To answer your question directly, riding boots are most commonly made from genuine leather, synthetic leather, rubber, and textiles like canvas. The specific material used is chosen to balance durability, rider comfort, performance requirements, and budget.

The material of a riding boot is not merely a stylistic choice; it is a functional one. The core decision involves a trade-off between the classic performance and breathability of leather, the easy maintenance of synthetics, and the rugged, weatherproof nature of rubber.

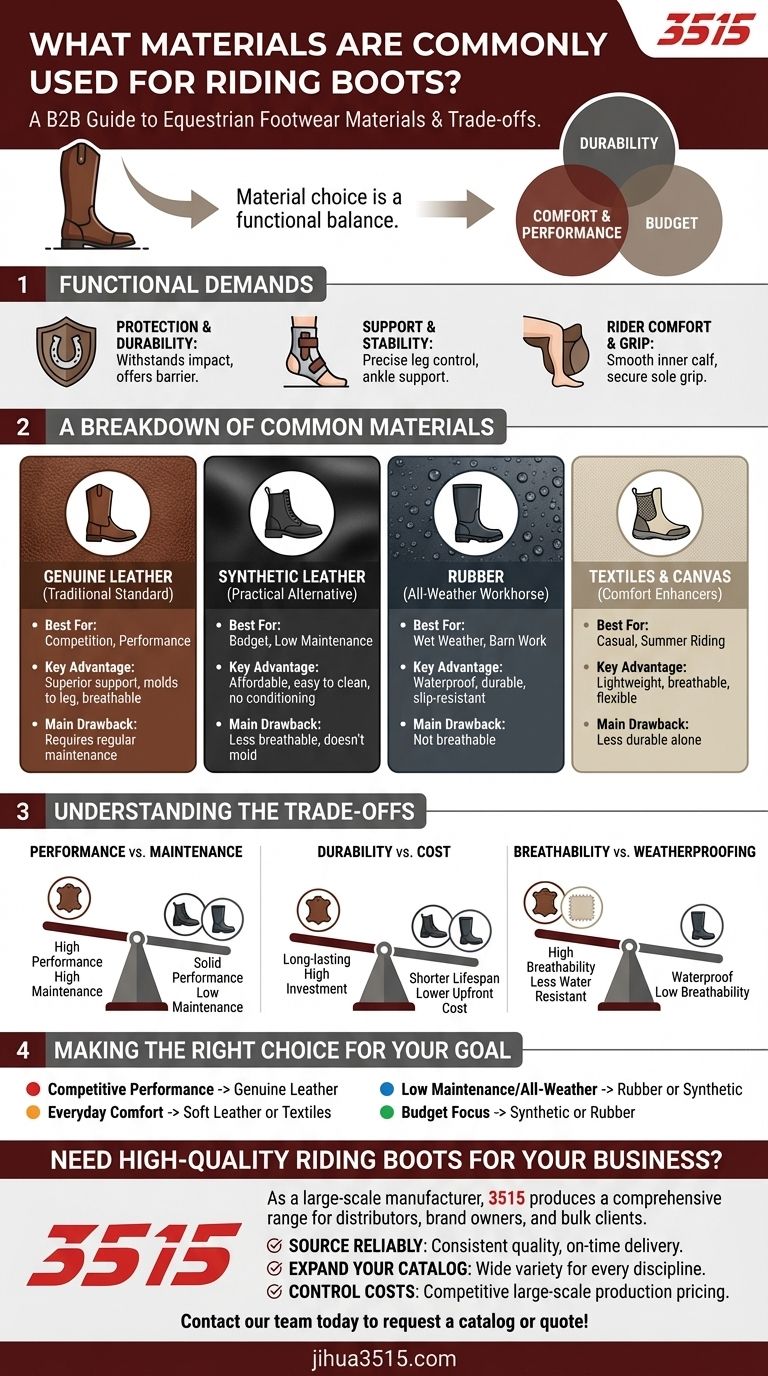

The Functional Demands of a Riding Boot

Before comparing materials, it's crucial to understand what a riding boot is designed to do. Its construction is a direct response to the specific demands of equestrian activities.

Protection and Durability

A boot must be tough enough to withstand accidental knocks or the immense pressure of being stepped on by a horse's hoof. The material needs to offer a protective barrier for the rider's foot and leg.

Support and Stability

Riding requires precise leg control. A well-constructed boot provides firm but comfortable support for the ankle and lower leg, helping to prevent strains and maintain the correct riding position.

Rider Comfort and Grip

The boot's inner calf must be smooth yet durable to protect the rider's leg from rubbing against the saddle and tack. The sole also requires a good grip to prevent the foot from slipping in the stirrup.

A Breakdown of Common Boot Materials

Each material offers a distinct set of advantages and disadvantages tailored to different types of riding, weather conditions, and levels of care.

Genuine Leather (The Traditional Standard)

Leather is the benchmark material for riding boots due to its unique combination of strength and flexibility. It is highly durable and breathable, and over time, it molds to the rider's leg for a near-custom fit.

Stiff leather is often preferred for competitions as it provides maximum support and a polished, traditional appearance. Softer leathers offer more immediate comfort for everyday riding.

Synthetic Leather (The Practical Alternative)

Also known as simulated or vegan leather, this material offers the look of leather at a lower cost and with significantly less maintenance. It is easy to clean and does not require conditioning.

While highly practical, synthetic leather typically offers less breathability than genuine leather and will not mold to the rider's leg in the same way.

Rubber (The All-Weather Workhorse)

Rubber is valued for its exceptional durability, grip, and slip resistance. Because it is waterproof, it is the ideal choice for riding in wet, muddy conditions or for daily barn chores.

The main drawback of rubber is its lack of breathability, which can make it uncomfortable for long periods or in warm weather.

Textiles and Canvas (The Comfort Enhancers)

Materials like canvas and other advanced textiles are often integrated into boot designs to enhance breathability and comfort. They are lightweight and flexible, making them a popular feature in boots designed for endurance or casual summer riding.

These materials are typically combined with leather or synthetics in key areas to ensure the boot retains the necessary durability and support.

Understanding the Trade-offs

Choosing a riding boot material is an exercise in balancing competing priorities. There is no single "best" material, only the best material for your specific situation.

Performance vs. Maintenance

Genuine leather offers superior performance in terms of fit and breathability but demands regular cleaning and conditioning to prevent it from drying out and cracking. Synthetics and rubber offer solid performance with minimal wipe-clean care.

Durability vs. Cost

High-quality leather boots are a significant investment but can last for many years with proper care. Synthetic and rubber boots are more affordable upfront but may need to be replaced sooner.

Breathability vs. Weatherproofing

Leather and textiles allow moisture to escape, keeping the rider's feet more comfortable during long rides. Rubber provides complete waterproofing at the cost of this breathability.

Making the Right Choice for Your Goal

Your ideal boot material depends entirely on your primary needs as a rider.

- If your primary focus is competitive performance: Choose a stiff, genuine leather boot for its unparalleled support, classic appearance, and custom-like fit over time.

- If your primary focus is everyday comfort: Look for boots made from soft leather or those incorporating breathable textile panels.

- If your primary focus is low maintenance and all-weather use: Select boots made from rubber or synthetic leather for their durability and ease of care.

- If your primary focus is budget: Synthetic leather and rubber boots provide a safe and functional entry point into the sport without a major financial commitment.

Ultimately, the right boot is the one that provides the safety and support you need in a material that fits your lifestyle and riding discipline.

Summary Table:

| Material | Best For | Key Advantage | Main Drawback |

|---|---|---|---|

| Genuine Leather | Competition, Performance | Superior support, molds to leg | Requires regular maintenance |

| Synthetic Leather | Budget, Low Maintenance | Affordable, easy to clean | Less breathable |

| Rubber | Wet Weather, Barn Work | Waterproof, durable | Not breathable |

| Textiles/Canvas | Casual, Summer Riding | Lightweight, breathable | Less durable alone |

Need High-Quality Riding Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of equestrian footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of riding boots, from premium leather competition boots to durable rubber work boots.

We help you:

- Source Reliably: Get consistent quality and on-time delivery.

- Expand Your Catalog: Offer a wide variety of boots for every riding discipline.

- Control Costs: Benefit from competitive pricing through efficient large-scale production.

Let's discuss your specific needs. Contact our team today to request a catalog or get a quote!

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the advantages of tall motorcycle boots? Maximum Protection & Style for Serious Riders

- Why are waterproof boots important for outdoor activities or wet conditions? Essential Protection for Safety & Comfort

- What is the technical value of TENG sensors in smart sports footwear? Revolutionize Energy & Biomechanical Data

- What are the key elements in making boots waterproof? A Complete System Guide

- Why might someone prefer all-leather boots over other types? For Unmatched Durability & a Custom Fit

- Why are hunting boots important for hunters? The Key to Safety, Stealth, and Success

- How do lightweight training or outdoor boots contribute to railway safety? Reduce Fatigue & Prevent Negligence

- What are the recommended colors for alpine boots? Master Versatility and Style