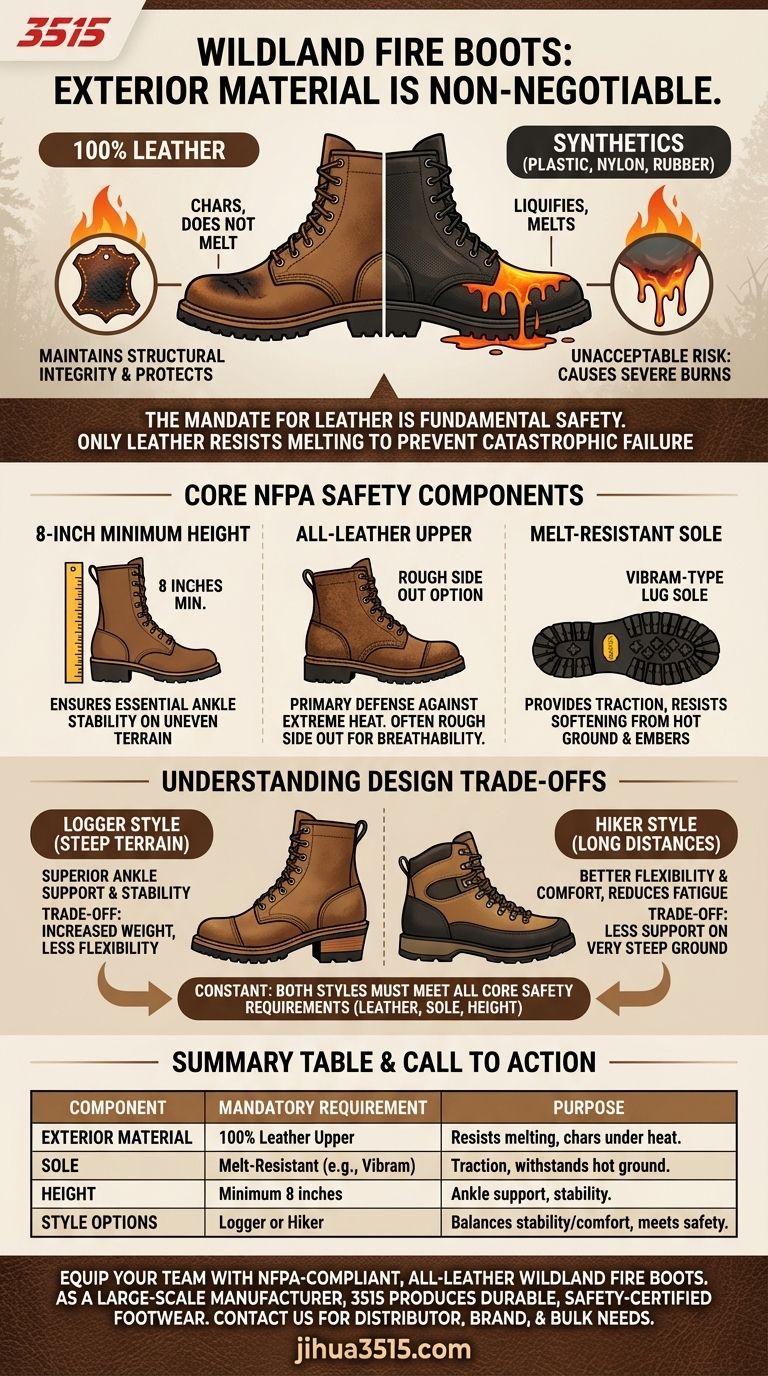

For wildland firefighting, the exterior of your boots must be made entirely of leather. This is a non-negotiable safety requirement, as leather is uniquely capable of maintaining its structural integrity and resisting extreme heat without melting, a critical failure point for synthetic materials.

The mandate for leather exteriors is not a matter of tradition but of fundamental safety. While soles and overall design are crucial, the boot's upper material is the first line of defense against heat, and only leather provides the necessary resistance to melting that prevents catastrophic failure and severe injury.

The Critical Role of Leather Construction

Understanding why leather is the only acceptable material for the boot's exterior reveals the core safety principles behind wildland footwear. The choice is a direct response to the hazardous environment where these boots operate.

Why Leather is Non-Negotiable

Leather offers exceptional durability and, most importantly, maintains its form when exposed to high temperatures. It will char rather than liquify, continuing to provide a protective barrier for the foot even under thermal stress.

The Unacceptable Risk of Synthetics

Materials like plastic, nylon, and certain types of rubber are fundamentally unsuitable for boot exteriors. When heated, these synthetic materials can liquify or melt, effectively turning into a hot, molten substance that can cause severe, deep-tissue burns.

Common Leather Finishes

Many wildland boots use a "rough side out" leather construction. This is not just for aesthetics; the textured surface can help with breathability and cooling, a significant factor during long hours of strenuous work in the heat.

Beyond the Exterior: Core Safety Components

While the leather exterior is paramount, it works in concert with other mandated features to create a fully protective system. These components are typically defined by NFPA (National Fire Protection Association) standards.

The Melt-Resistant Sole

The boot must be equipped with a melt-resistant, Vibram-type sole. This is a heavy-duty rubber lug sole specifically designed to provide traction on difficult terrain and resist softening or damage from contact with hot ground and embers.

Mandatory 8-Inch Height

NFPA-compliant wildland boots must measure a minimum of 8 inches from the bottom of the heel to the top of the boot. This height provides essential ankle stability, preventing sprains and other injuries when navigating steep or uneven ground.

Integrated Design for Performance

Modern wildland boots blend rugged safety features with elements from athletic and hiking footwear. This results in a boot that is not only protective but also flexible enough for the varied stances and movements required during firefighting operations.

Understanding the Design Trade-offs

Within the strict safety guidelines, wildland boots are generally available in two primary styles: logger and hiker. The choice between them involves trade-offs in stability, comfort, and application.

The Logger Style

Logger-style boots typically feature a more pronounced, higher heel. This design excels at providing stability and arch support, particularly when working on very steep terrain. The trade-off can sometimes be increased weight and less flexibility for walking on flat ground.

The Hiker Style

Hiker-style boots have a lower profile heel and often incorporate more design features from modern hiking footwear. They are generally more flexible and comfortable for covering long distances on foot over moderate terrain, reducing overall fatigue.

The Constant: Safety is Never a Trade-off

Regardless of whether you choose a logger or hiker style, the core safety requirements do not change. Both must be built with an all-leather exterior, a melt-resistant sole, and meet the 8-inch height requirement to be considered true wildland fire boots.

Making the Right Choice for Your Goal

Selecting the appropriate boot depends entirely on the terrain and the nature of your work, but the foundation of safety remains constant.

- If your primary focus is working on steep, rugged terrain: A logger-style boot will provide superior ankle support and stability.

- If your primary focus is covering long distances on moderate ground: A hiker-style boot offers better flexibility and comfort, which helps minimize fatigue.

- If your primary focus is ensuring absolute safety and compliance: Verify that any boot, regardless of style, is NFPA-certified and built with the non-negotiable components of a full leather upper and a melt-resistant sole.

Ultimately, understanding these material and design principles ensures your equipment provides uncompromising protection when it matters most.

Summary Table:

| Component | Mandatory Requirement | Purpose |

|---|---|---|

| Exterior Material | 100% Leather Upper | Resists melting, chars instead of liquifying under extreme heat. |

| Sole | Melt-Resistant (e.g., Vibram-type) | Provides traction and withstands hot ground/embers. |

| Height | Minimum 8 inches (heel to top) | Ensures ankle support and stability on uneven terrain. |

| Style Options | Logger (steep terrain) or Hiker (long distances) | Balances stability and comfort while meeting safety standards. |

Ensure your team is equipped with NFPA-compliant, all-leather wildland fire boots. As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities include logger and hiker-style boots built to withstand extreme conditions. Contact us today to discuss your specific needs and benefit from our expertise in protective footwear manufacturing.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- Why are waterproof Wellington work boots beneficial? Essential Protection for Wet and Demanding Work Environments

- What should be considered when choosing moc toe boots for casual wear? Find Your Perfect Fit & Style

- What types of workers commonly use Wellington boots? Essential Footwear for Demanding Professions

- What are the key parts of a work boot? A Guide to Safety, Comfort & Durability

- How do composite toe work boots handle moisture? Stay Dry and Comfortable in Wet Conditions

- What are the key features of the waterproof pull-on work boot? Superior Protection & Convenience

- What are the advantages of wedge sole work boots? Unmatched Comfort on Concrete Floors

- Why are work boots essential for risk-bearing industries? Protect Your Workforce from Severe Hazards