In short, OSHA requires employers to provide protective footwear to any employee working in an area where there is a danger of foot injury. These dangers are broadly defined as falling or rolling objects, objects that could pierce the sole of the shoe, and exposure to electrical hazards. The specific type of footwear required must be chosen based on the specific hazards present in the work environment.

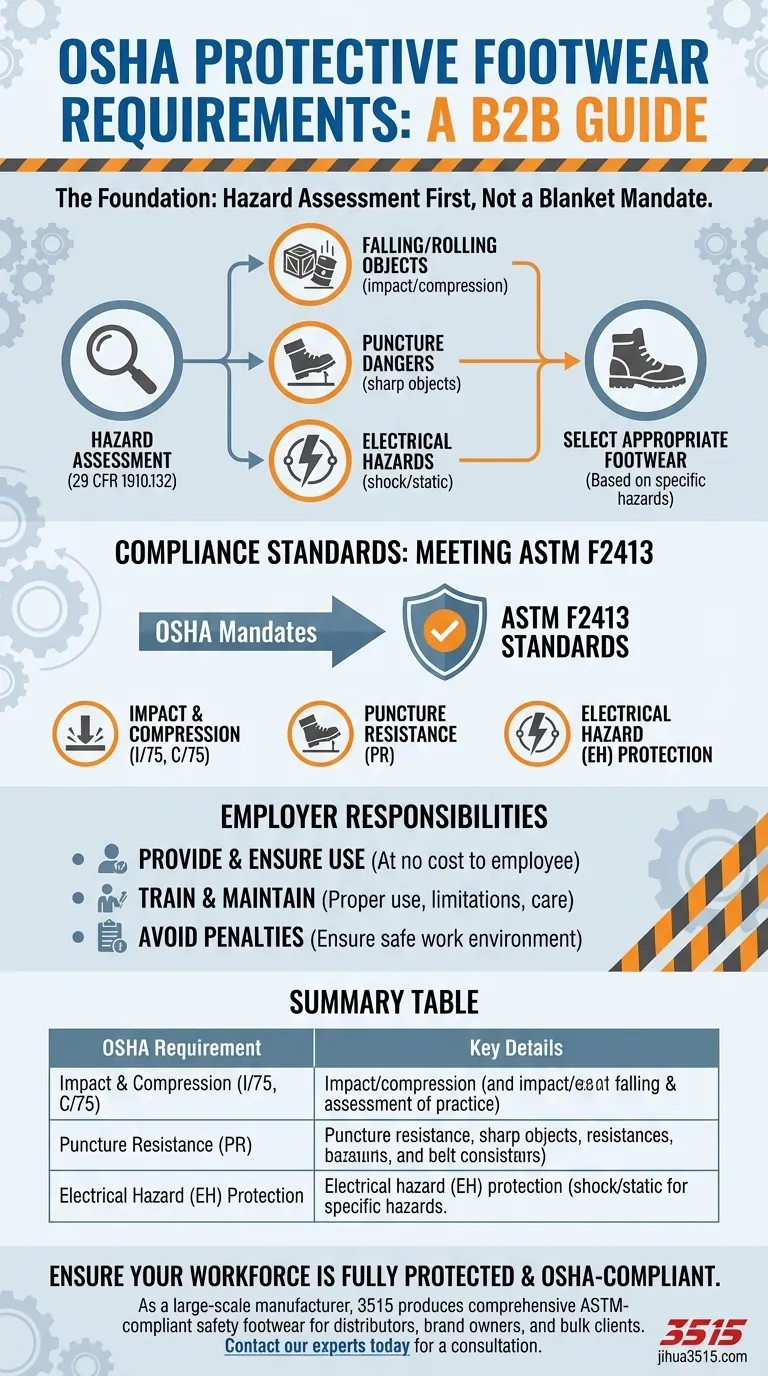

The core principle of OSHA's footwear requirement is not a blanket mandate for "steel-toed boots," but a requirement for employers to first conduct a thorough hazard assessment. The specific dangers of the job site dictate the specific type of protective footwear that must be used.

When is Protective Footwear Mandatory?

The obligation to use protective footwear is triggered by the presence of specific, identifiable risks in the workplace. The employer is responsible for recognizing these risks and mandating the appropriate protection.

The Hazard Assessment Imperative

According to OSHA standard 29 CFR 1910.132, the entire process begins with a workplace hazard assessment. The employer must survey the work environment to identify any potential dangers to employees' feet. This assessment is the foundation for all subsequent decisions about personal protective equipment (PPE).

Falling or Rolling Objects

This is the most common and widely understood foot hazard. It applies to environments like construction sites, warehouses, loading docks, and manufacturing floors where heavy materials are moved or stored. The risk is from compression or impact injuries caused by these objects.

Puncture Dangers

Workplaces such as demolition sites, scrap yards, or construction zones often have sharp objects on the ground. Nails, screws, rebar, and sharp metal scraps can easily pierce the sole of a standard shoe, causing serious injury.

Electrical Hazards

OSHA’s standard 29 CFR 1910.136 explicitly calls out electrical hazards. This category includes risks of electric shock from contact with live circuits or static discharge that could ignite flammable materials. Footwear designed for these risks is fundamentally different from standard impact-resistant boots.

What Kind of Footwear Meets OSHA Standards?

OSHA does not design or manufacture safety footwear. Instead, it mandates that the equipment used must meet established, independent industry standards to be considered compliant.

The Role of Consensus Standards (ASTM)

For a safety shoe to be compliant, it must meet the criteria set by organizations like the American Society for Testing and Materials (ASTM). The relevant standard, ASTM F2413, specifies the performance requirements for footwear in areas like impact resistance, compression resistance, and electrical hazard protection.

Matching the Boot to the Hazard

A boot that is compliant for impact resistance may offer no protection against electrical shock. An employer must select footwear that is explicitly rated for the specific hazards identified in their assessment. The label inside the footwear will indicate which ASTM standards it meets.

Understanding Employer Responsibilities

OSHA places the legal responsibility for compliance squarely on the employer. This responsibility extends beyond simply making a purchase.

The Duty to Provide and Ensure Use

The employer must not only select and provide the appropriate protective footwear at no cost to the employee, but they must also ensure it is used correctly and consistently. A policy that is not enforced does not meet OSHA requirements.

Training and Maintenance

Employers are also responsible for training employees on when the PPE is necessary, how to wear it properly, and what its limitations are. They must also ensure the footwear is maintained in a clean and reliable condition.

Consequences of Non-Compliance

Failure to assess hazards and provide the necessary protective footwear can result in significant OSHA penalties. More importantly, it creates an unsafe work environment and exposes employees to preventable, and often severe, injuries.

Making the Right Choice for Your Work Environment

Your hazard assessment is the only true guide, but certain job types have predictable footwear needs.

- If your primary focus is warehousing or manufacturing: Your key concern is impact and compression from falling objects, so footwear rated for I/75 and C/75 under ASTM standards is the baseline.

- If your primary focus is construction or demolition: You need impact and compression protection plus puncture resistance (PR) to protect against nails and other sharp debris.

- If your primary focus is electrical work: You must provide footwear specifically rated for Electrical Hazard (EH) protection, which is designed to insulate the wearer from the ground.

Ultimately, protecting your team starts with a clear-eyed assessment of the real-world dangers they face every day.

Summary Table:

| OSHA Requirement | Key Details |

|---|---|

| Hazard Assessment | Mandatory per 29 CFR 1910.132 to identify risks like impact, puncture, or electrical hazards. |

| Footwear Standard | Must meet ASTM F2413 for specific protections (e.g., I/75, C/75, PR, EH). |

| Employer Duty | Provide, ensure use, and train employees on correct PPE at no cost to them. |

Ensure your workforce is fully protected and OSHA-compliant.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, from impact-resistant models for warehouses to puncture-proof and electrical hazard-rated boots for high-risk environments.

We can help you source the right protective footwear to meet your specific hazard assessment needs, ensuring worker safety and regulatory compliance. Contact our experts today for a consultation and to discuss your requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture