To construct oil-resistant safety boots, manufacturers primarily utilize specialized polymers for the outsole and durable, protective fabrics for the upper. The most effective soles are engineered from rubber or Thermoplastic Polyurethane (TPU) to prevent chemical degradation, while uppers typically feature leather, rubber, or reinforced nylon to balance durability with breathability.

Core Insight: While many boots claim general durability, true oil resistance depends entirely on the chemical stability of the outsole material. Choosing the wrong polymer—even in a sturdy-looking boot—can lead to rapid material disintegration and a dangerous loss of traction when exposed to industrial lubricants or fuels.

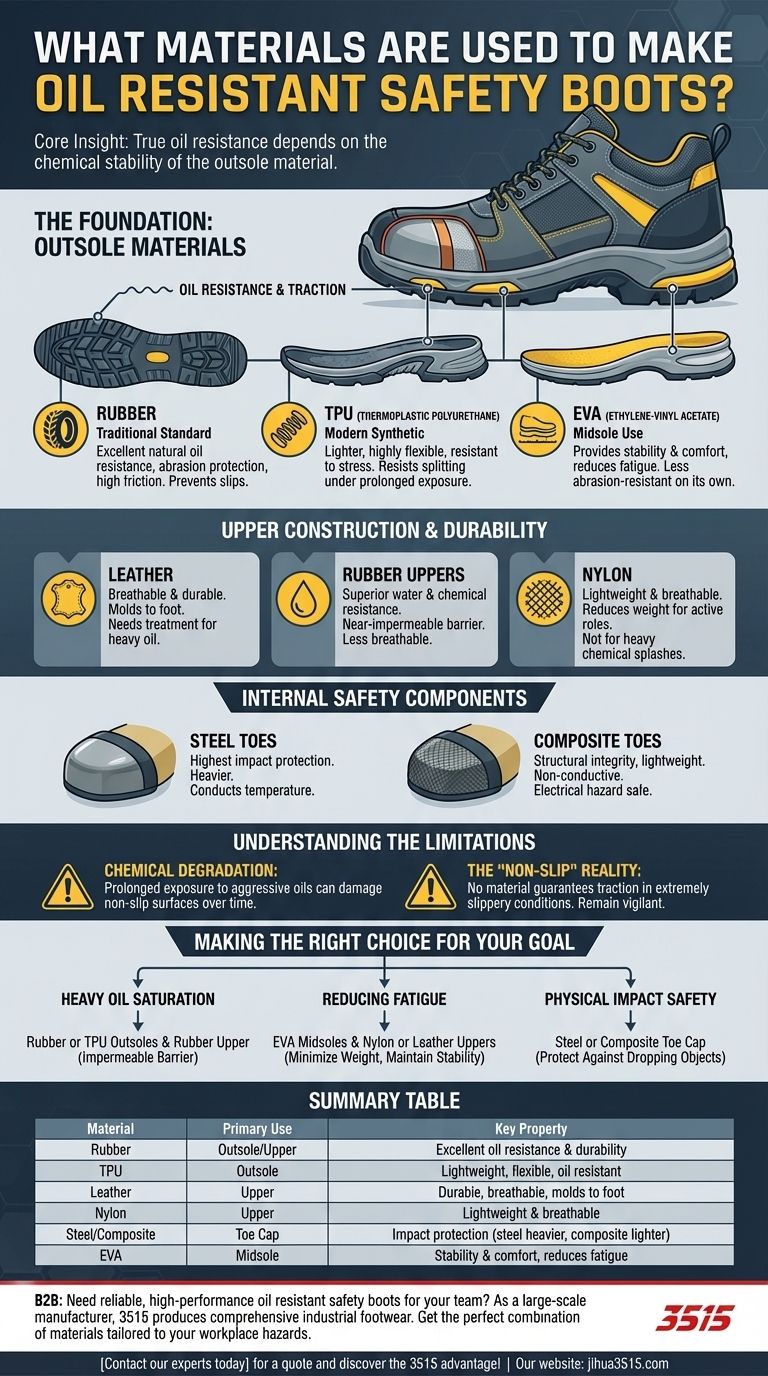

The Foundation: Outsole Materials

The outsole is your primary defense against oily surfaces. This component determines the boot's traction and its ability to resist swelling or dissolving when in contact with hydrocarbons.

Rubber

Rubber is the traditional standard for industrial footwear. It offers excellent natural resistance to oils and significant protection against abrasion.

It provides a high coefficient of friction, helping to prevent slips in environments like oil fields or heavy machinery floors.

Thermoplastic Polyurethane (TPU)

TPU is a modern, synthetic alternative that is often lighter than traditional rubber.

It is highly flexible and resistant to stress, making it an excellent durable option that resists splitting even after prolonged exposure to oils and chemicals.

Ethylene-Vinyl Acetate (EVA)

EVA is frequently used in conjunction with harder outsole materials, often serving as the midsole.

It provides stability and comfort, reducing fatigue for workers standing all day, though it is generally less abrasion-resistant on its own compared to Rubber or TPU.

Upper Construction and Durability

The upper material protects the foot from falling objects and fluid splashes. The choice here defines the trade-off between waterproofing and breathability.

Leather

Leather remains a top choice due to its unique combination of breathability and durability.

It molds to the foot over time for comfort but requires proper treatment to maintain resistance against heavy oil saturation.

Rubber Uppers

For environments with standing fluids, rubber uppers offer superior water and chemical resistance.

They provide a near-impermeable barrier against leaks and spills, though they offer less breathability than leather or nylon.

Nylon

Nylon is utilized for its lightweight and breathable properties.

It reduces the overall weight of the boot, making it suitable for active roles where agility is required, provided heavy chemical splashes are not a constant threat.

Internal Safety Components

Beyond chemical resistance, physical protection is required for heavy industrial use.

Steel Toes

Steel offers the highest level of protection against crushing injuries from heavy objects or machinery.

However, it adds significant weight to the boot and conducts temperature, which may be an issue in extreme climates.

Composite Toes

Composite materials provide structural integrity and impact protection similar to steel but are significantly lightweight.

They do not conduct electricity, making them safer for environments with electrical hazards.

Understanding the Limitations

Even high-quality materials have performance boundaries. Understanding these limitations is critical for maintaining safety standards.

Chemical Degradation

No material is impervious forever. Prolonged exposure to aggressive oils or solvents can eventually cause permanent damage to the non-slip surface.

Regular inspection is necessary, as chemical breakdown often happens invisibly before a failure occurs.

The "Non-Slip" Reality

While materials like TPU and Rubber are designed to prevent slips, they cannot guarantee traction in extremely slippery conditions.

Users must remain vigilant, as a layer of oil on a smooth surface can compromise the friction of even the best outsole.

Making the Right Choice for Your Goal

Selecting the correct boot requires matching the material properties to your specific daily hazards.

- If your primary focus is heavy oil saturation: Prioritize Rubber or TPU soles with a Rubber upper to create an impermeable barrier against fluids.

- If your primary focus is reducing fatigue: Look for boots utilizing EVA midsoles and Nylon or Leather uppers to minimize weight while maintaining stability.

- If your primary focus is physical impact safety: Ensure the boot incorporates a Steel or Composite toe cap to protect against dropping heavy objects or machinery operation.

The correct material combination transforms your footwear from a simple accessory into a critical layer of industrial defense.

Summary Table:

| Material | Primary Use | Key Property |

|---|---|---|

| Rubber | Outsole/Upper | Excellent oil resistance & durability |

| TPU | Outsole | Lightweight, flexible, and oil resistant |

| Leather | Upper | Durable, breathable, molds to foot |

| Nylon | Upper | Lightweight and breathable |

| Steel/Composite | Toe Cap | Impact protection (steel is heavier, composite is lighter) |

| EVA | Midsole | Provides stability and comfort, reduces fatigue |

Need reliable, high-performance oil resistant safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial boots, ensuring you get the perfect combination of materials—like oil-resistant rubber or TPU outsoles and durable leather uppers—tailored to your specific workplace hazards.

We help you enhance workplace safety with durable, compliant footwear that protects your workforce and your bottom line.

Contact our experts today for a quote and discover the 3515 advantage!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do ASTM F2412 and ASTM F2413 standards differ? A Guide to Safety Footwear Compliance

- How is compliance with the EN ISO 20345 standard certified? The Path to Independent Verification

- How does the implementation of standardized safety footwear impact OHS in plantations? Boost Safety & Output

- What are the benefits of low-profile correction clips for safety shoes? Enhance Comfort in Industrial & Tactical Boots

- How does a thermoset toe box provide protection? Essential Safety Insights for High-Performance Work Shoes

- What materials are used in composite toe caps? Discover the Lightweight, Non-Metallic Safety Advantage

- What are the primary ergonomic design objectives of industrial-grade Safety Shoes? Enhancing Worker Comfort and Health

- How does the protective capability of composite safety shoes compare to steel toed boots? Choose the Right Protection for Your Job