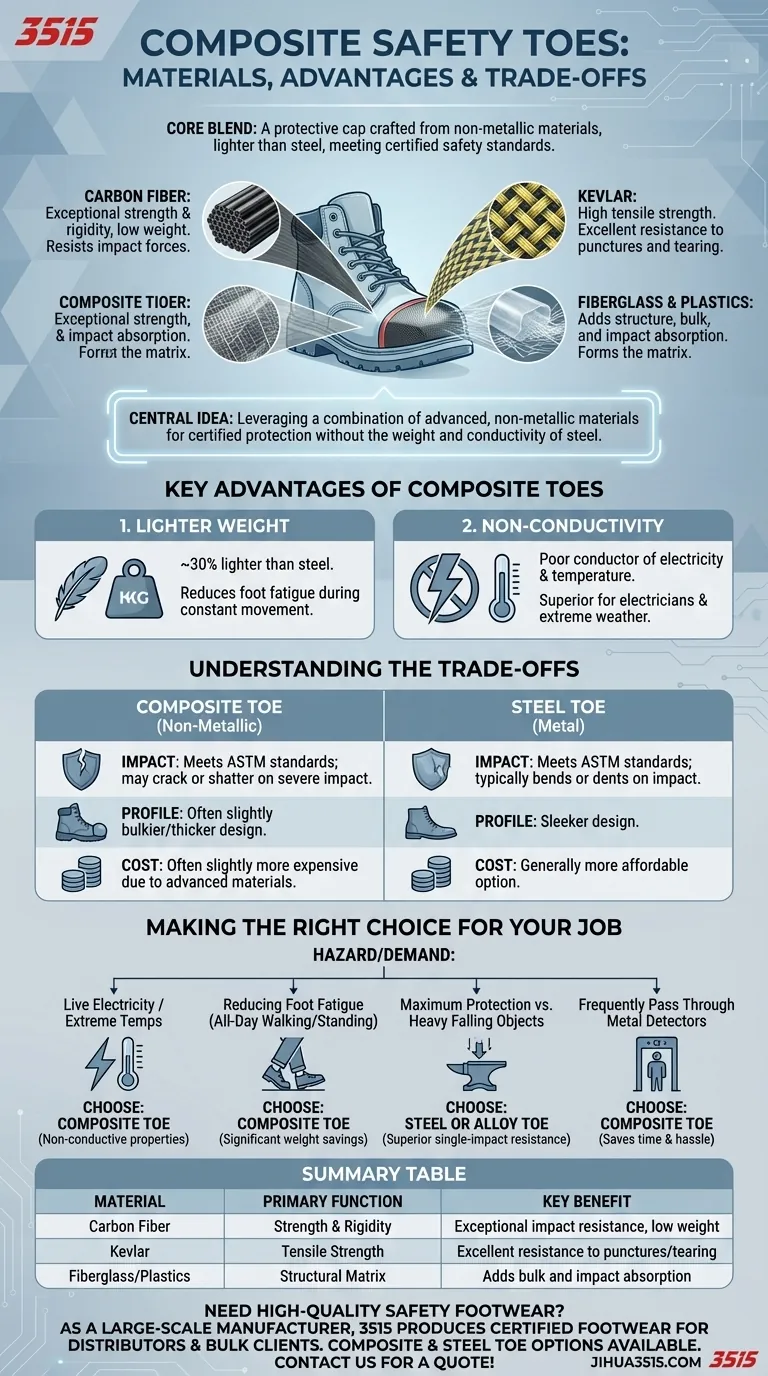

At their core, composite safety toes are crafted from a blend of non-metallic materials, primarily including fiberglass, plastic, carbon fiber, and Kevlar. This combination creates a protective cap that is significantly lighter than traditional steel while still meeting certified safety standards for impact and compression.

The central idea behind composite safety toes is not to use a single "strong" material, but to leverage a combination of advanced, non-metallic materials to achieve certified protection without the weight and conductivity of steel.

Why Composite Materials are Used

The shift from steel to composite materials in safety footwear is driven by specific occupational needs. It's about optimizing for more than just raw impact resistance.

The Role of Each Material

- Carbon Fiber: This material provides exceptional strength and rigidity at a very low weight. It's a primary component for resisting impact forces.

- Kevlar: Known for its use in ballistic and stab-resistant body armor, Kevlar offers high tensile strength, meaning it's excellent at resisting being pulled apart or punctured.

- Fiberglass & Plastics: These materials add structure, bulk, and impact absorption to the composite blend, often forming the matrix that holds the stronger fibers together.

The Key Advantage: Lighter Weight

The most immediate benefit is a noticeable reduction in weight. Composite safety toes are approximately 30% lighter than their steel counterparts.

This reduction in weight directly translates to less foot fatigue over a long workday, which is a significant factor in professions requiring constant movement.

The Secondary Advantage: Non-Conductivity

Unlike steel, the materials used in composite toes are poor conductors of electricity and temperature.

This makes them the superior choice for electricians or anyone working in environments with a risk of electrical hazards. It also means they won't transfer extreme cold or heat to the foot, providing better comfort in severe weather conditions.

Understanding the Trade-offs

Choosing a composite toe is not without its compromises. While it excels in certain areas, it has limitations compared to metal alternatives like steel or alloy.

Impact Resistance

The primary trade-off is in ultimate impact strength. While all certified safety toes (composite or steel) must pass the same ASTM standards, steel can typically withstand a single, heavier impact before failing.

After a significant impact, a composite toe may crack or shatter, and the footwear must be replaced. Steel is more likely to bend or dent but may still offer some residual protection.

Bulk and Profile

To achieve the required level of protection, composite caps often need to be slightly bulkier or thicker than steel or alloy caps.

This can affect the overall look and fit of the boot, sometimes resulting in a more "bulbous" toe box area compared to a sleeker steel-toed design.

Cost Considerations

The advanced materials and manufacturing processes involved can sometimes make composite-toed footwear slightly more expensive than equivalent steel-toed options.

Making the Right Choice for Your Job

Your decision should be based entirely on the specific hazards and demands of your work environment.

- If your primary focus is working around live electricity or in extreme temperatures: Choose composite toes for their non-conductive properties.

- If your primary focus is reducing foot fatigue from walking or standing all day: The significant weight savings of composite toes make them the ideal choice.

- If your primary focus is maximum protection against heavy falling objects: Steel or alloy toes generally offer superior single-impact resistance.

- If you frequently pass through metal detectors: Composite toes will save you significant time and hassle.

Ultimately, understanding the material composition allows you to select safety footwear that is not just compliant, but perfectly suited to your daily tasks.

Summary Table:

| Material | Primary Function | Key Benefit |

|---|---|---|

| Carbon Fiber | Provides strength & rigidity | Exceptional impact resistance at low weight |

| Kevlar | Adds tensile strength | Excellent resistance to punctures and tearing |

| Fiberglass/Plastics | Forms structural matrix | Adds bulk and impact absorption |

| Feature | Composite Toe | Steel Toe |

|---|---|---|

| Weight | ~30% lighter | Heavier |

| Conductivity | Non-conductive (safe for electricians) | Conducts electricity and temperature |

| Impact Resistance | Meets ASTM standards; may crack on severe impact | Meets ASTM standards; may dent but retain shape |

Need High-Quality Safety Footwear with Composite Toes?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We offer both composite and steel toe options, ensuring you get the perfect balance of protection, comfort, and compliance for your workforce.

Our production capabilities encompass all types of safety shoes and boots. Let us help you equip your team with the right gear.

Contact us today for a quote and to discuss your specific needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do Weather-resistant safety boots perform in different conditions? Find the Right Boot for Your Job

- How do safety shoes and puncture-resistant boots protect against snakebites? Secure Your Field Workers with 3515 Gear

- Why are specialized safety shoes necessary in garment processing? Protect Against Needles and Slips Effectively

- What are the different types of protection standards for safety footwear? Decode ASTM & EN ISO Standards

- How do safety shoes promote stability and ankle support? Secure Your Stance on Any Terrain

- How can spatial grouping analysis tools be used to optimize the production layout for safety shoes and tactical boots?

- What standards must safety shoes meet for OSHA compliance? A Guide to ASTM F2413 Labels

- Why is it necessary to distinguish between indoor and outdoor designs for specialized protective footwear?