In essence, a non-slip shoe is defined by a specific combination of material and design in its outsole. It must have a high-quality, soft rubber-like sole engineered with a distinct tread pattern of deep grooves. This system is designed to maintain grip on wet or oily surfaces by channeling liquids away from the point of contact.

The defining characteristic of a non-slip shoe isn't just the material it's made from, but the functional design of its tread. The ultimate goal is to maximize the friction between the shoe and the floor by effectively clearing away any liquid contaminants.

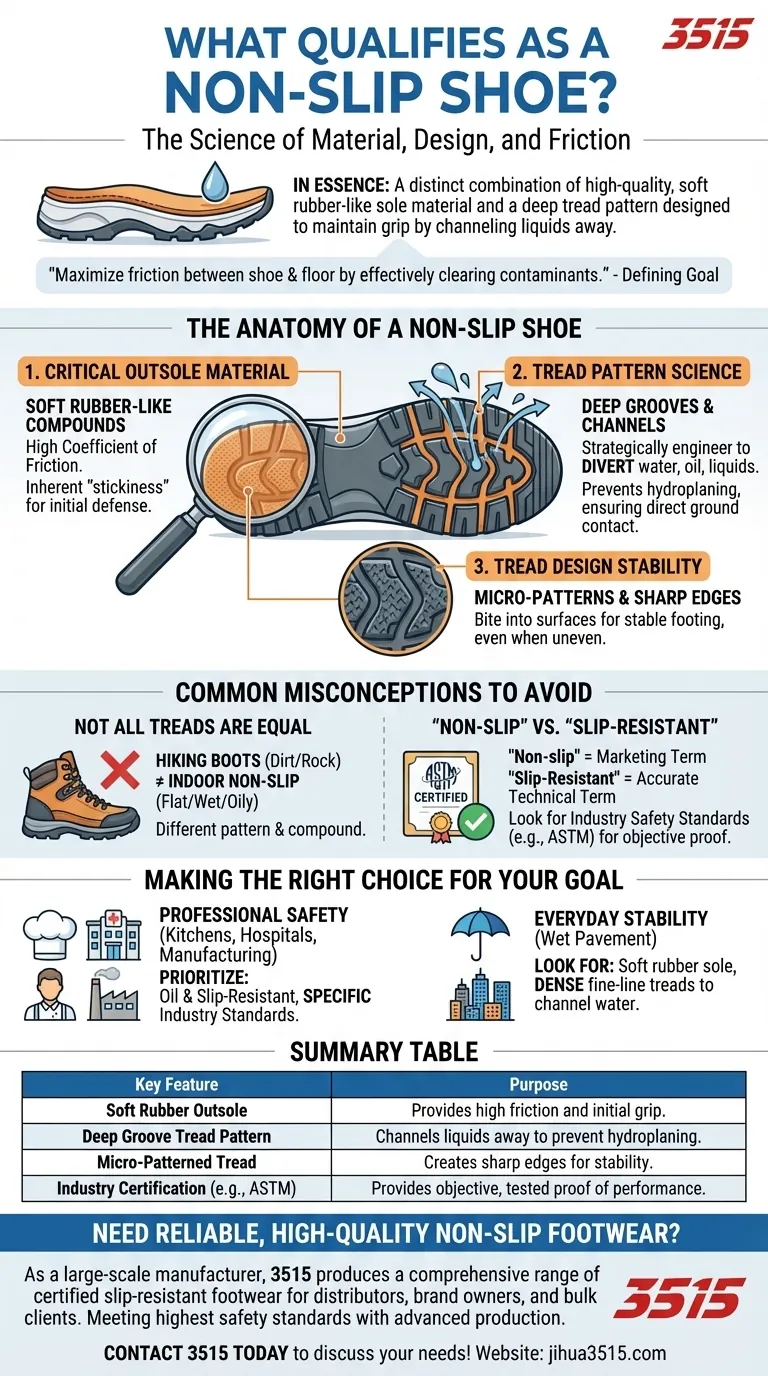

The Anatomy of a Non-Slip Shoe

To truly qualify as non-slip, a shoe must integrate several key design elements that work together. Each component serves a specific purpose in preventing accidents.

The Critical Role of the Outsole Material

The foundation of a slip-resistant shoe is the outsole material. Manufacturers typically use soft, rubber-like compounds.

These materials are chosen for their high coefficient of friction, which is the scientific measure of how much grip a surface has. This inherent "stickiness" provides the initial layer of defense against a slip.

The Science of Tread Patterns

The pattern on the bottom of the shoe is its most important functional feature. These aren't random designs for aesthetics.

Deep grooves and channels are strategically engineered to divert water, oil, and other liquids out from under the shoe's sole. This action prevents a dangerous phenomenon similar to a car hydroplaning, allowing the outsole to make direct contact with the solid ground.

How Tread Design Ensures Stability

Beyond just channeling liquid, the tread pattern consists of many small, intricate shapes.

These micro-patterns are designed to create numerous sharp edges that can bite into the walking surface, providing stable footing even when the surface is not perfectly even or clean.

Common Misconceptions to Avoid

Understanding what a non-slip shoe is also means understanding what it is not. Marketing claims can be confusing, so it's crucial to focus on the functional realities.

Not All Treads Are Created Equal

Simply having a deep tread, like on a hiking boot, does not automatically make a shoe slip-resistant for indoor surfaces.

Hiking treads are designed for dirt and rock, whereas non-slip treads are specifically designed for flat, wet, and oily surfaces. The pattern and rubber compound are fundamentally different.

The "Slip-Resistant" Designation Matters

While often used interchangeably, "non-slip" is more of a marketing term. "Slip-resistant" is the more accurate technical term.

Look for shoes that are explicitly tested and certified to meet industry safety standards (like those from ASTM). This provides an objective measure of the shoe's performance. No shoe can guarantee that a slip will never happen, but a certified shoe is proven to significantly reduce that risk.

Making the Right Choice for Your Goal

Selecting the correct shoe depends entirely on the environment where it will be used.

- If your primary focus is professional safety (kitchens, hospitals, manufacturing): Prioritize shoes that explicitly state they are oil and slip-resistant and meet specific industry safety standards.

- If your primary focus is everyday stability on wet pavement: Look for shoes with a soft rubber sole and a dense pattern of fine-line treads designed to channel water effectively.

Ultimately, identifying a true non-slip shoe requires looking past marketing and examining the science of its sole.

Summary Table:

| Key Feature | Purpose |

|---|---|

| Soft Rubber Outsole | Provides high friction and initial grip on slippery surfaces. |

| Deep Groove Tread Pattern | Channels water, oil, and liquids away from the sole to prevent hydroplaning. |

| Micro-Patterned Tread | Creates sharp edges for stability and to bite into uneven or contaminated surfaces. |

| Industry Certification (e.g., ASTM) | Provides objective, tested proof of slip-resistant performance. |

Need Reliable, High-Quality Non-Slip Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified slip-resistant footwear for distributors, brand owners, and bulk clients. We ensure every pair meets the highest safety standards with our advanced production capabilities for all types of shoes and boots.

Contact 3515 today to discuss your safety footwear needs and get a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- Why is slip resistance important in safety footwear? Prevent Costly Workplace Slips and Falls

- What are the EN ISO 20345 norms for safety shoes? A Guide to Choosing the Right Protection

- What should warehouse work shoes include for safety? Essential Features for All-Day Protection

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles