For a chef shoe to be truly durable, it must be constructed from a system of specialized materials, not just one. The most common choices are high-grade synthetic leather for the upper, supportive EVA or polyurethane for the midsole, and slip-resistant rubber compounds for the outsole, each chosen for its ability to withstand the unique hazards of a professional kitchen.

The durability of a chef shoe is not determined by a single material, but by the strategic combination of materials across its three key sections—the protective upper, the supportive midsole, and the high-traction outsole—working together to provide safety, comfort, and longevity.

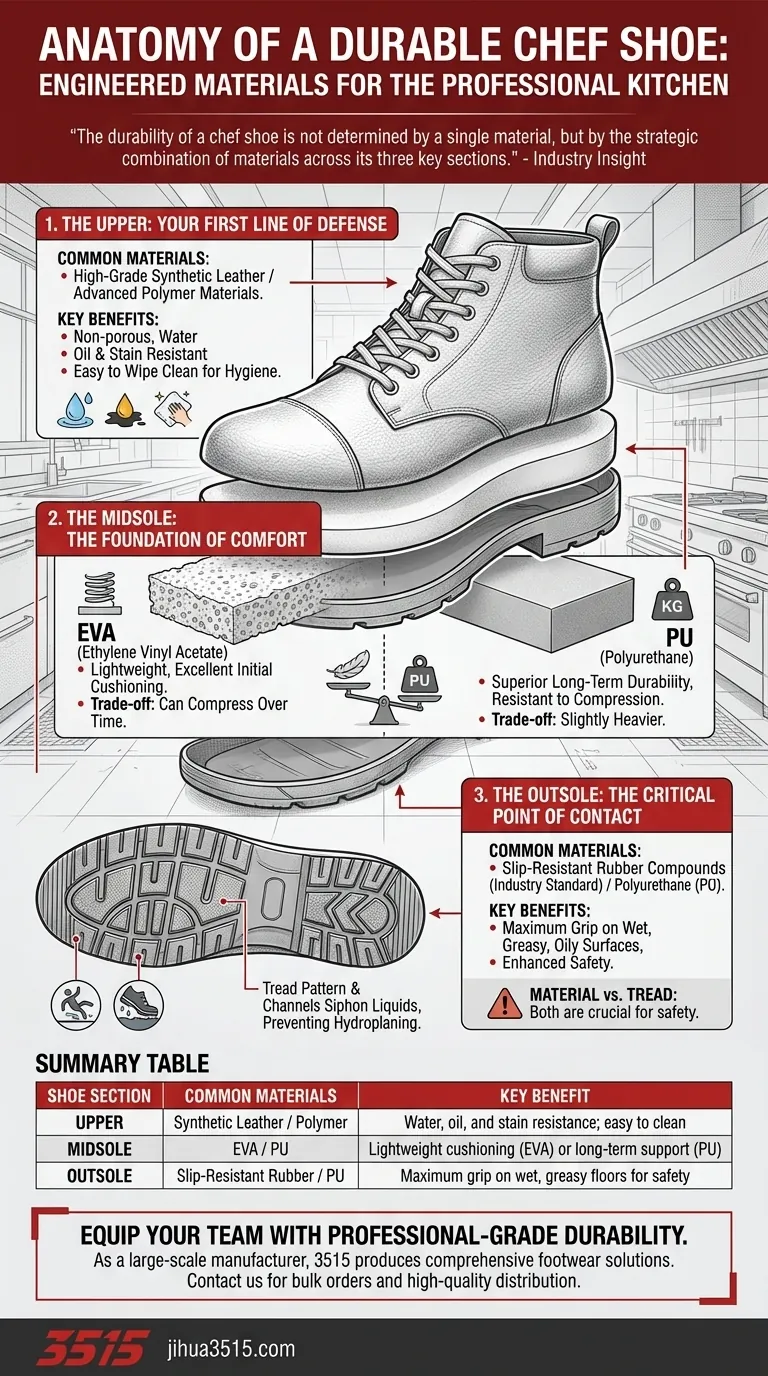

The Anatomy of a Durable Chef Shoe

A high-performance chef shoe is an engineered tool. Understanding its construction reveals why specific materials are chosen for each part of the shoe to meet the intense demands of daily kitchen use.

The Upper: Your First Line of Defense

The upper section is what wraps your foot, providing the primary barrier against spills, heat, and impacts.

Most modern, durable chef shoes use synthetic leather or other advanced polymer materials. These are favored over natural leather because they are non-porous, making them highly resistant to water, oil, and stains.

This synthetic construction makes the shoes exceptionally easy to wipe clean, a critical feature for maintaining hygiene and appearance in a food service environment.

The Midsole: The Foundation of Comfort

The midsole is the hidden layer between your foot and the outsole, responsible for cushioning and shock absorption during long hours of standing.

The two most common materials are EVA (Ethylene Vinyl Acetate) and PU (Polyurethane). EVA is a lightweight foam that provides excellent initial cushioning.

PU is a denser, slightly heavier polymer that offers superior long-term durability and resistance to compression, making it a common choice for premium work footwear.

The Outsole: The Critical Point of Contact

The outsole is the part of the shoe that contacts the floor, and its material is critical for both durability and, most importantly, safety.

Slip-resistant rubber is the industry standard. These are not generic rubbers; they are specific compounds formulated to provide maximum grip on wet, greasy, or oily surfaces.

Some outsoles also use polyurethane (PU), which offers a good balance of durability and slip resistance, though specialized rubber compounds often provide the best traction.

Understanding the Trade-offs

Choosing the right materials involves balancing competing benefits. No single material is perfect for every function, which is why understanding their inherent compromises is key.

Synthetic vs. Genuine Leather

While synthetic uppers offer superior water resistance and are easy to clean, they can sometimes be less breathable than genuine leather. However, for most kitchen environments, the protection from liquids far outweighs the need for maximum breathability.

EVA vs. Polyurethane (PU) Midsoles

The primary trade-off in midsoles is between weight and longevity. EVA offers a lighter, more athletic feel but can compress and lose its cushioning over time. PU is more resilient and will maintain its supportive structure for much longer, but at the cost of slightly more weight.

Material vs. Tread Pattern

An outsole made from the best slip-resistant rubber is only effective if it has a proper tread pattern. The material provides the grip, but the channels and grooves of the tread are what siphon liquids away from the point of contact, preventing hydroplaning and ensuring the rubber can connect with the floor.

Making the Right Choice for Your Goal

Selecting the right shoe means matching its material composition to your most critical needs in the kitchen.

- If your primary focus is maximum protection and easy cleaning: Prioritize a shoe with a seamless, non-porous synthetic leather or polymer upper.

- If your primary focus is all-day comfort for long shifts: Look for a shoe with a thick PU midsole or a dual-density EVA foam for sustained support.

- If your primary focus is safety on wet or oily floors: Insist on a certified slip-resistant rubber outsole with a deep, liquid-channeling tread pattern.

Understanding these core materials empowers you to select a shoe that is not just a uniform requirement, but a professional tool engineered for performance.

Summary Table:

| Shoe Section | Common Materials | Key Benefit |

|---|---|---|

| Upper | Synthetic Leather / Polymer | Water, oil, and stain resistance; easy to clean |

| Midsole | EVA (Ethylene Vinyl Acetate) / PU (Polyurethane) | Lightweight cushioning (EVA) or long-term support (PU) |

| Outsole | Slip-Resistant Rubber / PU | Maximum grip on wet, greasy floors for safety |

Ready to equip your team with professional-grade chef shoes?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear designed specifically for the demanding kitchen environment. We work directly with distributors, brand owners, and bulk clients to deliver high-quality shoes and boots that combine safety, comfort, and longevity.

Contact our team today to discuss your footwear needs and discover how we can support your business with reliable, high-performance solutions.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

People Also Ask

- Why is durability important in work shoes? Ensure Safety and Reduce Long-Term Costs

- What industries should enforce slip resistant footwear? A Guide to High-Risk Workplaces

- Why are slip resistant shoes important in the workplace? Prevent Costly Accidents & Protect Your Team

- How can you tell if shoes are slip-resistant when shopping online? A Practical Guide to Safety

- How do I make sure my shoes are non-slip? DIY Fixes vs. Engineered Safety

- What types of slip-resistant shoes are available for women? Find the Perfect Fit for Safety & Style

- What combination of features prevents non-slip shoes from slipping? The Science of Sole Material, Tread, and Liquid Displacement

- What is the cost consideration when choosing between slip-resistant shoes and everyday sneakers? Avoid the False Economy