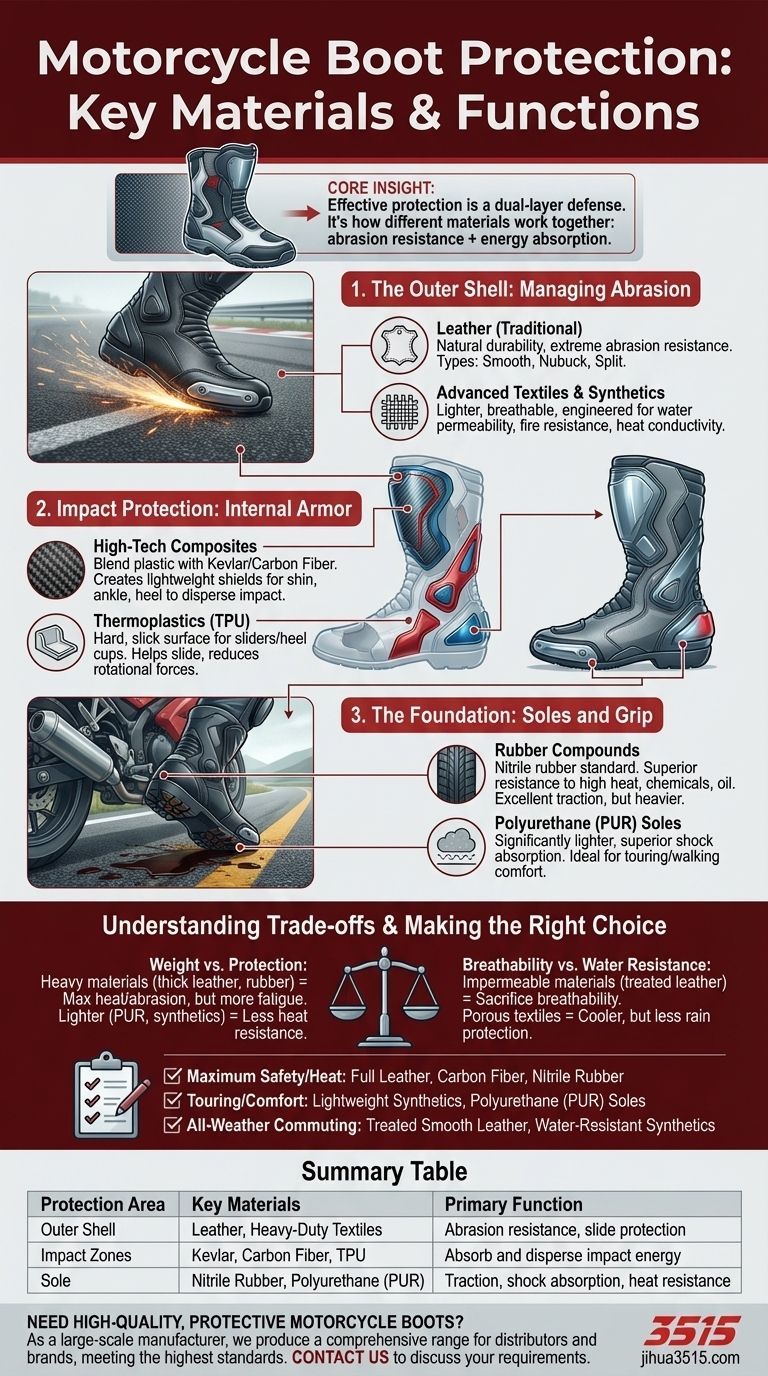

Motorcycle boots rely on a combination of materials to provide a dual-layer defense system: leather and heavy-duty textiles for abrasion resistance, and reinforced composites like Kevlar, carbon fiber, and thermoplastics for impact protection. While the upper chassis is typically constructed from leather or synthetic alternatives to survive a slide, the internal structure and soles utilize specialized plastics and rubbers to absorb shock and maintain structural integrity.

Core Insight: Effective protection is not about a single tough material, but how different materials work together. The ideal boot marries the high abrasion resistance of the outer shell with the energy-absorbing capabilities of the internal composites and sole.

The Outer Shell: Managing Abrasion

The primary job of the boot's exterior is to prevent road rash and withstand the intense friction of a fall.

Leather: The Traditional Standard

Leather remains the most common material for the boot's upper chassis due to its natural durability and extreme abrasion resistance. Manufacturers typically use smooth, nubuck, or split leather depending on the desired finish and flexibility.

Advanced Textiles and Synthetics

Modern boots often incorporate synthetic materials to reduce weight and improve breathability. These textiles are engineered for specific characteristics, such as water permeability, fire resistance, and heat conductivity, offering a cooler alternative to leather without sacrificing safety standards.

Impact Protection: The Internal Armor

Beneath the surface, rigid materials are necessary to prevent crushing injuries and limit hyperextension of the ankle.

High-Tech Composites

To create rigid protective zones around the shin, ankle, and heel, manufacturers utilize composite materials. These often blend plastic with high-strength fibers like Kevlar aramid fiber and carbon fiber to create lightweight shields that disperse impact energy.

Thermoplastics (TPU)

Thermoplastic Polyurethane is frequently used for external sliders and heel cups. It provides a hard, slick surface that helps the boot slide rather than catch on the pavement, reducing the rotational forces that cause bone fractures.

The Foundation: Soles and Grip

The outsole determines how the boot interacts with the bike's pegs and the road surface, playing a crucial role in shock absorption.

Rubber Compounds

Nitrile rubber is a standard choice for outsoles because of its superior resistance to high heat and chemicals, such as oil or gasoline found on road surfaces. It provides excellent traction but can be heavier than synthetic alternatives.

Polyurethane (PUR) Soles

For riders prioritizing comfort and weight reduction, Polyurethane (PUR) soles are a common alternative. PUR is significantly lighter than rubber and offers superior shock absorption, making it ideal for touring boots where walking is required.

Understanding the Trade-offs

No single material is perfect for every scenario; choosing the right boot requires balancing protection against comfort and utility.

Weight vs. Protection

Heavy-duty materials like thick leather and rubber soles offer maximum heat and abrasion resistance but can increase fatigue. Conversely, PUR soles and synthetic uppers are lighter but may offer lower heat resistance compared to vulcanized rubber.

Breathability vs. Water Resistance

Materials chosen for their water impermeability (like treated leather or specific synthetics) often sacrifice breathability. While excellent for rain, they can lead to overheating in hot weather compared to lighter, porous textiles.

Making the Right Choice for Your Goal

Select your gear based on the environment you ride in and the specific risks you face.

- If your primary focus is Maximum Safety and Heat Resistance: Prioritize boots with a full leather construction, carbon fiber reinforcement, and nitrile rubber soles.

- If your primary focus is Touring and Walking Comfort: Look for boots utilizing lightweight synthetic textiles and Polyurethane (PUR) outsoles for better shock absorption.

- If your primary focus is All-Weather Commuting: Choose footwear featuring treated smooth leather or specialized water-resistant synthetics to manage moisture and road grime.

The best material for your boots is the one that aligns with your specific riding style while ensuring the protective barrier remains uncompromised.

Summary Table:

| Protection Area | Key Materials | Primary Function |

|---|---|---|

| Outer Shell | Leather, Heavy-Duty Textiles | Abrasion resistance, slide protection |

| Impact Zones | Kevlar, Carbon Fiber, TPU | Absorb and disperse impact energy |

| Sole | Nitrile Rubber, Polyurethane (PUR) | Traction, shock absorption, heat resistance |

Need high-quality, protective motorcycle boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots, ensuring your inventory meets the highest standards of protection, durability, and comfort.

Contact us today to discuss your specific requirements and leverage our manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What role does ultrasonic dispersion equipment play in CPL-GO solutions? Achieve Perfect Nanomaterial Homogeneity

- What are the advantages of online survey tools for large-scale footwear market research? Speed Up Your Strategy Cycle

- What is Peak Amplitude in GRF for Footwear Design? Optimize Cushioning and Protection

- What is the function of a centralized digital management platform in green factory operations? Unlock Efficiency Now

- Why is it necessary to add film-based protective materials during the post-processing of E-TPU basketball shoe soles?

- What role do industrial-grade high-precision plantar pressure systems play in medical device development?

- Why is digital blood pressure monitoring necessary in footwear stress tests? Quantifying Cardiovascular Safety

- Can Cordura items be machine washed? Yes, but follow these key rules to protect your gear.