Numerous professions require safety shoes, but the requirement is defined by the specific hazards of the job, not just the job title. Key sectors where they are essential include construction, manufacturing, logistics, and warehousing, as well as specialized roles in healthcare, laboratories, and utilities where risks of impact, puncture, or chemical spills are present.

The need for safety footwear is determined not by a profession's name, but by a formal assessment of the potential workplace hazards to an employee's feet. Understanding the specific risks—from falling objects to electrical currents—is the only way to ensure proper protection.

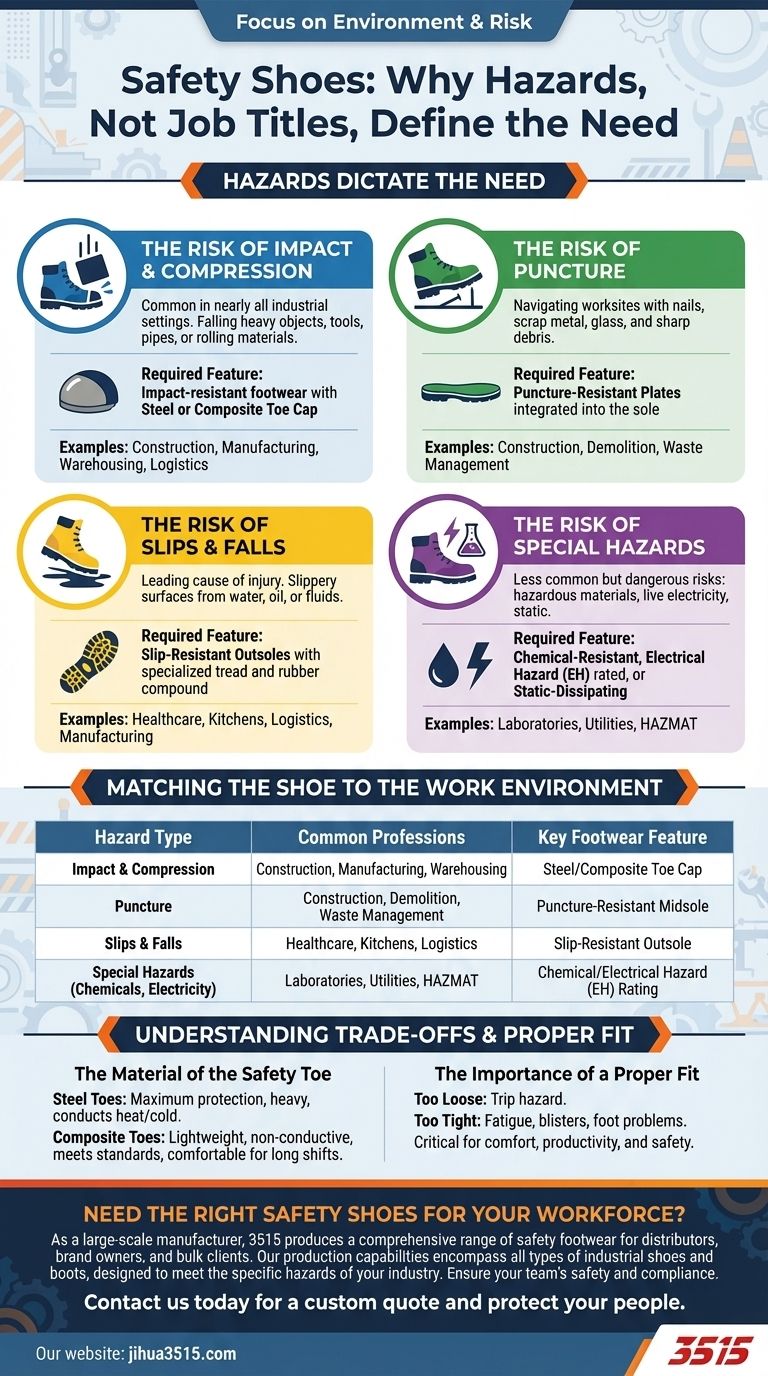

Why Hazards Dictate the Need, Not Job Titles

Thinking about safety shoes should begin with the environment, not the role. A warehouse manager who spends all day at a desk has different needs than a worker on the floor. The core principle is to match the protection to the risk.

The Risk of Impact and Compression

The most common hazard is something heavy falling or rolling onto the foot. This is a primary concern in nearly all industrial settings.

Handling heavy objects, tools, pipes, or raw materials that could be dropped necessitates impact-resistant footwear, typically with a steel or composite toe cap. Similarly, working around rolling items like wheels, drums, or carts requires protection against compression.

The Risk of Puncture

Walking on a worksite often means navigating nails, scrap metal, glass, and other sharp debris. This is especially prevalent in construction, demolition, and waste management.

Footwear with puncture-resistant plates integrated into the sole is critical in these environments to prevent sharp objects from piercing the bottom of the shoe.

The Risk of Slips and Falls

According to the National Safety Council, falls are a leading cause of workplace injury. Slippery surfaces from water, oil, or other fluids are common in manufacturing, kitchens, healthcare, and logistics.

Slip-resistant outsoles are a non-negotiable feature in these settings. The tread pattern and rubber compound are specifically engineered to provide a secure grip on hazardous floors.

The Risk of Special Hazards

Some jobs involve less common but equally dangerous risks that require specialized footwear.

This includes exposure to hazardous materials (HAZMAT), which demands chemical-resistant boots, or working with live electrical components, which requires boots with an Electrical Hazard (EH) rating. Conversely, environments with sensitive electronics may require static-dissipating shoes to prevent damage.

Matching the Shoe to the Work Environment

Different industries consolidate these risks in unique ways, leading to specific footwear recommendations.

For Construction and Heavy Industry

Workers in these fields face a combination of impact, compression, and puncture risks daily.

Their boots must have protective toe caps and puncture-resistant soles. Metatarsal guards, which protect the top of the foot, are also common for extreme-duty work.

For Manufacturing and Logistics

These environments are defined by concrete floors, heavy machinery, and pallet jacks. The primary risks are falling objects and slippery surfaces.

The standard footwear combines a safety toe for impact protection with a high-traction, slip-resistant outsole to ensure stability.

For Laboratories and Healthcare

While not heavy industry, these settings have unique risks like dropped sharps (needles, scalpels) and chemical spills.

Footwear here prioritizes fluid resistance, easy cleanability, and slip resistance. Many professionals opt for composite toes, which are lighter than steel and do not conduct electricity.

Understanding the Trade-offs

Choosing the right shoe is not just about meeting a safety checklist; it's also about ensuring the footwear is practical for daily wear. An uncomfortable or ill-fitting shoe can create its own safety hazards.

The Material of the Safety Toe

Steel toes are the traditional standard, offering maximum protection. However, they are heavy and conduct heat and cold.

Composite toes (made of materials like Kevlar, carbon fiber, or plastic) are much lighter and do not conduct temperature, making them more comfortable for long shifts. They provide ample protection that meets regulatory standards for most jobs.

The Importance of a Proper Fit

A safety shoe that is too loose can be a trip hazard, while one that is too tight can cause fatigue, blisters, and long-term foot problems.

Ensuring a proper fit is as critical as the safety features themselves. It directly impacts a worker's comfort, productivity, and overall safety throughout the day.

Beyond the Basic Requirements

Simply having a safety toe is not enough. The overall quality of the shoe—from the outsole material to the upper construction—determines its durability and effectiveness. Investing in well-made footwear from a reputable brand is an investment in personal well-being.

How to Select the Right Foot Protection

Your choice should be guided by a clear understanding of your daily tasks and environment.

- If your primary focus is protection from heavy impact: Look for safety shoes with steel or composite toes that meet the required impact and compression safety standards for your region.

- If your primary focus is working around sharp objects: Prioritize footwear with built-in, puncture-resistant midsoles to protect against nails and other debris.

- If your primary focus is preventing slips and falls: Seek out shoes with a certified slip-resistant outsole designed for the specific surfaces you encounter, such as oily or wet floors.

- If your primary focus is handling chemicals or electricity: Ensure your footwear carries the specific ratings for chemical resistance or Electrical Hazard (EH) protection.

Ultimately, the right safety shoe is a critical tool that empowers you to perform your job confidently and without injury.

Summary Table:

| Hazard Type | Common Professions | Key Footwear Feature |

|---|---|---|

| Impact & Compression | Construction, Manufacturing, Warehousing | Steel/Composite Toe Cap |

| Puncture | Construction, Demolition, Waste Management | Puncture-Resistant Midsole |

| Slips & Falls | Healthcare, Kitchens, Logistics | Slip-Resistant Outsole |

| Special Hazards (Chemicals, Electricity) | Laboratories, Utilities, HAZMAT | Chemical/Electrical Hazard (EH) Rating |

Need the right safety shoes for your workforce? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial shoes and boots, designed to meet the specific hazards of your industry—from impact-resistant steel toes to chemical-proof boots. Ensure your team's safety and compliance with durable, comfortable footwear built for long shifts. Contact us today for a custom quote and discover how we can protect your most valuable asset: your people.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the different types of safety toes? Choose the Right Protection for Your Job

- In what way does professional footwear complement respiratory protection in pest control? Total Barrier Health Safety

- What are the performance advantages of using EVA as an outsole material? Enhancing Safety Shoe Grip and Comfort

- What is the mechanism of impact resistance testing in safety footwear? Ensure Top-Tier Toe Protection Standards

- What are the advantages of using an active buzzer and vibration motor in smart shoes? Enhance Safety with Dual Alerts

- What safety benefits do safety shoes with electrical insulation provide? Expert Protection for Sewing Operations

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- What role does PPE like safety shoes play in manual concrete handling? Key Benefits for Operator Stability