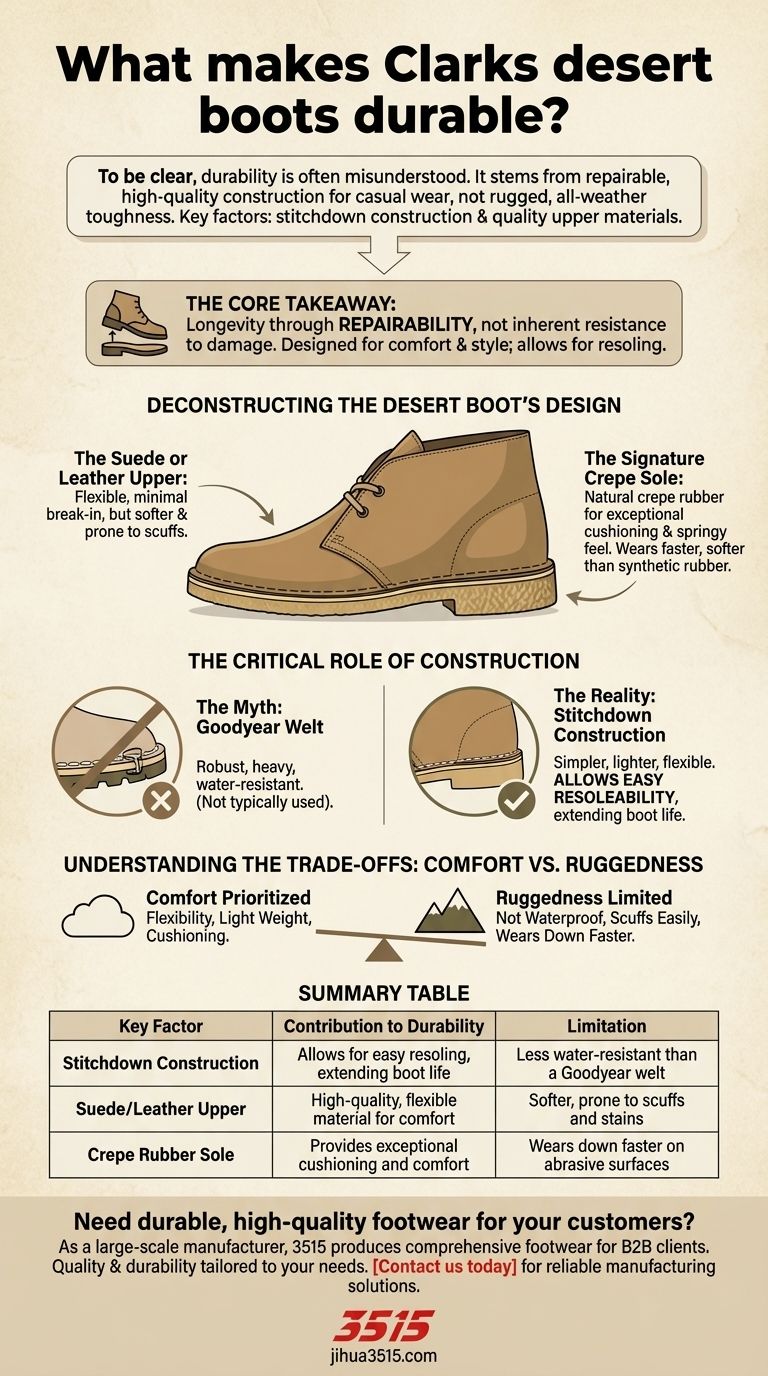

To be clear, the durability of Clarks desert boots is often misunderstood. It stems not from rugged, all-weather toughness, but from a simple, high-quality construction that allows the boot to be repaired and its life extended for its intended purpose—casual wear. Key factors include its stitchdown construction and quality upper materials, which together create a lightweight and comfortable boot that can be resoled.

The core takeaway is that a Clarks desert boot's durability is about longevity through repairability, not inherent resistance to damage. It is designed for comfort and style in casual environments, and its ability to be resoled is what allows it to last for years, despite having a sole and upper that are softer than more rugged footwear.

Deconstructing the Desert Boot's Design

To understand the boot's durability, you must first understand its core components. The design was inspired by lightweight shoes worn by officers in World War II, prioritizing comfort and traction on sand over heavy protection.

The Suede or Leather Upper

The uppers are typically made from either suede or a smooth leather. This choice of material is fundamental to the boot's character.

These materials are chosen for their flexibility and minimal break-in period. While high-quality, they are inherently softer and more prone to scuffs and stains than the thick, full-grain leather used in heavy-duty work boots.

The Signature Crepe Sole

The sole is made from natural crepe rubber, which consists of coagulated latex sheets. This material provides exceptional cushioning and a springy, comfortable feel underfoot.

It also offers excellent traction on dry surfaces. However, crepe rubber is significantly softer and more porous than the dense, synthetic rubber compounds found on tactical or hiking boots.

The Critical Role of Construction

How the upper and the sole are joined together is the most critical factor in a boot's longevity and repairability. There is a common misconception about how the Clarks desert boot is made.

The Myth of the Goodyear Welt

Some sources incorrectly state that Clarks desert boots use a Goodyear welt. This robust method involves stitching a leather strip (the "welt") to the upper and the insole, and then stitching the outsole to that welt, creating a highly durable and water-resistant seal.

The Reality: Stitchdown Construction

The classic Clarks desert boot actually uses a simpler stitchdown construction. In this method, the leather upper is turned outward and stitched directly to the outsole.

This construction is lighter and more flexible than a Goodyear welt, contributing to the boot's famous comfort. Most importantly, it allows a cobbler to easily remove the old sole and stitch on a new one once it wears out. This resoleability is the true secret to the boot's long-term durability.

Understanding the Trade-offs: Comfort vs. Ruggedness

The design of the Clarks desert boot is a masterclass in intentional trade-offs. Every element that makes it comfortable also makes it less suited for harsh conditions.

Prioritizing Flexibility and Light Weight

The combination of a soft upper, a pliable crepe sole, and stitchdown construction creates a boot that feels more like a heavy-duty sneaker than a traditional boot. This was the original intent: a boot for walking in hot, dry climates.

Where It Falls Short

This focus on comfort comes at a cost. The suede upper is not waterproof and stains easily. The soft crepe sole will wear down much faster than a hard rubber sole, especially when worn frequently on abrasive surfaces like concrete. It is not a boot for rain, snow, or rough terrain.

Making the Right Choice for Your Goal

To extend the life of your boots, proper maintenance is essential. Regular cleaning and conditioning will preserve the upper, ensuring it outlasts the original sole and is ready for a replacement.

- If your primary focus is casual style and comfort: The Clarks desert boot is an excellent choice, offering a timeless look and a flexible feel that can last for years with proper care and resoling.

- If your primary focus is all-weather, rugged durability: You should look for a boot with a Goodyear welt construction and a hard-wearing synthetic rubber sole.

Ultimately, the Clarks desert boot is a durable piece of footwear when used as intended.

Summary Table:

| Key Factor | Contribution to Durability | Limitation |

|---|---|---|

| Stitchdown Construction | Allows for easy resoling, extending boot life | Less water-resistant than a Goodyear welt |

| Suede/Leather Upper | High-quality, flexible material for comfort | Softer, prone to scuffs and stains |

| Crepe Rubber Sole | Provides exceptional cushioning and comfort | Wears down faster on abrasive surfaces |

Need durable, high-quality footwear for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring quality and durability tailored to your market needs.

Contact us today to discuss how we can support your business with reliable manufacturing solutions.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- What are the distinctive features of rain boots? Unmatched Waterproof Protection Explained

- What are the characteristics of rubber as a rain boot material? Discover Its Durability & Flexibility

- What materials are used in snow boots and rain boots? A Guide to Waterproof Footwear

- What mechanical challenges arise for protective footwear in flood transitions? Ensure Stability in Dynamic Environments

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.