The most comfortable construction boots are not defined by a single material, but by a strategic system of materials working together. True comfort comes from a combination of flexible and supportive uppers like high-quality leather, shock-absorbing midsoles, and advanced linings like Gore-Tex that manage moisture and temperature.

True boot comfort is an engineering outcome, not a feature of one material. It's achieved when the upper, lining, and sole system work in concert to manage impact, moisture, and support throughout the workday.

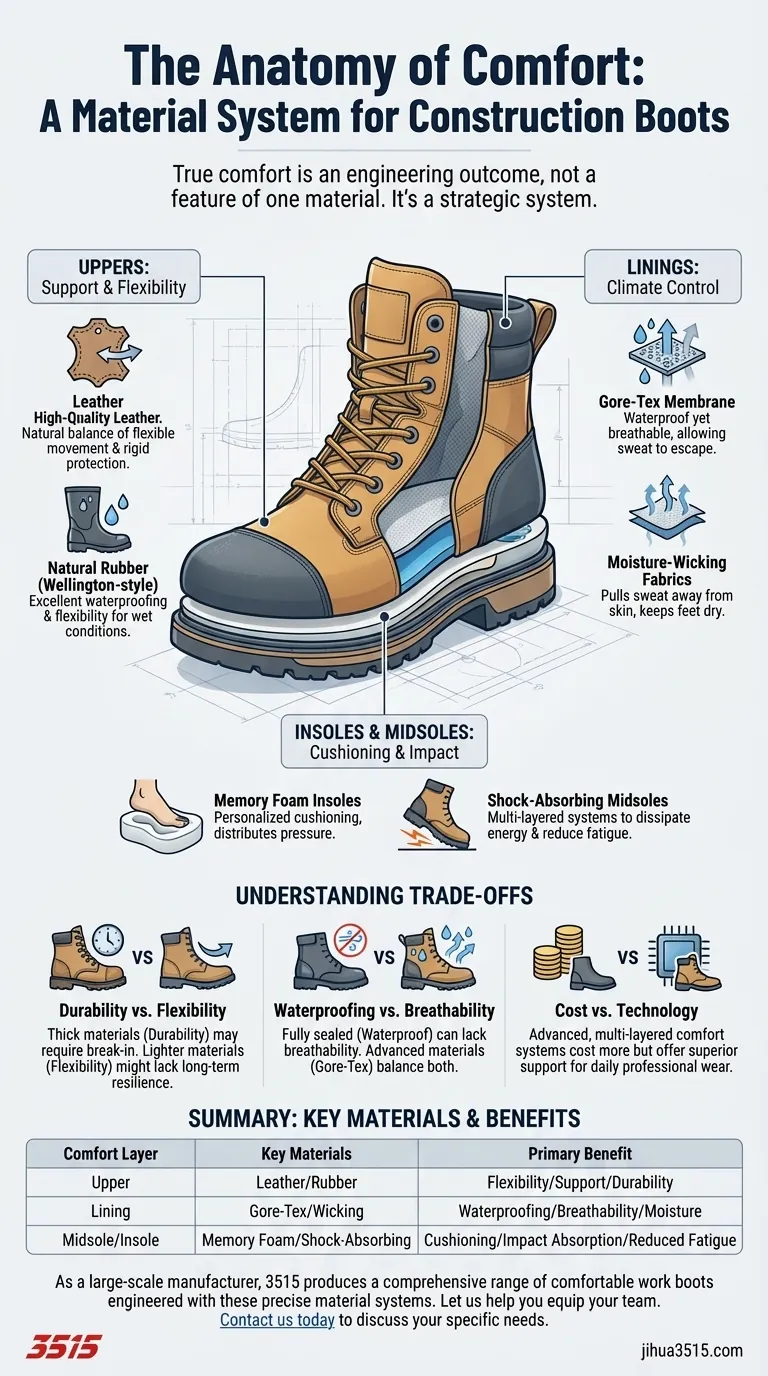

The Anatomy of a Comfortable Boot: A Material System

A boot isn't a single piece; it's a layered structure. Each layer uses specific materials chosen for a distinct function. Understanding these layers is the key to identifying a truly comfortable boot.

Uppers: The First Line of Defense and Support

The upper is the main body of the boot. Its material dictates the boot's flexibility, durability, and overall support structure.

Leather is the traditional and often superior choice for boot uppers. Its natural fibers provide an ideal balance of flexibility for movement and rigid support to protect your foot. It also offers a degree of natural breathability.

Natural rubber is another key material, primarily used in Wellington-style boots. It provides excellent waterproofing and flexibility, making it highly comfortable for work in consistently wet or muddy conditions.

Linings: Managing Moisture and Temperature

The material inside the boot is critical for managing the interior climate, which directly impacts comfort and foot health.

Gore-Tex is a well-known example of a high-performance lining. This synthetic membrane contains microscopic pores that are too small for water droplets to enter but large enough for water vapor (sweat) to escape, providing both waterproofing and breathability.

Moisture-wicking fabrics are designed to pull sweat away from the skin and move it to the outer surface of the fabric, where it can evaporate. This keeps feet dry and prevents the discomfort and blisters associated with damp socks.

Insoles and Midsoles: The Core of Cushioning

This is the part of the boot that absorbs shock and provides direct underfoot comfort. It is arguably the most critical component for preventing fatigue.

Memory foam is often used in insoles to provide personalized cushioning. It contours to the unique shape of your foot, distributing pressure evenly and reducing stress on key impact points.

Shock-absorbing midsoles are engineered to dissipate the energy from each step you take on hard surfaces. These multi-layered systems reduce the fatigue that travels up your legs and back over a long day.

Understanding the Trade-offs

No single material solves every problem. Choosing the right boot means understanding the inherent compromises between different materials and features.

Durability vs. Flexibility

Highly durable materials like thick leather provide excellent protection and longevity but may require a break-in period to become fully flexible. Lighter materials may offer instant comfort but lack the same long-term resilience.

Waterproofing vs. Breathability

The ultimate challenge is keeping water out while letting sweat escape. A fully sealed material like PVC is completely waterproof but offers zero breathability, which can lead to discomfort. Advanced materials like Gore-Tex solve this but come at a significantly higher cost.

Cost vs. Advanced Technology

Boots featuring multi-layered comfort systems, advanced linings, and specialized materials will invariably cost more. While a more affordable boot made of a single material like PVC might suffice for occasional use, it will not provide the same level of comfort and support for daily professional wear.

Making the Right Choice for Your Work Environment

Your specific needs should guide your material choice. Consider the primary demands of your job to select a boot that is engineered for your environment.

- If your primary focus is all-day wear on varied terrain: Prioritize a boot with a high-quality leather upper and a multi-layered comfort system featuring a shock-absorbing midsole.

- If your primary focus is working in wet or unpredictable weather: Look for a boot with a waterproof and breathable lining like Gore-Tex to keep your feet dry from both external and internal moisture.

- If your primary focus is comfort and flexibility in damp conditions: A Wellington boot made from natural rubber offers an excellent combination of waterproofness and comfort without restricting movement.

Ultimately, the right choice is a system of materials engineered to meet the specific demands of your workday.

Summary Table:

| Comfort Layer | Key Materials | Primary Benefit |

|---|---|---|

| Upper | High-Quality Leather, Natural Rubber | Flexibility, Support, Durability |

| Lining | Gore-Tex, Moisture-Wicking Fabrics | Waterproofing, Breathability, Moisture Management |

| Midsole/Insole | Memory Foam, Shock-Absorbing Systems | Cushioning, Impact Absorption, Reduced Fatigue |

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of comfortable work boots and shoes, engineered with the precise material systems detailed above to ensure superior comfort, durability, and performance for your workforce. Let us help you equip your team with the best. Contact us today to discuss your specific needs and receive a customized solution!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- Why is proper fit crucial for firefighters' footwear? Avoid Injury and Boost Performance

- How is all-around comfort achieved in western boots? Discover the Integrated Comfort System

- How do wildland firefighting boots differ from traditional bunker boots? A Guide to Choosing the Right Footwear for Your Mission

- Why do fire boots have a heel? The Critical Safety Feature for Firefighters

- What safety considerations should be made when choosing Wellington work boots? Match Boot Features to Your Job's Hazards

- What features should heavy machinery workers look for in work boots? Essential Safety and Durability Guide

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health

- What types of workers commonly use Wellington boots? Essential Footwear for Demanding Professions