The material of your work shoe upper is the single most important factor determining its durability, comfort, and performance in a specific environment. The most common materials are various types of leather, known for their toughness, and advanced synthetic fabrics like nylon and mesh, valued for their lightweight and specialized properties.

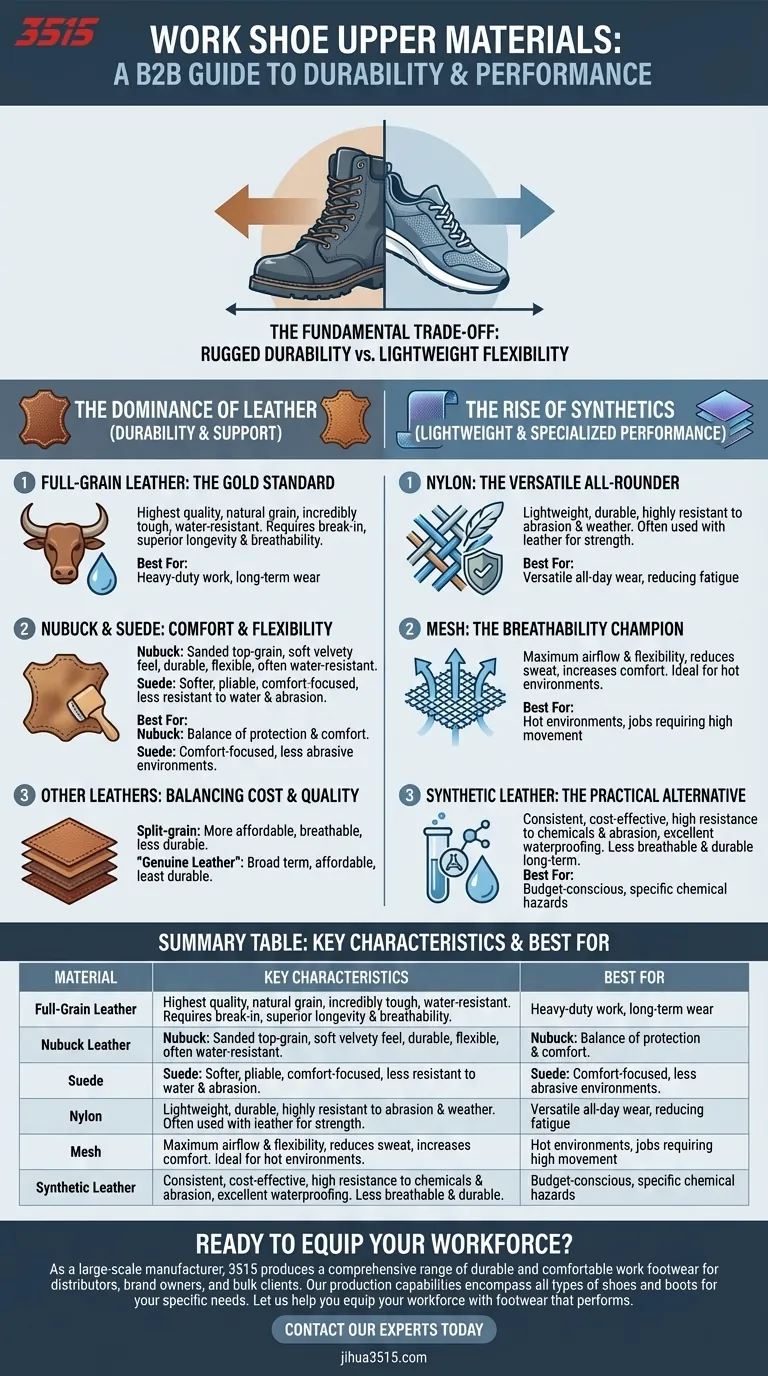

The choice of a work shoe upper is fundamentally a trade-off. You are typically balancing the rugged, long-term durability of leather against the lightweight flexibility and specialized performance of modern synthetic materials.

The Dominance of Leather: Durability and Support

Leather has long been the standard for work footwear due to its exceptional strength, support, and ability to mold to the wearer's foot over time. It provides a protective barrier that is difficult to replicate.

Full-Grain Leather: The Gold Standard

Full-grain leather is the highest quality and most durable type available. It comes from the top layer of the hide and includes all the natural grain, making it incredibly tough and water-resistant. While it requires a break-in period, it offers superior longevity and breathability.

Nubuck and Suede: Comfort and Flexibility

Nubuck is a type of top-grain leather that has been sanded on the outer surface to create a soft, velvety feel. It maintains much of the durability of full-grain leather but is more flexible and is often treated for excellent water resistance.

Suede is created from the inner split of the hide, making it softer and more pliable than nubuck. It is often used for comfort and aesthetic accents but is less resistant to water and abrasion.

Other Leathers: Balancing Cost and Quality

Split-grain leather is created from the lower layers of the hide after the top-grain is removed. It is more affordable and breathable but less durable and water-resistant than full-grain leather.

"Genuine leather" is a broad term for leather that is not top-grain or nubuck. It is one of the most affordable options but offers the least durability of the leather types.

The Rise of Synthetics: Lightweight and Specialized Performance

Synthetic materials have revolutionized work footwear by offering lightweight alternatives that excel in specific conditions. They often provide excellent performance right out of the box with no break-in period required.

Nylon: The Versatile All-Rounder

Nylon fabric is prized for being lightweight, durable, and highly resistant to abrasion and weather. It is often used in combination with leather to reduce weight while maintaining strength in critical areas.

Mesh: The Breathability Champion

Mesh is incorporated into uppers to provide maximum airflow and flexibility. This makes it ideal for work in hot environments or for jobs that require a high degree of movement, reducing sweat and increasing comfort.

Synthetic Leather: The Practical Alternative

Synthetic leather offers a consistent, cost-effective alternative to real leather. Its primary advantages are its high resistance to chemicals and abrasion, as well as its excellent waterproofing capabilities. However, it is typically less breathable and durable over the long term than high-quality natural leather.

Understanding the Trade-offs

No single material is perfect for every job. The right choice depends on understanding the inherent compromises between different properties.

Durability vs. Weight

Full-grain leather offers unparalleled durability for heavy-duty work but is the heaviest option. Synthetics like nylon and mesh drastically reduce the shoe's weight, which can lessen fatigue, but may not withstand the same level of abuse over several years.

Water Resistance vs. Breathability

Materials like treated leather and non-porous synthetics provide excellent protection from water and chemicals. The downside is that they can trap heat and sweat. Highly breathable mesh uppers keep your feet cool and dry from the inside but offer little protection from external moisture.

Cost vs. Longevity

High-quality leathers, particularly full-grain, represent a significant upfront investment but can last for many years with proper care. Synthetic and lower-grade leather options are more affordable but will likely need to be replaced sooner.

Making the Right Choice for Your Goal

Select an upper material that directly addresses the primary demands of your workday.

- If your primary focus is maximum durability and job-site protection: Choose full-grain leather for its unmatched strength and longevity.

- If your primary focus is lightweight comfort and staying cool: Look for uppers made of nylon, mesh, or a combination of synthetics and split-grain leather.

- If your primary focus is a balance of performance and water resistance: Nubuck leather or a hybrid boot combining leather and nylon panels is an excellent choice.

Understanding these material properties empowers you to select a work shoe that functions as a true tool for your specific job.

Summary Table:

| Material | Key Characteristics | Best For |

|---|---|---|

| Full-Grain Leather | Maximum durability, excellent support, water-resistant | Heavy-duty work, long-term wear |

| Nubuck Leather | Durable, flexible, often water-resistant | Balance of protection and comfort |

| Suede | Soft, pliable, comfortable | Comfort-focused, less abrasive environments |

| Nylon | Lightweight, durable, weather-resistant | Versatile all-day wear, reducing fatigue |

| Mesh | Highly breathable, flexible, lightweight | Hot environments, jobs requiring high movement |

| Synthetic Leather | Cost-effective, chemical/abrasion resistant, waterproof | Budget-conscious, specific chemical hazards |

Ready to Find the Perfect Work Shoe for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and comfortable work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right combination of materials, safety features, and value for your specific needs.

Let us help you equip your workforce with footwear that performs.

Contact our experts today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health