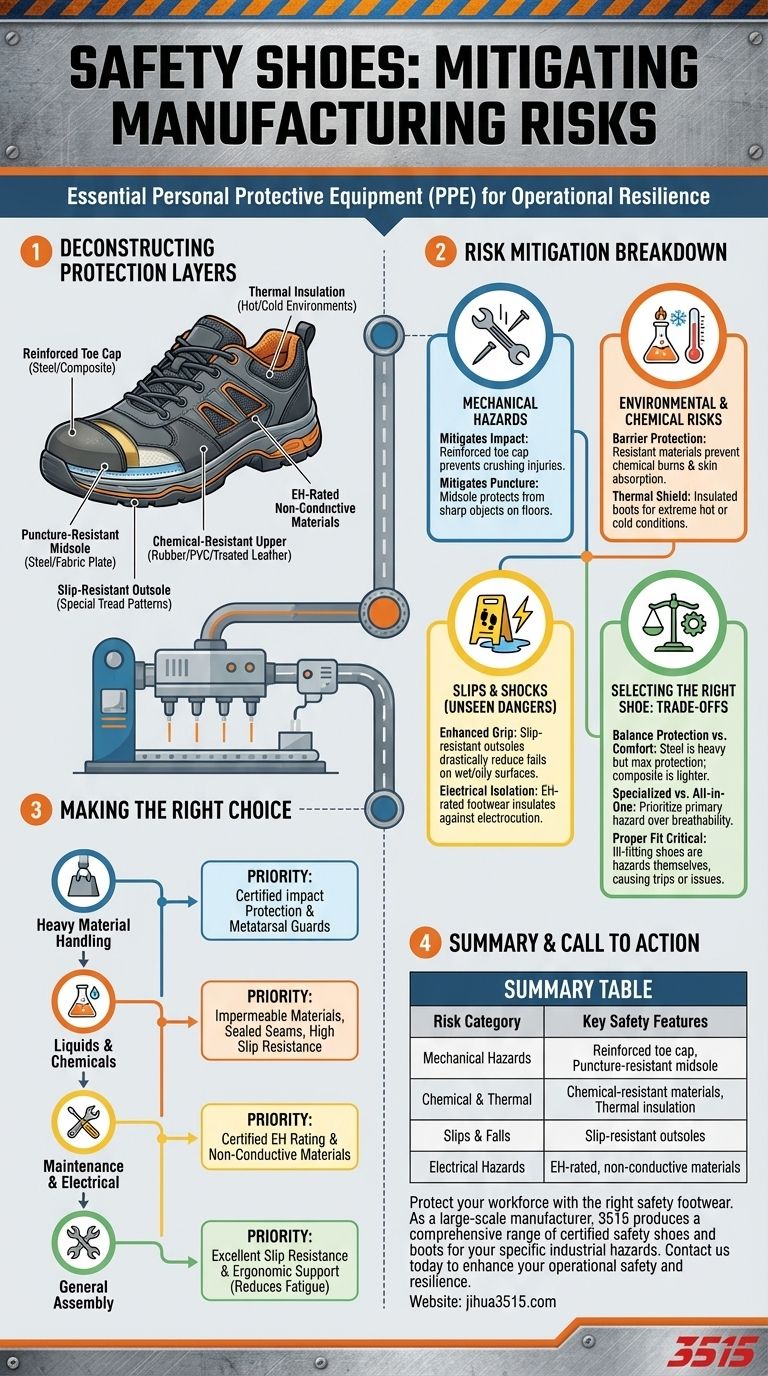

Deconstructing the Layers of Protection

Understanding how safety shoes work requires looking at each type of risk they are designed to prevent. The right shoe is not a one-size-fits-all solution but a specific tool for a specific job.

Mechanical Hazards: The Most Common Threat

The most intuitive function of safety shoes is to protect against direct physical force.

This protection is primarily delivered through a reinforced toe cap, typically made of steel or lighter composite materials, which prevents crushing injuries from dropped tools or materials.

A second layer of mechanical defense is the puncture-resistant midsole. This feature, often a steel or fabric plate, protects the sole of the foot from nails, scrap metal, and other sharp objects on the floor.

Environmental and Chemical Risks

Manufacturing floors are often unpredictable environments where spills are a constant risk.

Safety footwear made from materials like rubber, PVC, or specially treated leather provides a barrier against acids, solvents, and other hazardous chemicals, preventing burns and skin absorption.

For environments with extreme temperatures, such as foundries or cold storage, thermally insulated boots protect against burns or frostbite, ensuring worker safety and comfort.

The Unseen Dangers: Slips and Shocks

Some of the most frequent manufacturing injuries come from less obvious sources.

Slip-resistant outsoles are one of the most critical safety features. They are designed with specific tread patterns and compounds to maintain grip on wet, oily, or uneven surfaces, drastically reducing falls.

For those working near live circuits, Electrical Hazard (EH) rated footwear is essential. These shoes are built with non-conductive materials to insulate the wearer from the ground, mitigating the risk of electrocution.

Understanding the Trade-offs

Selecting the right safety shoe involves balancing protection with practicality. A failure to consider the trade-offs can lead to non-compliance or even new safety issues.

Protection vs. Weight and Comfort

Heavier materials like steel offer maximum impact protection but can increase fatigue over a long shift. Lighter composite materials provide excellent protection for many applications and reduce worker strain.

Specialized vs. All-in-One Designs

A boot designed for maximum chemical resistance may not offer the best breathability or flexibility. It's crucial to identify the primary hazard in your specific work area rather than seeking a single shoe that claims to do everything.

The Critical Importance of a Proper Fit

An ill-fitting safety shoe is a hazard in itself. Footwear that is too loose can cause tripping, while shoes that are too tight can create blisters and long-term foot problems, leading to distraction and potential accidents.

Making the Right Choice for Your Environment

Your specific operational role dictates the type of protection you need.

- If your primary focus is heavy material handling: Prioritize footwear with certified impact protection (steel or composite toe) and consider additional metatarsal guards.

- If your primary focus is working around liquids or chemicals: Select boots made from impermeable materials with sealed seams and a high degree of slip resistance.

- If your primary focus is maintenance or electrical work: Ensure your footwear has a certified Electrical Hazard (EH) rating and is made from non-conductive materials.

- If your primary focus is general assembly on hard floors: Look for excellent slip resistance and strong ergonomic support to reduce fatigue and prevent musculoskeletal strain.

Choosing the right safety shoe is a foundational investment in personal safety and operational resilience.

Summary Table:

| Risk Category | Key Safety Features |

|---|---|

| Mechanical Hazards | Reinforced toe cap (steel/composite), Puncture-resistant midsole |

| Chemical & Thermal | Chemical-resistant materials (rubber, PVC), Thermal insulation |

| Slips & Falls | Slip-resistant outsoles |

| Electrical Hazards | EH-rated, non-conductive materials |

Protect your workforce with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear tailored to your specific industrial hazards. Contact us today to enhance your operational safety and resilience.

Visual Guide

Related Products

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- Why must insulating safety shoes be placed in a temperature-controlled environment? Ensure True Safety Test Results

- How do industrial safety boots assist maintenance personnel working on high-level palm oil factory structures?

- What are the main stages involved in safety shoes manufacturing? A Guide to Durable, Protective Footwear

- What materials are typically used in safety trainers? A Guide to Protective Footwear Components

- What are the OSHA requirements for security guard safety boots? Choose the Right Protection for Your Team

- How do Weather-resistant safety boots perform in different conditions? Find the Right Boot for Your Job

- What role do integrated pressure-sensing insoles play in safety shoes for assessing lower back disease risk?

- Why are professional conveyor systems used for process flow management in safety shoe production? Ensure Consistency